Contents |

Abstract

Corn distillers grains have become a frequent ingredient of dairy cattle rations. Their high nutrient density and low comparative price make them a feedstuff of choice when formulating least-cost rations. Wet distillers grains (WDG) are the main co-product by volume that remains after fermentation of corn starch to ethanol. Soluble nutrient-rich syrup called “condensed distillers solubles” is separated during the fermentation process which can be sold for feeding purposes as such or added back to the final product to obtain wet distillers grains plus solubles (WDGS). Both WDG and WDGS can be dried at the ethanol plant to yield dried distillers grains (DDG) or dried distillers grains plus solubles (DDGS). Advantages of the dried form are that they are easier to handle, have reduced transportation costs on a dry matter basis, and maintain their quality when stored for a prolonged period of time. An obvious disadvantage of the dried form is the reduction in the energy efficiency of the overall process, as additional energy is needed to dry the wet co-product. In addition, the wet form has been demonstrated to be better utilized as a source of feed by cattle. This has resulted in WDG being considered an attractive feed when the distance between the ethanol plant and the animal feeding operation does not excessively increase transportation costs. Other aspects that need to be considered from economic and practical standpoints are the labor and equipment needed to handle and store WDG. In addition, the pH with which WDG arrives from the ethanol plant is very low due to the addition of sulfuric acid used to halt the fermentation process. This characteristic aids in the preservation of the co-product either when stored alone or blended with other by-products. This paper addresses issues related to the adequate storage of WDG and how they may affect the decision to purchase them.

Please check this link first if you are interested in organic or specialty dairy production.

Introduction

Corn distillers grains are becoming one of the most common feed ingredients in dairy cattle rations. The trend to include distillers grains will depend on the further development of the ethanol industry as well as other biorenewable sources of energy. At the present time, this co-product is sold in either of two forms: DDG and WDG. Wet distillers grains are the main co-product by volume that remains after fermentation of corn starch to ethanol. Nutrient-rich syrup or “solubles fraction” is separated during the fermentation process, which can be sold for feeding purposes or added back to the final product to obtain WDGS. Condensed distillers solubles have an approximate dry matter concentration of 25 to 30%. Both WDG and WDGS can be dried at the ethanol plant to yield DDG or DDGS. In this paper and for the sake of simplicity, we will be using the terms DDG and WDG as synonymous of WDGS and DDGS. What makes DDG a feed in high demand is the fact that they have a high nutrient density, are very palatable, and are usually competitively priced on a nutrient basis. The amount that can be included in a ration is usually limited by the total fat contributed by the rest of the ingredients and the balance of amino acids, particularly for high-producing dairy cows. The amino acid profile in the protein of DDG is fairly similar to that of the original corn grain and, as a result, may be limiting in lysine. What can vary, though, is the degree of protein utilization, as heat applied during the drying process may bind part of the amino acids with sugars in the Maillard reaction, making them unavailable to the animal. Storage and preservation of DDG do not represent a problem as long as they are protected from the weather. Wet distillers grains, on the other hand, are also a good alternative, particularly when the ethanol plant is relatively close to the farm. The advantages of their inclusion are not only determined by their nutrient content and price but also by the rest of the feeds used in the ration. When dry forages and concentrates predominate in the diet, WDG helps “condition” the ration, increasing its palatability and reducing sorting of the feed. On the other hand, if fermented feeds such as corn silage and hay crop silages constitute a major portion of the diet, the inclusion of high levels of WDG result in excessively wet rations and acidic rations that may reduce feed intake.

One thing that further complicates the issue with the use of WDG is that the moisture content of this co-product may vary. Regrettably, WDG oftentimes makes reference to any co-product that is not DDG! In most cases, WDG has a dry matter concentration that ranges between 30 and 40%. When the product dry matter is between 45 and 55%, it is usually called “modified” wet distillers grains. In addition to differences in dry matter content, the nutritive quality of WDG is affected by their processing, handling, and storage. The nutritive value of an otherwise high-quality initial product cannot be expected to be greater than the same product at feed-out time. Inadequate handling and storage conditions can turn an excellent product into a low-quality or even health-compromising feedstuff.

Storage of WDG

Adequate handling and storage of WDG are usually addressed at the farm level. There are nevertheless other critical time-points from processing to delivery which may pose a challenge to their quality. Temporary storage conditions at the ethanol plant can adversely affect the quality of the product delivered to the farm. Platforms where recently produced WDG are temporarily deposited should be kept clean and protected from the weather. This area should be free of rodents, birds, or companion animals as most will readily eat this feedstuff, and their excreta might contaminate the product. All material remaining from previous batches that show mold growth should be removed (as they act as inoculants), and the area should be scraped as clean as possible before a fresh batch is deposited on top. Rained- or snowed-on WDG result in a wetter product, and greater nutrient losses through seepage during transportation and storage occur until finally they are fed to cattle. Seepage from WDG not only results in decreased nutritive value, but it is also an environmental threat due to its high phosphorus concentration and high oxygen demand (high reducing power).

