Introduction

Dairy producers know the importance of getting a fresh cow off to a good start in her lactation. A considerable effort is made to ensure that she is given the utmost opportunity to consume feed and water and that all of her environmental needs are met. Production and profitability can pivot on the first few weeks of her lactation. Similarly, but not with immediate payback, calves need to be given a good start in life to ensure they will be viable replacements for the herd. Properly raised calves will be healthy, vigorous, and ready to calve between 22 and 24 months. They should be able to cope with extreme stresses better than calves raised in less than ideal conditions.

Providing adequate nutrition, health care, animal husbandry, and management is essential. Ensuring the proper environment for each animal is equally as important. The type and quality of housing facilities affect all these variables directly or indirectly. All variables should be considered when developing a management plan.

Please check this link first if you are interested in organic or specialty dairy production.

A Management Plan

Developing a management plan for raising heifers is best accomplished by looking at all related factors: nutrition, health, growth, labor efficiency, capital, and operation and maintenance costs. Weighted priorities need to be assigned to each variable in order to decide overall which are most important for your farm. Thrifty calves cannot be raised efficiently in poor facilities with inadequate animal husbandry. Great calves, with optimal daily weight gains, can be raised in ideal conditions, but this may not be economically feasible every day of the year.

The overall management plan for your farm will most likely be different from that of your neighbor. Existing conditions, site characteristics, employee knowledge, desire and capability, and your personal preference are just some of the variables that will influence each management plan.

When developing a management plan, a primary goal is to look for ways to combine calves with similar characteristics and needs to form management groups. Formation of management groups allows for increased efficiency in meeting the general needs of all group members. However, the individual need(s) of each group member can still be met as required. Management groups are used to help determine the appropriate housing characteristics. The goal of housing facilities is to serve as tools in support of the overall management plan.

Management Groups

When considering rearing dairy replacement calves, generally three distinct management groups can be formed: the newborn group, the transition group, and the adolescent group.

Newborn Group

The newborn group consists of calves from birth to about 10 days post-weaning. From a health aspect, recommendations are to raise newborn calves in individual pens, since calves need individual attention and observation during this time. Also, isolation from other calves minimizes the potential of disease spreading, and access to feed and water takes place without competition. Retaining a calf in this group for 10 days post-weaning allows for close observation of the calf to ensure the process is complete.

Transition Group

This management group encompasses post-weaned calves to about 5 to 6 months of age.

Adolescent Group

Calves that have graduated from the transition group are housed in an adolescent management group. Calves remain in this group until they enter the pre-fresh group. This paper discusses facilities for the newborn management group. It is the first in a series of three on cold, naturally ventilated housing options for raising dairy replacements. See “Transition Heifer Housing” and “Adolescent Heifer Housing” for information on providing housing for each of these management groups.

Environmental Basics

Regardless of the management group, producers must remember that calves need the following in order for them to be comfortable and healthy, allowing efficient growth year-round:

- A clean, dry, and comfortable resting area

- Adequate ventilation

- Good access to feed and water.

In addition, it is recommended that pre-weaned calves be separated from other calves to prevent calf-to-calf contact in a good calf housing system.

These elements are of paramount importance and should not be compromised or sacrificed; otherwise, calf health and growth will be negatively affected.

Resting Area

A clean, dry, and comfortable resting area is important to the health and overall well-being of calves. A generous dry bed of fluffy material such as straw, coarse sawdust, or wood shavings benefits the calf by:

- Helping the calf stay clean

- Helping maintain a fluffed hair coat for winter protection

- Acting as a moisture absorption media

- Providing a cushioned resting surface.

Ventilation

Air quality within the microenvironment surrounding the calf must be very similar to the air outside the housing structure. With proper ventilation, the relative humidity will be about the same in the calf zone as it is outside, and the concentration of manure gases, dust, and pathogens is very low. Air exchange is required in order to meet these air quality goals. Air exchange is the process of using outside, fresh air to replace the

mildly contaminated air within the structure. Improper ventilation can cause respiratory problems and reduced feed intake and conversion rates. Recently, a practicing veterinarian returned to her home farm to be the herd replacement manager. She reported that calves raised on their farm in inadequately ventilated facilities did not cope with summer heat stress during ensuing lactations as well as cows raised as calves off the farm in well-ventilated environments.

A shelter should be oriented to take advantage of prevailing winds in the summer and allow sunlight penetration in the winter. Cold drafts from winter winds should be blocked. Orienting a shelter with the open side to the south or southeast is usually the best arrangement in most locations, but truly is site-specific.

Access to Feed and Water

Unrestricted access to feed and water is important to effectively achieve optimal daily weight gains. From a newborn calf’s perspective, feed and water should be:

- Provided individually

- Located outside of the pen to minimize contamination by urine and manure and keep spilled liquid feed and water away from the bedding material.

