Contents |

Introduction

It costs a lot more to feed a cow today than it did a year ago. Consequently, increased attention is being paid to the feeding program. One approach to reduce feed expenditures is to decrease the amount of refusals (orts). Nutritional consultants can help feeders to develop programs and routines that result in an accurately prepared ration. This can help to minimize production variation and digestive disturbances and allow a dairy to feed to a smaller refusal rate.

Please check this link first if you are interested in organic or specialty dairy production.

General Considerations

Assuming the TMR costs $0.10 per pound of DM, then each DM percentage point of refusals is potentially worth $0.05 per cow in a herd with a 50 lb DMI. This amounts to $18.25 per ort percentage point per cow per year. If we assume a dairy was discarding its orts, then reducing the ort percentage from 4 to 1% would reduce feed costs by $27,000 in a 500-cow herd with an average DMI of 50 lb. That’s a lot of money. However, if the refusals had previously been properly fed to other animal groups and were displacing an equivalent amount of feed worth $130 per ton of DM, then the producer would need to come up with an additional $18,000 worth of feed (500 cows * 50 lb DMI * 0.03 less ort * 365 days = 137 tons DM) due to the reduction in the amount of refusals. Continuing with this example, if the orts were used in this manner and milk was worth $18/cwt, then the higher refusal rate only needs to generate an additional 0.27 lb/cow/day ($9000/365 days/500 cows/$0.18 per lb of milk) to break even with a 1% ort percentage. If the orts were discarded as opposed to being refed, then the additional 3 percentage points of orts would need to generate an additional 0.8 lb of milk to break even (3 points * $0.05 per point / $0.18 per pound of milk) with the lower refusal rate program.

As will be discussed shortly, the refeeding of orts could cost the dairy money if the practice results in more animals with Johne’s disease, overconditioned heifers, dry cows with excessive energy or an imbalanced mineral program, or reduced intakes in lactating cows. Additionally, a herd averaging 4% orts will have days with 2% and days with 6% orts; both of these scenarios could reduce the actual savings resulting from the refeeding of refusals.

Group management of lactating cows on most freestall dairy farms generally consists of two common approaches: a) fresh and “high” cows, or b) fresh cows, high cows, high heifers, and low or later lactation cows. It can be helpful when considering feeding management to simplistically think of three types of lactating cows: fresh and early lactation animals with increasing intakes that may be fill-limited; peak-intake cows that are often fill-limited; and later lactation cows with slowly decreasing intakes that are eating to meet or exceed their energy requirements.

One basic principle in feed bunk management is that a dairy must have goals for the level of orts or refusals. These goals shouldn’t be the same for each dairy and will vary based on their management philosophies and practices. However, all dairy farms should realize that restricting intake in lactating cows that are trying to increase intakes could limit production. Because of this concern, fresh groups are often fed with the greatest amount of refusals (~ 3 to 5%), while high groups may be fed closer to their actual intakes (1 to 5% orts), and later lactation animals even closer (0.5 to 3%). There is a range around these recommendations because of differences in management (accuracy of forage DM ability to maintain and communicate pen counts, ability to exclude spoiled forages from the TMR, frequency of feed push-ups, etc.) and philosophies across dairy farms.

I am not aware of any research that has evaluated varying levels of orts across lactation to see how production and profitability may be influenced. Friggens et al. (1995) fed 18 mid-lactation Fresian cows in a Latin square design “high” (diets designed to meet maintenance and projected milk yields), “medium” (3.3 lb/day DM less than high), and “low” diets (6.6 lb/day DM less than high). Cows that were fed the high, medium, and low diets produced 35, 32.4, and 29 lb/day of milk, respectively. The study indicates that low-producing cows will produce even less if not allowed to eat to meet their requirements. These results should be considered in herds contemplating feeding to an empty bunk. The goal with low refusal feeding is not to feed to a bunk that has been empty for hours, but rather to one that was “just cleaned up” or has less than 1% refusals.