When protected from air infiltration (e.g., in a silo bag), WDG preserves very well either alone or combined with other feeds. Because of its high moisture content, storage is better accomplished in a bunker, covered pile, or silo bag. Regardless of the storage method chosen, the surface needs to be protected from the weather if the truckload is used completely in less than a week. If usage of the shipment will take longer than a week, storage to prevent air infiltration will be required. If these conditions are not met, mold will grow on the surface exposed to the air, resulting in organic matter losses. Mold will grow relatively fast during warm weather, and it is thus generally recommended to use the whole shipment in less than seven days when left in a pile. One of the characteristics of this co-product is the very low pH (3.0 to 4.0) with which it arrives from the ethanol plant (Table 1). This is due to the addition of sulfuric acid to halt the fermentation toward the end of the process. It is this property that aids in the preservation of WDG, provided anaerobic conditions are met.

| Item | Day | SEM1 | ||||

|---|---|---|---|---|---|---|

| 0 | 3 | 7 | 14 | 129 | ||

| pH | 3.1 | 3.1 | 3.2 | 3.2 | 3.1 | 0.04 |

| ———————————– % DM ———————————– | ||||||

| Acetic acid | 0 | 0 | 0.11 | 0.30 | 0.23 | 0.16 |

| Propionic acid | 0.30 | 0.30 | 0.32 | 0.30 | 0.33 | 0.02 |

| Lactic acid | 0.90 | 0.95 | 0.97 | 1.02 | 0.98 | 0.02 |

| 1SEM = Standard error of mean. | ||||||

A simple storage method for WDG at the farm is to have it piled on a firm surface, such as concrete (e.g., bunker silo). This avoids contamination of WDG with soil and also nutrient leaching and percolation into the ground. Once WDG are unloaded, they should be covered with a tarp while not being utilized. The objective is not to create anaerobic conditions but rather to protect them from the rain as this will result in additional runoff, as well as changes in the original moisture content. Even during the winter, covering them is important! Temperature of recently arrived WDG usually exceeds 100°F (commonly over 150°F if fresh from the plant); if they are snowed on, this high temperature will melt the snow, resulting in greater effluent losses. Because of their small particle size and high moisture content, WDG may freeze during the winter, which, in turn, poses another challenge. The advantage of conditioning the rations offered during temperate weather is lost during the winter, but chunks of frozen WDG can challenge adequate mixing and decrease diet consistency.

Another storage method is through ensiling. Ensiling could be done in bunker silos, but silo bags also work well. Although suited for any size of livestock feeding operations, small to medium-sized farms benefit the most from silo bags because they allow for relatively faster removal of material from the exposed surface. Among the advantages of the bags are that they allow for high air exclusion, resulting in low spoilage losses when the product is bagged immediately upon delivery. Due to the high moisture content of WDG, the shape of the bag when observed from either end will resemble a flattened oval. It is important not to overfill the bag, as the pressure that the material exerts on the sides can rip open the bag.

Ensiling WDG with Forages

As previously stated, most WDG have a pH between 3 and 4 upon arrival from the ethanol plant. Initial pH increases when mixing WDG with other feeds and then drops proportionally, depending on the buffering effect and/or original pH of the other feedstuff. This provides an additional advantage in blends which contain 50% or more WDG on a dry matter basis. The pH of most dry feedstuffs is neutral at most; a 50:50 blend with WDG on a dry basis results in a final product with a pH of close to 4. With adequate packing and air exclusion, this acidity is enough for an adequate preservation. Feeds that are ideal to mix are those with a nutrient concentration that complements WDG. Feedstuffs that are low in protein, fat, and phosphorus make for a desirable match because concentration of those nutrients in WDG is high. Examples of such feeds are soybean hulls, beet pulp, citrus pulp, and crop residues, such as corn stalks and small-grain straw. A practical advantage of blending WDG with fibrous residues is that the blend is easier to break during the winter. Research has demonstrated that the dry matter content of those blends should not be greater than 50% to avoid heating. Taking this into consideration, using WDG (60 to 70% moisture) works better than modified wet distillers grains (45 to 55% moisture). This is reason enough to make certain one knows which of the two products is being purchased. Similarly, particle size of the fibrous residue is also critical in order to achieve adequate packing and air exclusion.