From a calf caretaker’s standpoint, feed and water should be:

- Easy and convenient to deliver

- Fed from containers that are easy to clean and sanitize.

Housing Alternatives for the Newborn Management Group

Individual Calf Hutches

Individual calf hutches are an excellent housing example for all young stock designs to follow. They meet each calf-housing goal by:

- Allowing separation of a calf from other stock

- Providing good ventilation

- Having a well-defined eating and resting space

- Allowing convenient access to feed and water

- Permitting ease of cleaning and sanitation

- Offering good observation and access potential for the caretaker.

Properly located and maintained hutches work well for calf rearing no matter what your calf management philosophy is. If you are often busy with other activities that won’t allow you to check the calf’s environment many times each day, hutches will be the best option for your farm. Hutches allow the calf to decide where she is most comfortable— in the hutch or in the paddock area.

Like all real world issues, there are advantages and disadvantages with each housing option. We all know the disadvantage with hutches is the varying degrees of discomfort experienced by the calf caretaker. Caretaker comfort can be highly correlated with labor efficiency. Jason Karszes, PRO-DAIRY farm business management specialist with Cornell’s Department of Agriculture, Resources, and Managerial Economics, reports in a study that about 9 calves are cared for per hour when using individual hutches. Providing a roof over the hutches to increase operator comfort is reported to increase the number to 13 calves per hour at an additional cost of almost $600 per hutch.

This data can make it tempting to put caretaker comfort first. Research is being conducted to test the hypothesis that increased caretaker comfort results in a decrease in calf health and an increased calf health care cost due to poorer environmental conditions. Calf ventilation and sanitation should not be sacrificed to provide more caretaker comfort.

Plastic- and Fabric-Covered Arch-Frame Structures

Plastic- and fabric-covered arch-frame structures (commonly referred to as alternative structures or greenhouses) represent the newest trend of housing systems used to raise calves. They are temporary or semi-permanent naturally ventilated structures, which makes them an option to consider for producers looking for a housing system that is easily movable or removable. They can require nearly continuous adjustment of natural ventilation components to provide an acceptable animal environment during many days of the year. This feature makes them more appropriate for farms with designated calf managers or other individuals who spend many hours a day working with the replacement herd and can make the necessary adjustments.

When some of the initial alternative structures first came on the market, several considered them to be miracle structures for raising calves. Producers found them to be initially affordable when compared to other semi-permanent housing options, and they improved the environment for the caretaker. Some manufacturers claimed that the transmission of light through the translucent covering enhanced calf health.

However, producers must not forget the needs of the calves presented above. Economically meeting all calf-housing needs truly defines the proper housing system for you. Alternative structures have some unique characteristics that affect animal needs. Let’s look at two in detail.

Clean, Dry, and Comfortable Resting Area

Provide a clean, dry, and comfortable resting area by ensuring sufficient floor space and drainage for the number of pens required to support the newborn management group. Too many times calf pens are stuck tight against the outside wall where precipitation can fall in the resting area. Select new structures with vertical or nearly vertical sidewalls to minimize runoff from dropping into the shelter. Choose structures with curtain sidewalls that drop down to open. In existing structures with curved sidewalls, move pens away from the sidewalls as shown in Figure 1. Move the pens further inward if blowing precipitation is a problem. Use a well-graded (no fines) stone base to promote drainage.

Adequate Ventilation

Well-managed sidewall, endwall, and peak openings are especially needed to maintain air quality within structures that have transparent or translucent covers. Transmission of radiant energy from the sun through the plastic will quickly warm the air within the structure. The amount of warming is highly dependent on the amount of energy transmitted. Clear plastic coverings transmit about 87 percent of incident light, while white plastic coverings transmit approximately 30 percent. Warmer interior air will result in the following:

- Additional evaporation of free moisture

- Increased production of manure gases

- Increased air moisture from animal respiration.

Without air exchange, much of the moisture evaporated in the day cannot be held in the air when the temperature drops at night. Relative humidity levels increase as the temperature falls, resulting in potentially unhealthy conditions. If conditions are correct, dew-point temperature of the air is reached, and the previously evaporated moisture condenses. Since dew-point temperature is usually first reached along the outer perimeter of housing structures, the condensed moisture falls to the floor, where it can wet the bedding. Without proper ventilation, this cycle can go on for days.

Properly ventilated, well-managed alternative structures can provide adequate housing for dairy replacements if they are well designed and properly managed by meticulous caretakers.

Cost and flexibility also need to be considered.

Costs

When reviewing the cost of purchasing an alternative structure, remember to include both the initial (capital) cost and the projected yearly maintenance and repair costs. Alternative housing structures can be more cost effective initially, but they may end up being more costly over the anticipated life of the structure than a more permanent structure.