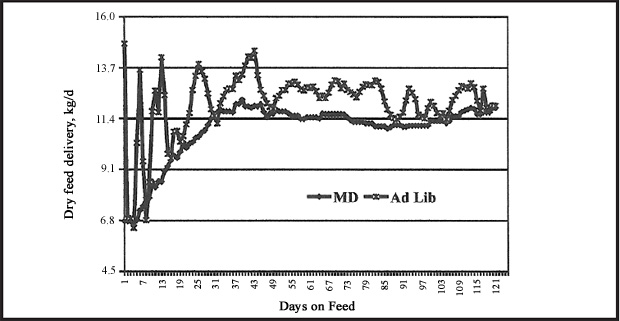

A study was conducted to evaluate feed intake and performance in beef feedlot cattle that were “managed fed” or fed ad libitum (Pritchard and Burns, 2003). The animals on the managed program were fed to achieve their expected maximal feed intake but were not allowed to have periods of higher than expected DMI. Intakes were much more cyclic and variable in the ad libitum pens than in the managed fed animals (Figure 1). Even though the managed fed cattle consumed 12% less feed, they had identical average daily gains. This resulted in a significant improvement in gain:feed ratio in the managed fed cattle.

There are some obvious problems in attempting to transpose these results to the dairy industry. First, dairy animals have much more variation in their nutrient requirements than feedlot cattle that have been grouped by weight and sex. Next, limiting intakes in animals that are trying to increase them in early lactation could reduce production. However, reducing the level of orts could decrease feed costs, result in more stable intakes for the pen, and possibly not result in any loss in performance. If dairy cows behaved like some of the ad libitum fed feedlot cattle, then there could be a reduction in subacute rumen acidosis and indigestion in animals.

Orts – What Should Be Done with Them?

Orts can have a variety of final destinations, and their use influences a herd’s goals for refusal rates. Because of this, refusal usage will be discussed before considering other aspects of bunk management. Orts can be discarded or refed to the heifers, dry cows, low cows, or steers. Let’s briefly consider each approach.

Discarding is the easiest approach since it eliminates any concern about disease transmission, spoilage level, or the effect that the orts may have on the nutrient intakes by the animals receiving them. Additionally, some orts truly should be tossed; they run much more risk of costing the dairy money as opposed to generating any savings from refeeding them. Examples of this type of orts include a refusal that is hot, slimy, and stinky or if the refusal is essentially only sticks, long stalks, and weeds. Herds feeding to a very low (< 0.5 to 1%) refusal rate are more apt to take the discard approach. Of course, discarding orts starts to become prohibitively costly as the refusal percentage increases.

Historically, orts have been fed to the heifers. They are usually a pretty good nutritional match for younger heifers (5 to 10 months), particularly if the ort amount exceeds 3% and sorting has been minimal. The main concern with feeding orts to young heifers is disease transmission, followed by diet variability. I must humbly admit that I had the opportunity to be involved with what we think is the first herd to document that its Johne’s disease was primarily coming from the refeeding of orts to young heifers, and the case deserves some mention, if nothing else for historical reasons. Managers of the herd had been working aggressively with the Johne’s disease control program of Cornell University for many years, yet young cows were still coming down with Johne’s disease. Dr. Chris Rossiter (formerly with Cornell University, now with Poulin Grain) suggested in about 1994 that perhaps the heifers were becoming infected from the cow’s orts. Although the producer and I thought it unlikely, we discontinued the practice of feeding orts to heifers that were entering the lactating herd. Once this change was made, the percentage of animals testing positive for Johne’s took a nosedive among those heifers that had never received cow refusals. The contamination was most likely coming from the cross-over lane in the center of the barn and then being spread along the barn and in the feed by the feed truck and tractor used to push up the feed. The level of Johne’s in a herd, and the ability of management to keep manure out of the orts, should be evaluated when considering the feeding of refusals to heifers. It should only be considered in herds with a very low incidence level of Johne’s, where crossovers are scraped and brushed after cows have returned from the parlor, where only clean equipment is used to handle the orts, and where people do not step in the feed with manure on their boots — and then only to the older (bred) heifer groups. Even then, it should probably be reconsidered.

