Introduction

Not all sand is the same. Sand can be obtained from sand pits or mines and is usually referred to as natural sand. Alternatively, sand can come from the processing (crushing) of larger aggregates (rocks) and is called manufactured sand. Some sand is naturally cleaner (low organic matter) than others, some sand has more fine particles than others, natural sand has smoother particles than manufactured sand, and some sand is more uniform in shape than others. When evaluating sand for bedding, we want to look at some of the quantifiable attributes of sand relative to its performance as a stall bedding material.

Please check this link first if you are interested in organic or specialty dairy production.

Positive Aspects of Using Sand as Bedding

From the cows’ perspective, the desirable aspects of a stall resting surface include comfortable to lie on, uniform support, cool in the summer, nonabrasive, and offers confident footing during reclining and rising maneuvers. Producers look for a bedding material that will have a low opportunistic pathogen loading, will drain away moisture and leaked milk, is labor efficient to add and maintain in stalls, and is readily available at a reasonable cost. The use of a 6 to 8” deep bed of loose sand as a freestall or tie stall resting surface meets all of these criteria in many areas of the country. Quality sand is usually available if a ready-mix concrete plant is located nearby.

Desired Characteristics of Bedding Sand

Producers who bed stalls with sand should try to supply stalls with a sand that has the following characteristics:

- Low organic-matter content

- No debris or stones

- Appropriate texture

- Dry material

Quantifying a Sand Material

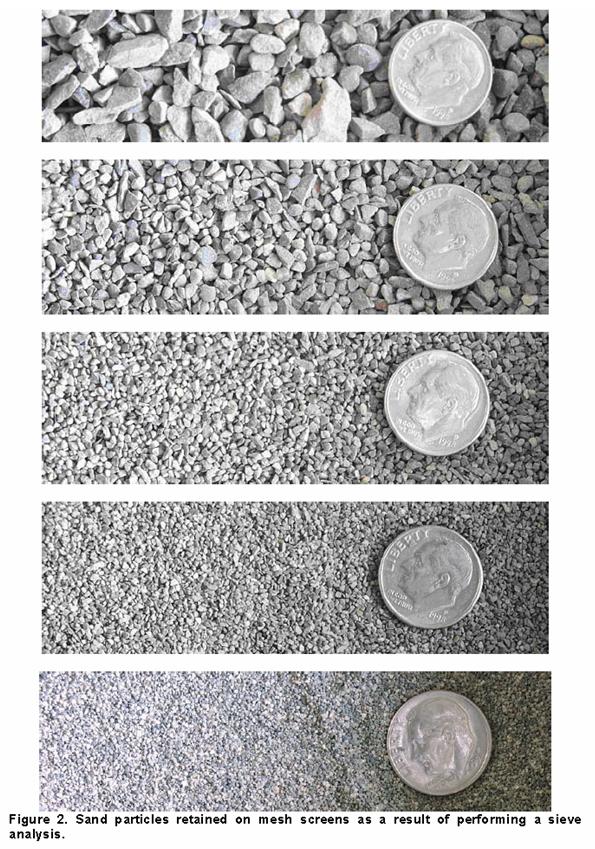

A sand sieve analysis is used to quantify a sand sample by determining its particle size distribution. A stack of successively smaller mesh screens is shown in Figure 1. The size of an individual grain of sand material is usually specified 2 according to the finest mesh that the grain passes through during sieving. Sand particles that have been retained on several successively smaller mesh screens are shown in Figure 2. A logarithmic scale for mesh size (shown along the bottom axis of the graph in Figure 3) provides a clear picture of the sand’s particle size distribution.

Representative particle-size distributions for four sand samples are shown in Figure 3 along with a scale photograph of each sand sample. Samples are: No. 1 – very fine sand, No. 2 – non-certified mason sand, No. 3 – certified mason sand, and No. 4 – certified concrete sand as defined by standards set forth by the American Society of Testing Materials (ASTM). Let’s look at each sand in detail.

No. 1 – Very Fine Sand

This sand was obtained randomly from a freestall barn located in the northeastern United States. Notice that over 90 percent of total particles by weight passed the 0.6 mm screen, indicating the sample has a high percentage of fine sand particles. Also notice that the curve is somewhat less vertical than that representative of sample No. 3. This indicates that the sand is more heterogeneous (doesn’t have a dominant particle size) and tends to be less porous. This sand provides less drainage because there is an ample supply of fine particles to fill voids between larger particles. (In contrast, when sand particles are more similar in size, comparatively large voids exist, forming the pore space that allows drainage of free moisture through the sand layer.) This sand will less readily conform to a cow’s body, is more likely to compact in a stall, has poorer drainage characteristics, and is harder to remove from sandladen dairy manure (SLDM).

No. 2 – Non-Certified Mason Sand

This sand was obtained from a commercial sand mine. A mine representative indicated that this sand is mason sand. A sample was subsequently analyzed by performing a sieve analysis. Notice from Figure 3 that their “mason sand” is very much the same sand as sample No. 1. While a portion of the plot falls within the range specified by the ASTM, as indicated by the blue hatching, overall it is does not qualify as an ASTM mason sand. Using this sand could lead to shortcomings with stall and manure handling expectations. Stall bases may become compacted and sand will be more difficult to separate from manure by either passive or mechanical methods. The results of this analysis emphasize the need to verify the grain size distribution of the sand you intend to purchase to help ensure that it meets your stall bedding expectations and is compatible with your manure handling system.