When blends of WDG and fibrous residues were stored in silo bags, preservation was adequate for as long as the bag remained closed. One of the difficulties while the bag was being filled was to maintain sufficient pressure in order to minimize bulges and pockets of air in the stored blend. Once the bag was opened, rapid air infiltration resulted in heating, mold growth, and non-enzymatic browning (Maillard). It was concluded that bagging was not the most adequate storage method. There is a recent trend to store WDG/roughage blends in piles rather than bagging them. Although there is a need to conduct more research, results in the field seem to be encouraging. One of the advantages of this latter approach is that packing and air exclusion seem to be easier to accomplish when compared to the material stored in a bag.

Other forages can also be successfully ensiled together with WDG. In a recent trial (Kalscheur et al., 2003), corn silage (CS) and WDG blends were stored in silo bags. Experimental treatments, on an as fed basis, were the following: 1) 100% CS; 2) 75% CS with 25% WDG; 3) 50% CS with 50% WDG; and 4) 100% WDG. Samples were collected from the bag at days 3, 7, 14, and 129 of storage and evaluated for their fermentation characteristics. As it can be suspected, the initial pH was highest for 100% CS, and it decreased (P < 0.05) as the concentration of WDG increased (5.7, 4.6, 4.0, and 3.1 for 100%, 75%, 50%, and 0% CS, respectively). The dry matter concentrations of the straight feedstuffs and their blends prior to ensiling were 27.7, 28.6, 30.0, and 30.8% for 100%, 75%, 50%, and 0% CS, respectively. One point to be noted is that chopped corn plants had even higher moisture content than WDG. By day 3, the pH of the ensiled feeds had dropped below 4.0, with no further decrease over time. It was interesting to note that the pattern of fermentation was not typical of that of normal silage. Lactic acid prior to ensiling was greatest for 100% WDG (0.9% of DM) and decreased as CS concentration increased. One thing to consider is that when corn plants are ensiled, Lactobacillus organisms start to multiply and produce lactic acid until the decrease in the pH inhibits their proliferation. It is very likely that the low initial pH of WDG inhibited the proliferation of homofermentative bacteria, which are responsible for lactic acid production (Woolford, 1984). Acetic acid increased (P < 0.05) from less than 0.01% of DM at day 0 for all treatments to 3.89, 5.67, 4.32, and 0.23% of DM at day 129 as concentration of WDG increased.

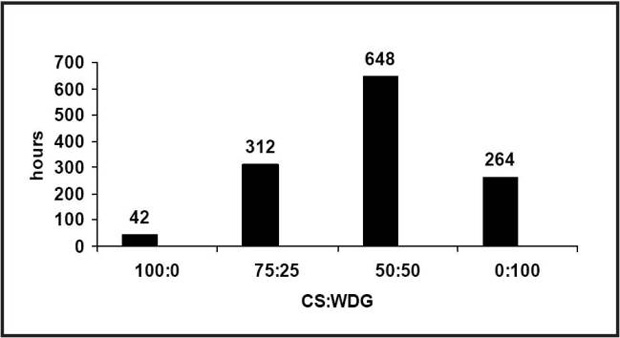

High acetate concentration was probably responsible for the greater aerobic stability observed in the 50:50 blend (Figure 1). Several microorganisms have acetic acid among their end products. Production of acetate in the initial fermentation stages can be due to the activity of heterofermentative bacteria competing with lactobacilli for available fermentable sugars (e.g., from corn plants). The fact that there was very little acetate observed in WDG when ensiled alone can be explained by the relative absence of sugars, which were fermented into ethanol. Under normal fermentation conditions, lactobacilli will take over the fermentation. This would result in increased lactic acid production which drops the pH, inhibiting any further proliferation of this group of bacteria. When the pH of the feed is low from the start (such as with WDG inclusion), homofermentative bacteria are inhibited, allowing for other groups (e.g., heterofermentative bacteria) to proliferate and produce ethanol and acetate. Although there was no ethanol detected prior to ensiling, it increased (P < 0.05) with time in all treatments. Ethanol concentration was highest (2.36% of DM) for 50% WDG on day 129. There was no change in dry matter content, but ammonia-nitrogen increased over time (P < 0.05) in all silages. It is possible that ethanol was produced by the action of heterofermentative type organisms in the presence of available fermentable substrates. It was concluded that ensiling WDG with CS can be used as an effective method of preserving both feeds. The low initial pH that was verified for all treatments, coupled with the high acetic acid concentration during days 3 (2.77%), 7 (3.25%), 14 (3.34), and 129 (4.32), particularly for the 50:50 blend, suggested that preservation could be enhanced by combining both feedstuffs. The blend is easier to handle during the winter when compared to WDG alone, the reason being that longer forage particles allow for easier breaking of the frozen mass.