Orts are often fed to the dry cows or a later lactation cow group. They should never be fed to the prefresh or fresh cows. Orts should be viewed as a ration ingredient and fed at the formulated amount, not at whatever amount is available. It is also a good practice to occasionally submit a multiday ort composite for laboratory analysis. Due to sorting, the ort is almost always wetter, higher in fiber, and lower in protein than the TMR. Another approach to ort management is to have a goal of at least 5% refusal, and then refeed the refusals to all lactating cows except the fresh cows. When using this practice, the orts from each pen should be discarded on a rotating basis once or twice a week to prevent the accumulation of inedible feedstuffs. Feeders need to be evaluating the quality of the refusal with this approach since we do not want the orts to be a yeast and mold inoculant for the rest of the TMR.

Another approach to working with orts is to keep the amount relatively low (< 1.5%) and then feed them to steers. This practice helps to recover some economic value from the orts, it reduces the anguish a producer may feel from discarding the orts, it eliminates all concerns about refusals causing any disease issues in heifers, and it removes the nutrient concerns we may have in the receiving animals. I have seen many groups of steers perform very well with this approach.

Reducing Ration Variability

Feeding for a low rate (< 1%) of refusals necessitates several management practices. The feeder needs to pay careful attention to several factors that will influence the final ration consumed by the cow (Barmore, 2002; Stone, 2003). These factors include the manner in which forages are removed from the silo when preparing a load of feed, forage DM, and the accuracy in which each ingredient is added to the load.

Forages, and haylages in particular, have a large potential for variation. The degree of variation at a given dairy depends largely on its ability to manage the cropping and harvesting systems. One advantage that bunker silos have over upright silos or bags is that ensiled feed from a given load or field is spread over a larger area of the silo. Thus, changes in forage DM or chemical measurements occur more gradually than in other storage systems. However, variation can still occur across the height of a silo. To estimate this potential variation, 11 corn silage and nine haylage bunker silos from nine dairy farms located in central New York were evaluated (Stone et al., 2003). Samples were collected on six dairy farms with a backhoe, on two dairy farms with a loader bucket, and on one dairy with a face shaver. Sample collection was designed to reflect the feed that would be obtained if a feeder obtained a loader bucket of feed from a region (upper, middle, or lower) of the silo as compared to a bucket obtained from the entire height of the silo face. Silos above approximately 12 ft in height (n = 15) were split into thirds for sampling, while those less than approximately 12 ft (n = 4) were split into halves.

The vertical trench was dug to a depth of about 8 to 12 inches. Feed removed from each section was thoroughly mixed and then subsampled to obtain a sample approximately 5 to 10% the size of the removed silage pile. This sample was then again thoroughly mixed and finally subsampled for analysis of DM, ADF, NDF, CP, lactate, and volatile fatty acids (VFA) with wet chemical procedures (Dairy One, Ithaca, NY). The entire approximately 3-liter sample was ground for analytical procedures.

Within each silo, deviations from the minimum analytical result for DM, ADF, NDF, CP, and VFA were determined. Maximum deviations within a given silo were determined by dividing the range by the minimum analyzed value. For example, a silo with measurements of 44.5, 41.2, and 36.6 would have a maximum deviation of 21.6% ((44.5 – 36.6) / 36.6).

Haylage varied more than corn silage (Table 1), although there were examples of extreme variation, particularly in DM, in both crops. In some situations, a feeder could be delivering an entirely different ration from one load of feed to the next if care was not taken in obtaining the forage from the silo. For example, a 54.5% forage ration can range from a 52.8 to a 56.4% forage diet if forage DM was properly obtained (from the entire height or face of the silo) and then the feeder fed by regions. The range would increase to 51 to 59% forage if the sample collected for DM analysis was obtained from one of the regions of the silo (as high as someone could reach, for example) and then the feeder also fed according to regions. Variation like this could result in groups of cows being completely out of feed one day and having a large surplus the next. Dairy feed personnel need to be aware of this variation and of the difference it can make to the final ration delivered to the cow. Techniques to minimize forage variation, such as obtaining each bucket of feed from the height of the silo face or the premixing of forages obtained from across the entire face of the silo, should be part of the standard operating procedures for feeding on dairy farms.