Plastic and fabric coatings are subject to damage from the sun, wind, and sliding ice. The reported life expectancy of plastic coverings is four to six years and 15 years for some fabrics. Many times plastic covers don’t last that long due to the lack of back-up power to keep them inflated during utility power outages.

Flexibility

Many different types and styles of alternative housing structures are on the market. Some alternative housing structures are designed to be temporary, while others are meant to be more permanent. Temporary structures can be easily disassembled and moved from one location to another if needed. They are usually held in place by attaching each arched-frame member to the ground with a simple anchoring device. One of the primary reasons to consider this advantage is for disease outbreak. Pen base material that becomes disease contaminated can easily be abandoned by relocating a temporary structure. Disease-laden material needs to be sanitized or excavated from more permanent structures.

Open Front Structures with Individual Pens

Open front structures with individual pens can be either portable or stationary – both are constructed as wood-framed housing units, as shown in Figure 2. Structures should be designed so they can easily be cleaned with a skid-steer loader or small bucket tractor. These structures require less land space than individual calf hutches, and they provide caretaker protection from precipitation and some blowing winter winds. Each individual pen in the shelter is about 3 to 4 feet wide and from 7 to 8 feet deep. In cold weather, a plywood cover can be placed over the rear portion of the pen to minimize drafts and to preserve heat produced by the calf. In warm and hot weather, a removable panel at the rear of the shelter can be opened to provide additional air exchange.

These structures require attention by the caretaker to ensure that the calf environment is maintained properly by adjusting the rear curtain wall. The need for adjustment is not as frequent as with shelters with transparent or translucent coverings. Major adjustments are needed to protect the calf from blowing precipitation and cold winter winds. If you want to provide some degree of caretaker protection over calf hutches but don’t want to be continuously adjusting curtain sidewalls, this structure may fit your management plan.

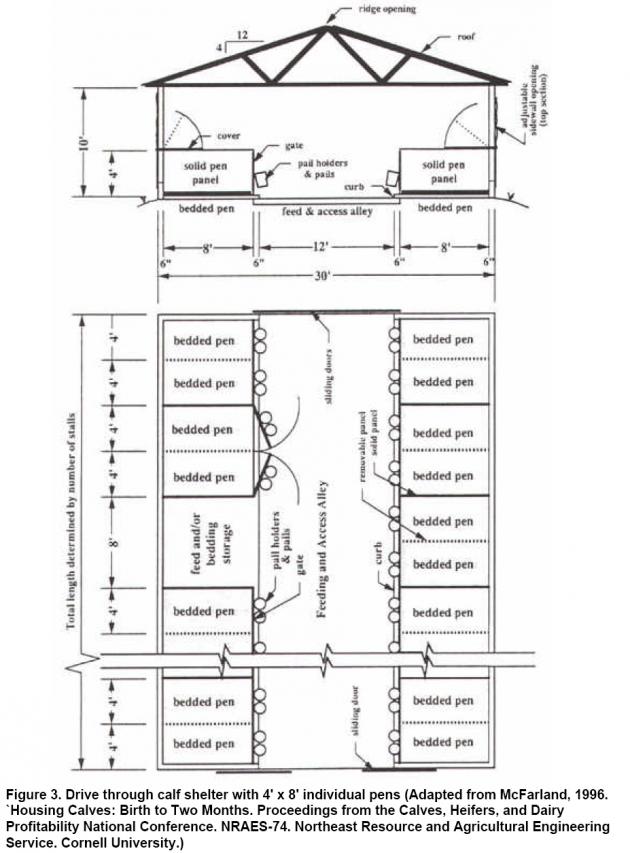

Central Drive-Through Feed Delivery Shelters with Individual Pens

A central drive-through calf shelter is easily created by placing two open front structures facing each other. A gable truss system can also be used to obtain a functional structure as shown in Figure 3. Adequate width of the feed and access alley in this structure is important to ensure sufficient space is available to facilitate bedded pack clean-out.

Ventilation is accomplished by providing the following:

- Adjustable curtain sidewalls, protected from the calves on the inside by using wire hog panels

- An eave with an opening of a minimum of 1” per 10’ of building width

- A ridge with an opening of a minimum of 2” per 10’ of building width.

This type of structure provides the caretaker with as much protection from the elements as an alternative housing structure. Natural ventilation system regulation required for a fixed structure is more than for the open-front structures but less than for the alternative housing structure.

Fixed structures should be given close consideration by producers who:

- Want a permanent structure

- Are willing to implement strict chemical sanitation procedures

- Desire a protected environment for the caretakers

- Prefer to invest more capital per calf pen initially and don’t want to invest much in facility maintenance and repair down the road.

Author Information

Curt A. Gooch, P.E.

Senior Extension Associate

Department of Agricultural and Biological Engineering

Cornell University