Introduction

Calves that have completed the weaning process are ready for their first experience with group housing. The stress associated with being weaned is over, and their immune system is now more developed.

This provides an opportune time to combine calves of similar size and age into small groups to continue their development and increase labor efficiency. Initial grouping of calves begins the socialization process which can cause anxiety, thus resulting in the need for frequent observation. Limited competition at the feeding, watering, and resting areas can occur with appropriately sized groups. Small groups of calves work well from 10 days post-weaning to about 5 to 6 months of age.

Please check this link first if you are interested in organic or specialty dairy production.

This second article in a series on replacement housing systems focuses on the transition management group: calves that are transitioning from individual housing to a group housing system. How you manage the transition management group depends on your overall replacement management plan. Do you have one in place yet? (See Newborn Housing for Dairy Calves.)

Transition calves require the three basic environmental needs we discussed in the first paper: a clean, dry, and comfortable resting area; adequate ventilation; and good access to feed and water. Depending on the size of your replacement herd and other variables—most importantly, site conditions, labor force, sources of bedding material, and manure handling system—an economic solution for transition housing is available to best meet your needs. Two predominant housing options exist which meet all transition calf needs and provide an excellent environment.

Super Hutch

A super hutch is nothing more than a large calf hutch that provides transitional housing for a small group of post-weaned calves. Like calf hutches, these portable open-front structures offer more management flexibility than permanent facilities. Wooden skids are mounted under the structure’s 12’ wide by 19’ long framework, enabling it to be moved between various designated locations to assist with disease control. A hutch of this size has a capacity of 6 to 8 calves weighing up to 400 lb. Multiple hutches are used to handle interval group sizes of 6 to 8 calves. Hutches are used in combination with a pasture or a paved lot where free access to feed and water is available. Contact the Department of Agricultural and Biological Engineering at Penn State University and ask for Idea Plan No. IP 723-37 to get detailed design information and a bill of materials required for fabrication. Their phone number is 814-865-7685.

Modern super hutches have curtain sidewalls to enhance summer ventilation. Careful consideration must be given to protect curtain material and hardware from curious calves. Additional protection can be provided on the outside of the curtain by installing framing material to support protective wire cloth mesh. Or, hutches can be located so calves only have access to the open side of the shelter from the pasture or lot area.

The disadvantages of super hutches are they may require additional restraint and growth monitoring equipment (scales) when compared to a transition shelter. Or, additional traffic lanes are needed to move transition calves from each super hutch to a centrally located restraint and treatment facility. Extra labor may be needed to move animals when a transition group has a large numbers of calves. Ideally, producers with a transition management group of about 18 to 24 animals or fewer should target a super hutch for transitional housing.

Transition Shelter

A transition shelter is a naturally ventilated, three-sided post-frame structure specifically designed for housing the transition management group. In order to economically justify such a structure, a minimum number 18 to 24 calves need to be in this management group.

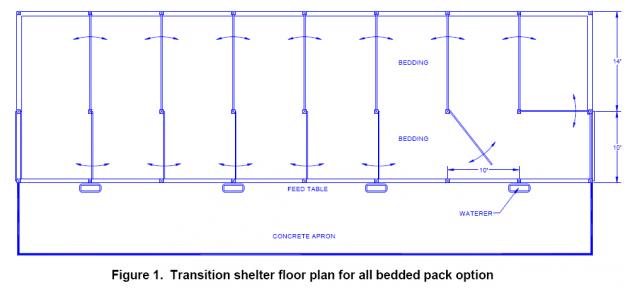

The basic management philosophy of a transition shelter is as follows. A group of 6 to 8 young calves initially entering the transition management group is placed in a 10’ wide by 24’ deep pen located at one end of the shelter. This group is moved to the adjacent pen when the next group of calves is ready to come into the shelter. This process continues until the initial group of calves reaches the other end of the shelter. At that time, they are ready to enter the adolescent management group – at 5 to 6 months weighing up to 400 lb. (The adolescent management group is discussed in the third paper in this series.) The number of pens required in a shelter depends on the number of calves in the transition management group at any one time. Thus, longer shelters can be expected for a larger management group.