| DM | CP | ADF | NDF | NEL | Lactate | Acetate | Total VFA | ||

|---|---|---|---|---|---|---|---|---|---|

| Haylage | Smallest deviation, % | 5.2 | 3.3 | 1.1 | 5.4 | 1.6 | 5.2 | 25 | 7 |

| Largest deviation, % | 44.7 | 52.1 | 20.0 | 24.8 | 20.0 | 646 | 163 | 287 | |

| Average deviation, % | 21.0 | 17.6 | 10.7 | 14.7 | 9.9 | 112 | 72 | 69 | |

| Median deviation, % | 19.4 | 9.5 | 9.9 | 14.4 | 9.3 | 57 | 50 | 38 | |

| Corn silage | Smallest deviation, % | 1.3 | 2.5 | 2.3 | 0.5 | 1.4 | 3.8 | 11.2 | 0.1 |

| Largest deviation, % | 55.0 | 29.5 | 18.3 | 18.6 | 5.6 | 48.7 | 131 | 41.3 | |

| Average deviation, % | 12.3 | 11.0 | 8.4 | 8.6 | 3.1 | 25.6 | 53.7 | 20.5 | |

| Median deviation, % | 8.3 | 10.0 | 8.6 | 8.4 | 2.8 | 26.0 | 29.9 | 21.4 | |

| 1DM = dry matter, CP = crude protein, ADF = acid detergent fiber, NDF = neutral detergent fiber, NEL = net energy for lactation, and VFA = volatile fatty acids. | |||||||||

Variation within a silo must be considered during the collection of a sample for DM or a more complete analysis. The objective is to collect a sample that accurately represents the silage. Due to the manner in which bunker silos are typically filled, one would expect much more variation from top to bottom than from side to side. Obviously, this would not be the case if it was not filled in even layers across the width of the silo or if water was entering one side of the silo. A representative pile of feed could be obtained with a backhoe or silage defacer by digging a trench near the midsection of the silo or by scraping across the entire face with the loader bucket. A loader bucket does not work as well in digging a “trench” in one area of the silo because it is very difficult to remove a uniform depth across the height of the silo. The large pile of collected feed now needs to be mixed. Although this can be done by hand, the mixer wagon is much easier and is better at breaking up clumps of haylage. However, many mixer wagons will contain a few hundred pounds of residual feed. The contaminating feed can be diluted by adding a loader bucket of the forage to be tested, briefly mixing, and then discharging. The collected forage would then be mixed in the mixer wagon, discharged, subsampled, remixed by hand, and finally sampled using a scooping motion.

Helping the Feeder to Minimize Load Variation

Obviously, the performance of the feeder is an integral component in the accurate preparation of a load of feed. The nutritional consultant, along with the dairy owner or manager, needs to closely work with this individual. The feeder must understand how many seemingly small things can have a huge influence on animal performance. Specifically, they should have an understanding of the following areas:

- Dry matter: what it is, why it is important, and how it should be calculated. Bucholtz (1999) reports that most feeders attending Michigan State University Feeder Schools were uncomfortable with arithmetic and had a poor understanding of the DM concept.

- Face management: methods to keep the silage face straight, with minimal disturbance of packed silage, and minimal amounts of loose feed left at the end of feeding.

- Silage collection for load preparation: silage varies across the vertical face of the silo. Thus, silage used to prepare a load of feed needs to be obtained by uniformly removing silage across the height of the silo.

- Spoiled silage: poor-quality silage that may be located along the top and sides of the silo should be removed so that it does not impair animal performance.

- The potential effect on animal performance of layers of feed within the bunker that are of poor quality.

Load Preparation Considerations:

- Ingredient sequencing: what order works best?

- The importance of accuracy when loading an ingredient into the mixer wagon.

- Mixer operation: when it should be started, length of time and speed that it should run, and minimum and maximum load sizes. Feeders need to be aware that mixer wagons can rapidly reduce ration particle size (Heinrichs et al., 1999).

- Mixer wagon maintenance.