Aerobic stability of the blends was enhanced when compared to the original feedstuffs, particularly CS. Aerobic stability was measured as the number of hours it took for the temperature in the feed to increase 4°F above ambient temperature (Figure 1). The 50:50 CS:WDG blend had greater aerobic stability upon exposure to air when compared to the other three treatments.

Storing WDG with Soybean Hulls or Wet Beet Pulp

Soybean hulls (SH) are an industry by-product that shows opposite characteristics when compared with WDG as far as their nutrient concentration. This feedstuff is low in protein, fat, sulfur, and phosphorus, which balance very well with the high concentration of these nutrients supplied by WDG. South Dakota State University researchers evaluated the fermentation characteristics of ensiling WDG alone or mixed with SH in laboratory silos (Kalscheur et al., 2002). Treatments were as follows: 100% WDG; 85% WDG:15% SH; and 70% WDG:30% SH (Table 2).

| Item1 | WDG | SH | WDG:SH Blend | Dairy Cow Diet | |

|---|---|---|---|---|---|

| 85:15 | 70:30 | ||||

| DM, % | 32.0 | 91.0 | 40.9 | 49.7 | 50.0 to 60.0 |

| NEL, Mcal/lb DM | 0.91 | 0.75 | 0.86 | 0.82 | 0.76 to 0.82 |

| CP, % of DM | 32.0 | 11.0 | 25.0 | 20.5 | 16.0 to 20.0 |

| Fat, % of DM | 12.0 | 1.10 | 8.36 | 6.01 | 5.0 to 8.0 |

| P, % of DM | 0.70 | 0.21 | 0.54 | 0.43 | 0.38 to 0.42 |

| S, % of DM | 0.33 | 0.09 | 0.25 | 0.20 | 0.18 to 0.22 |

| 1DM = Dry matter, NEL = net energy for lactation, and CP = crude protein. | |||||

Laboratory silos were opened at days 0, 3, 7, and 21 of ensiling, and samples were collected to evaluate the fermentation characteristics of the ensiled feeds. As designed, DM concentration of the ensiled feed increased from 35 to 43 to 49% at 100% WDG, 85% WDG, and 70% WDG, respectively. Crude protein percentage also declined from 30.8 to 21.1 % with the addition of 30% SH. The pH of the 100% WDG was the lowest (P < 0.05) at 3.2 and increased with decreasing levels of WDG (4.0 and 4.3 for 85% and 70% WDG, respectively). Lactic acid was highest for 100% WDG (4.2% of DM) and tended to decline as SH was included in the treatments. Acetic acid, propionic acid, and ammonia-N did not differ across treatments. There was no change in DM, CP, pH, lactic acid, propionic acid, or ammonia-N in the ensiled treatments over time (P > 0.05). Acetic acid increased (P < 0.05) for the 85 and 70% WDG treatment on day 21. Ethanol production increased (P < 0.05) as ensiling length increased. It was concluded that the low pH and the absence of butyrate observed by day 21 resulted in adequate preservation of the blends, even when SH were included at 30%. The production of ethanol and acetate when SH were added to the blends suggests that they supplied fermentation substrates.

Beet pulp (BP) is another excellent feed for ruminants. Although relatively low in protein (approximately 9%), it is a good source of energy due to its highly fermentable fiber and remaining sugars. High concentrations of CP, fat, P, and S present in WDG are matched with low concentrations in wet beet pulp (WBP). Combining both feedstuffs results in blends that are easier to handle when formulating dairy cattle rations (Garcia et al., 2004) and may enhance the fermentation characteristics of the blend once ensiled. The fermentation and preservation characteristics of ensiling WDG with WBP were evaluated in another study conducted at South Dakota State University (Kalscheur et al., 2004). Combinations of WBP and WDG were ensiled in silo bags as follows: 1) 100% WBP, 2) 67% WBP + 33% WDG, 3) 33% WBP + 67% WDG, and 4) 100% WDG; all ratios on an “as fed” basis (Table 3).