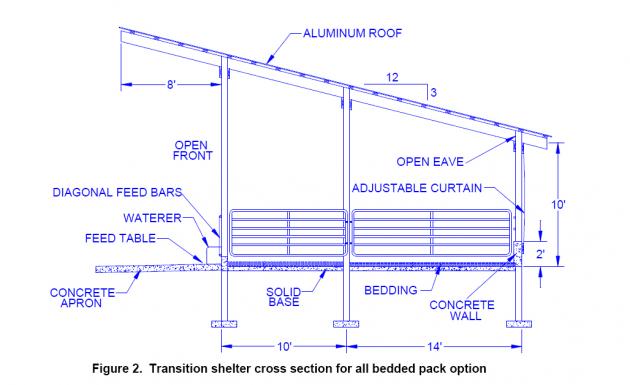

The 10’ wide by 24’ deep pen is sized for either 6 or 8 calves, depending on how it is bedded. If the entire pen is bedded, it can be stocked with 8 calves (see Figures 1 and 2). If part of the pen is bedded and the other is designated as a scrape alley, then the capacity is 6 calves (see Figures 3 and 4). The former option uses more bedding material, but the latter will require regular scraping of the alley.

Transition shelters with a scrape alley benefit from installing a longitudinal curb along the scrap alley/bedded pack interface. This curb makes cleaning of the scrape alley easier, helps to protect the structural post from the scraper blade, and creates a space to store and protect the opened gates during cleaning.

To contain the bedded pack, a 24” high concrete curb is installed along the perimeter of the rear wall and all or a part of the sidewall. The curb should be well constructed to withstand impact loading from a loader bucket during cleanup of the soiled bedded pack. Above the curb on the longitudinal side, curtain walls are recommended to facilitate ventilation. Curtains should drop from the top down in order to prevent drafts on calves during cool periods when less ventilation is needed. Minimum ventilation to control moisture is achieved by air movement through the open front and in the eave space provided between the top of the structural header and the bottom of the roofing material. Doors, removable panels, or curtain material can be used on the gable end walls to promote additional ventilation in the summer. Strategically located endwall

openings allow for easier clean-out of the bedded pack area.

The recommended roofing material is aluminum. When installing aluminum roofing, stainless steel or aluminum screws should be used to avoid dissimilar material problems prevalent with ferric-based fasteners. Aluminum screws are cheaper than stainless steel screws, but they do not work as well when used with purlins constructed from dense wood. The dense wood tends to cause torsional failure in aluminum screws during installation. This results in a hole in the roofing material.

No insulation is required or recommended for transitional calf housing. Insulation is costly and provides no benefit to open-front structures. Excessive radiant heat gain will be avoided with a well-ventilated structure. Consider installing cooling fans in hot climates for use during periods of little natural wind movement.

Swinging gates form the pen partitions. They also are useful in corralling and holding calves in one area of the shelter while the other is cleaned. Gates should be mounted to structural posts in such a manner that when swung fully open they are totally protected by the curb located below (for partially scrapped shelters). Plywood or fabric can be mounted to gates to provide additional protection to the calves from swirling winter winds.

Management flexibility can easily be built into a transition shelter for times of peak usage. Heat stress in dairy cattle routinely causes reduced conception rates, leading to irregular calving intervals. Irregular calving intervals can result in periods when many calves are born within a short time frame. By providing additional pens, these peak periods can be easily handled.

The transition shelter also should have space to store miscellaneous materials that are needed for transition calves. Provide space for scales and an area to restrain and treat calves.

Feed can efficiently be delivered on a feed table located outside of the animal space. Pellet feed and a heifer TMR can all be fed on the feed table as necessary, depending on the age of the calf. Adequate space must be provided for calves to access feed. Allow 18 inches for calves 2 to 4 months old and 15 inches for calves 4 to 6 months old. Diagonal feed rails with a maximum curb height of 10” should be used for calves 2 to 4 months old, while a post-and-rail feed barrier can be used for calves between 4 and 6 months old with a curb height of 14 inches.

The feed table should be smooth to facilitate pushing up feed and feed refusal collection. A smooth surface also enhances cleanliness. Construct the feed table from a high-strength concrete mix in order to resist the acidic conditions present in fermented feeds. Properly installed plastic liners, ceramic tiles, or epoxy coatings embedded in or applied to concrete can also be used as an eating surface with good results. Provide at least a 2% feed table slope away from the feed barrier to provide adequate drainage away from feed.

The preferred location for waterers is one that is easy to access by calves, yet out of the way of daily maintenance activities, and one that will not contaminate feed. Only use frost-free waterers since the air temperature in the shelter will be about the same as the ambient temperature in the winter. Locate the waterer to maximize its investment by providing service to two groups of calves. The height of the waterer should be such that calves can easily obtain water on demand.

Author Information

Curt A. Gooch, P.E.

Senior Extension Associate

Department of Agricultural and Biological Engineering

Cornell University