Being a feeder is a difficult, highly important position on a large dairy. Effort should be made to make it easier for a feeder to achieve the results desired of them. Ingredient mixes should be purchased or made on the dairy. This greatly minimizes the number of separate ingredients that must be added to each load and increases the feeder’s speed and accuracy. Load sheets should be printed in a font size that is easy to see and with multiple forage DM increments and animal numbers. Scale displays should be easily visible from the loading tractor and should have a remote that allows the scale to be zeroed after the addition of each ingredient.

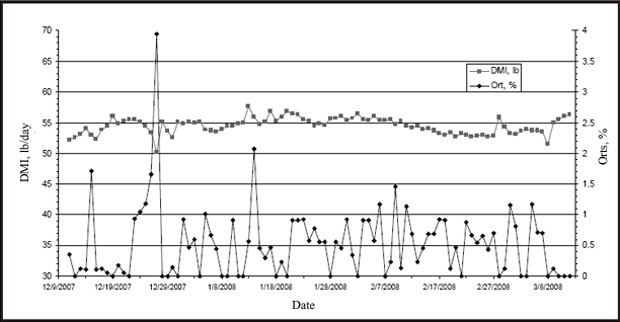

Both dairy farms A and B in Figures 2 and 3 utilize a computerized feed management software system (Feed Watch™, www.vas.com). The program helps them to monitor intakes and make small daily adjustments to keep feed available to the cows (at least on most days) and yet keep refusals to a low level. Other commercially available computerized feed management software systems include: EZfeed™, www.dhiprovo.com; Feed Supervisor®, www.feedsupervisor.com; and TMR Tracker®®, www.digi-star.com (Bucholtz, 2002). The systems can improve a feeder’s accuracy and efficiency both through making their responsibilities easier to accomplish and making the feeder more responsible since (s)he can now be monitored. Dry matters and rations can be updated by the feeder in the bunk or by someone else at the dairy office. The change in ingredient DM is updated in all rations. The systems typically come with a highly visible scale display. The systems can also record the accuracy with which each ingredient was added to a load, the time between ingredients, the time needed to prepare the entire load, and the total mixing time. Providing that cow numbers, DM, and feed drops and orts are correct, an accurate assessment of DM intake can be obtained. Additionally, the software systems help in inventory management and reducing shrink.

Feeding for Low Refusal Rates

Accurate DM is a necessity for dairy farms wanting to operate the bunks at a low rate of refusals. Ideally, a dairy will have multiple Koster testers or vortex dryers and make checking forage DM part of the daily routine. As a minimum, ensiled forages should be tested weekly for DM. More frequent analyses should be run if there is significant variation. The dairy in Figures 2a and 2b runs DM daily on forages removed and mixed with a defacer. The dairy in Figures 3a and 3b runs DM daily on forages that have been premixed prior to feeding. The feeder removes the amount of haylage that will be needed for the day, briefly mixes it in the mixer wagon, and then discharges it near the commodity shed. The same is done for the corn silage. Feeding is then a quicker and more accurate process.

The dairy in Figures 2a and 2b gives bovine somatotrophin (BST) on a 12-day interval. There are proportionately more cows on BST in Figure 2b than in Figure 2a. The BST injection cycle likely accounts for some of the cycling in intakes, although the troughs in DMI do not always correlate with the end of the BST cycle. The dairy in Figures 3 splits the BST injections in each pen, such that half of the eligible animals in each group receive BST on a weekly basis.

The dairy in Figures 2a and 2b has an ort goal of 3%. They adjust the amount of feed fed to a group based on the size of the previous day’s orts to try to stay close to their refusal rate goal. The dairy in Figures 3a and 3b has an ort goal of 0.75% and alters the feeding rate by 0.5 lb DM per cow if the amount of orts is off by more than half of a skid steer bucket (approximately 0.3 lb DM per cow). The low refusal rate at this dairy results in very stable intakes but most probably limits intake in some animals, at least on some days; note how the cows were totally out of feed during the last five days when intakes appeared to be rising (Figures 3a and 3b). This dairy, with the 0.75% refusal goal, has less variation in daily intakes than the dairy feeding for a higher rate of refusals. Indeed, the decreased intake variation in this herd as compared to the higher refusal rate herd bears some similarities to the intake patterns seen in feedlot cattle that are “managed fed” as compared to ad libitum fed (Figure 1; Pritchard and Burns, 2003). Research evaluating the effect of refusal rate on long-term performance of freestall dairy cattle would be of benefit to the industry.