No. 3 – Certified Mason Sand

Unlike sample No. 2, sample No. 3 was obtained from a supplier that sells a certified product. To become certified, the supplier has to substantiate that they have a product that conforms to specifications outlined by the certifying agency. Notice that the plot for this sample falls entirely within the blue hatched area representing the allowable ASTM plot range for mason sand. This sand has somewhat less fine particles and is more uniformly graded (more homogeneous in nature). It will more readily conform to a cow’s body, will provide better drainage than sand with an increased percentage of fine particles, will compact less in the stalls (thus requiring less stall maintenance), and may result in less sand being transported on cows’ bodies to the milking center.

No. 4 – Certified Concrete Sand

The ASTM range for certified concrete sand is shown in the gray hatched area of Figure 3. To be certified as concrete sand, all sieve analysis plots must fall within this area. Like sample No. 3, this sample was obtained from a certified source and is considered a good material for bedding stalls. It has less fines than mason sand, so it will tend to promote even quicker drainage of liquids, and it will more readily move around under a cow. It is easy to remove from SLDM with mechanical or passive means.

Sand and Hoof Health

Sand bedding cycles through stalls readily, which is a good thing to happen from an udder health perspective. Since cycled sand ends up in the cow alleys in freestall barns, we need to be sure that the sand is not detrimental to the cows’ feet. The maximum particle size that a cow can safely walk on is a function of a sand’s particle size, shape, and hardness. It is also a function of overall foot health as a result of proper trimming and manure removal frequency, quality and quantity of concrete flooring, presence of rubber flooring, nutrition, stocking density, and freestall design (influences time resting). According to Dr. Chuck Guard, Cornell University Veterinary Medicine, sand particle size should not be greater than about 3 mm in most situations. All plots in Figure 3 show that 100 percent of the material passed through a 10 mm sieve but some were retained on the 2.3 mm sieve. Further investigation into how big the maximum particle size is for each sample may need to be performed. This can be done by visually inspecting the larger particles and reviewing the results with a veterinarian or other foot health consultant. Screened sand can be purchased for a bedding material that will not contain sand particles above a screening size.

Where to Obtain Sand

Not all suppliers of aggregates supply sand that is suitable for stall bedding. Care should be taken when purchasing sand to ensure it conforms to expectations. Some suppliers are certified by the state which means that their sand has been tested and found to conform to required specifications. While you may not be building a road or making concrete for a Hudson River bridge, procuring sand from certified sources helps to ensure that you are getting a sand that works for your farm. The New York State Department of Transportation has an approved list of certified sources of fine and coarse aggregates at https://www.dot.ny.gov/divisions/engineering/technical-services/material…, or they can be reached by phone at 518-783-0909.

Non-certified sources can also be viable options to consider. They too can offer suitable sand, but you may need to work with them to determine its applicability. A list of all mining operations in New York State can be found at www.dec.state.ny.us/website/dmn/minedata.htm, or by contacting the Division of Mineral Resources by phone at 518-402-8075.

Similar resources should be available for other states. The National Stone, Sand, and Gravel Association can be helpful. They can be found at www.nssga.org/contact.htm, or by phone at 800-342-1415.

Concerned about Sand Mixed with Manure?

Bedding sand that becomes mixed with manure can easily be handled in an appropriately designed manure handling system. For information on handling sand-laden dairy manure (SLDM), check out the papers listed below available on the PRODAIRY facilities website at www.prodairyfacilities.cornell.edu, or speak with a knowledgeable agricultural engineer.

1. Handling Sand-Laden Dairy Manure from Barn to Storage

2. Effective Means of Handling Sand-Laden Dairy Manure

Freestall and Tiestall Designs for Sand Bedding

Stalls that use sand as a bedding material need to be designed slightly differently than stalls that use mattresses or rubber mats as a stall base material. Why? With mattresses, the 6” wide rear curb is many times included in the resting space provided for the cow. Most mattresses are installed with the rearmost portion of the mattress positioned within 1” of the sidewall of the curb. With sand bedded stalls, the rear curb does not contribute to the resting area so additional space should be provided – typically 72 to 74” measured from the alley side of the rear curb to the brisket board (if utilized). Additionally, the height of the neck rail may need to be positioned toward the lower end of the recommendations (about 44”) since the cycling of bedding sand through the stall will result in this dimension fluctuation somewhat depending on the management protocol for bedding stalls. Complete designs for stalls using various bedding materials are available online at the PRO-DAIRY facilities website.

Summary

The specific gradation of sand used for bedding stalls should be based on maximizing its effectiveness in the stalls and achieving manure handling goals. The use of sand with less fines is preferred from a bedding material perspective. Concrete and mason sands are both examples of sands with fewer fines and are available anywhere ready-mix concrete is sold. These sand gradations can also be separated effectively from SLDM with either confined (mechanical sand manure separation) or special (large basins) sedimentation systems and reused as bedding. Sieve analysis can be obtained from reputable sand suppliers, or you can have an analysis run on a sample of your bedding material by the Cornell Quality Milk Promotion Services. They can be contacted at 607-255-8202.

Author Information

Curt A. Gooch, P.E., Senior Extension Associate

Scott F. Inglis, Research Associate

Biological and Environmental Engineering Department

Cornell University