| Item | % WDG ensiled in blend | |||

|---|---|---|---|---|

| 100 | 67 | 33 | 0 | |

| DM, % | 33.0 | 30.2 | 26.5 | 23.1 |

| pH | 3.3 | 3.6 | 3.9 | 4.2 |

| ———————————– % of DM ———————————– | ||||

| CP | 30.5 | 25.4 | 18.4 | 8.6 |

| NH3-N | 1.08 | 0.93 | 0.48 | 0.15 |

| Total acids | 6.53 | 4.81 | 2.98 | 2.37 |

| Acetic acid | 0 | 0.40 | 0.55 | 1.06 |

| Propionic acid | 0 | 0 | 0 | 0 |

| Lactic acid | 3.86 | 0.26 | 0.53 | 3.04 |

Samples were collected at days 4, 8, 21, and 112 after ensiling for analysis. The initial pH was greatest for 100% WBP and decreased (P < 0.05) as concentration of WDG increased (4.2, 3.9, 3.6, and 3.3 for 100, 67, 33, and 0% WBP, respectively). Dry matter of the feedstuffs prior to ensiling was 23.1, 26.5, 30.2, and 33.0% for 100%, 67%, 33%, and 0% WBP, respectively. Concentrations of ammonia-nitrogen (0.95, 2.98, 5.83, and 6.75% of DM) and crude protein (8.6, 18.4, 25.4, and 30.5% of DM) increased with increasing concentrations of WDG. Lactic acid prior to ensiling was greatest for 100% WDG (6.41% of DM) and decreased with the inclusion of WBP in the treatments. Acetic acid prior to ensiling was highest (P < 0.05) for 100% WBP (1.06% of DM) and decreased as WDG was included in the treatments. By day 4 the pH of all feeds was below 4.0 and did not change throughout the experiment. Acetic acid increased (P < 0.05) over time in all treatments and was highest for the 100% WBP (5.17% of DM). It was concluded that ensiling WBP and WDG is an effective method of preserving both wet co-products. The low initial pH for all treatments and the increased acetic acid over time suggested that preservation was enhanced by combining both feedstuffs, which reduced fermentation losses. This was corroborated by using ash as a marker to determine organic matter (OM) losses according to the following formula (Garcia et al., 1988):

% OM loss = 1 – A/B*100;

where A = initial ash and B = final ash.

Organic matter loss was 10% or greater for all treatments with the exception of 67% WDG, which was 51.6% lower than for 0% WDG.

Final Recommendations

Agricultural by-products present challenges in diet formulation due to excessive or deficient nutrients compared to nutrient requirements of cattle. Combination of these feeds seems to be a logical approach to improve the efficiency of their utilization in ruminant diets. It is important to consider individual feed characteristics as well as the ease of handling at the farm before choosing a preservation method. The increased demand for ethanol has resulted in increased availability of WDG. The economic and practical feasibilities of transporting and storing WDG on the farm need to be carefully assessed. It has been determined that WDG preserves well when ensiled on its own due to its low initial pH. Similar to other ensiled feeds, their nutritive value can be maintained if air infiltration of the ensiled mass is avoided. Wet distillers grains preserved well when bagged on their own or in combination with soy hulls, beet pulp, or green chopped corn. Among the advantages of the WDG/green chopped corn mix are the improved aerobic stability at feed out as the proportion of WDG in the blend increased and the easier removal of WDG during the winter months. Additional advantages of this approach are to stretch forage supplies during feed shortages, increase the energy density of the diet, and reduce the need for corn grain supplementation.

Author Information

Alvaro Garcia and Kenneth Kalscheur

Dairy Science Department

South Dakota State University

References

Garcia, A.D., K.F. Kalscheur, A.R. Hippen, and D.J. Schingoethe. 2004. Replacement of alfalfa haylage with ensiled wet distillers grains and beet pulp in lactating dairy cows diets. J. Dairy Sci. 87 (Suppl. 1):465. (Abstr.)

Garcia, A.D., W.G. Olson, D.E. Otterby, J.G. Linn, and W.P. Hansen. 1989. Effects of temperature, moisture, and aeration on fermentation of alfalfa silage. J. Dairy Sci. 72:93-103.

Kalscheur, K.F., A.D. Garcia, A.R Hippen, and D.J. Schingoethe. 2002. Ensiling wet corn distillers grains alone or in combination with soyhulls. J. Dairy Sci. 85 (Suppl. 1):234. (Abstr.)

Kalscheur, K.F., A.D. Garcia, A.R. Hippen, and D.J. Schingoethe. 2003. Fermentation characteristics of ensiling wet corn distillers grains in combination with corn silage. J. Dairy Sci. 86 (Suppl. 1):211. (Abstr.)

Kalscheur, K.F., A.D. Garcia, A.R. Hippen, and D.J. Schingoethe. 2004. Fermentation characteristics of ensiling wet corn distillers grains in combination with wet beet pulp. J. Dairy Sci. 87 (Suppl. 1):53. (Abstr.)

Woolford, M.K. 1984. The Silage Fermentation. Microbiological Series, No. 14. Marcel Dekker, New York and Basel.