Another key component of successfully feeding for a low refusal rate is that herd managers and feeders must have a good communication system in place so that the feeder is aware of pending changes in pen cow numbers. Also, it’s helpful if cows rarely get mixed up with cows from other pens.

Feed should be pushed up as often as necessary to keep it within easy reach of the cow. Even though this practice may only encourage a small percentage of cows to come to the bunk (DeVries et al., 2003), it does keep feed available and distributed along the length of the bunk. A large refusal rate, 10% for example, is insufficient if cows can’t reach the feed or it is only distributed along a limited length of the bunk.

Using an L. buchneri inoculant at ensiling or a TMR preservative (propionic ± acetic acid and other acids) during warm weather and taking care to exclude spoiled feed from entering the mix will help to successfully feed to a low rate of refusals. Spoiled feed becomes more of an issue when feeding for a low refusal rate; it could make up most or all of the refusals in a herd with poor bunker silo management. Bunker silos should be appropriately managed to minimize the amount of spoilage present, and then feeders need to strive to keep the spoiled feed that is present away from the cows. Harvesting at the appropriate DM, packing to achieve high densities, and properly covering and sealing help to reduce spoilage. Lining the bunker walls with plastic prior to filling and using a plastic that allows less oxygen to pass through it (SiloStop, for example; Bruno Rimini Corp., London, England) will also help to further reduce spoiling.

Conclusions

Nutritional consultants can help feed managers develop habits and routines that result in an accurately prepared ration. Feed managers should realize the importance of properly collecting a forage sample for analysis, have a clear understanding of the DM concept, recognize the benefits of accurately and properly preparing a load of feed, have goals for ort percentages, and a clear program on how the feeding rate should be adjusted based on the amount of refusals and how these refusals should be handled. Proper training in these areas should result in more consistent intakes and production, improved health, and the ability to reduce the rate of refusals.

Author Information

Bill Stone, Ph.D., DVM

Diamond V Mills

References

Barmore, J.A., 2002. Fine-tuning the ration mixing and feeding of high producing herds. Tri-State Dairy Nutrition Conference, Fort Wayne, IN, pp. 103-126. The Ohio State University, Columbus.

Bucholtz, H. 1999. Communicating with the person mixing the feed. Tri-State Dairy Nutrition Conference, Fort Wayne, IN, pp. 204-208. The Ohio State University, Columbus.

Bucholtz, H. 2002. New feed management software. Tri-State Dairy Nutrition Conference, Fort Wayne, IN, pp. 99-101. The Ohio State University, Columbus.

DeVries, T.J., M.A.G. von Keyserlingk, and K.A. Beauchemin. 2003. Short communication: Diurnal feeding pattern of lactating dairy cows. J. Dairy Sci. 86:4079-4082.

Friggens, N., G.C. Emmans, S. Robertson, D.G. Chamberlain, C.T. Whittemore, and J.D. Oldham. 1995. The lactational responses of dairy cows to amount of feed and to the source of carbohydrate energy. J. Dairy Sci. 78:1734-1744.

Heinrichs, A.J., D.R. Buckmaster, and B.P. Lammers. 1999. Processing, mixing, and particle size reduction of forages for dairy cattle. J. Anim. Sci. 77:180-186.

Pritchard, R.H., and K.W. Burns. 2003. Controlling variation in feed intake through bunk management. J. Anim. Sci. 81:E133-138.

Stone, W.C. 2003. Reducing the variation between formulated and consumed rations. Pages 59-66 in Proc. Cornell Nutr. Conf. for Feed Manufacturers. Syracuse, NY.

Stone, W.C., L.E. Chase, and T.L. Batchelder. 2003. Corn silage and haylage variability within bunker silos. J. Dairy Sci. 86 (Suppl. 1):168. (Abstr.)