Introduction

This fact sheet has been developed to support the implementation of the Natural Resources Conservation Service Feed Management 592 Practice Standard. The Feed Management 592 Practice Standard was adopted by NRCS in 2003 as another tool to assist with addressing resource concerns on livestock and poultry operations. Feed management can assist with reducing the import of nutrients to the farm and reduce the excretion of nutrients in manure.

The Natural Resources Conservation Service has adopted a practice standard called Feed Management (592) and is defined as “managing the quantity of available nutrients fed to livestock and poultry for their intended purpose”. The national version of the practice standard can be found in a companion fact sheet entitled “An Introduction to Natural Resources Feed Management Practice Standard 592”. Please check in your own state for a state-specific version of the standard.

The nutrient intake of dairy cattle is limited by the quantity of feed offered, time available for eating, and the digestibility of the feeds. More specifically, the feed offered to lactating dairy cattle is usually heterogeneous in nature, consisting of many different feedstuffs, each possessing unique chemical and physical characteristics. The effects of feeding forages of excessively fine particle size on rumen fermentation and function have long been noted (Cole and Mead, 1943).

Historically, a great deal of research has concentrated on studying the effects of ration particle size. However, these studies estimate particle size according to a variety of methods making practical application of some findings difficult. More recently, a number of experiments have included estimation of ration particle size using the Penn State TMR and Forage Particle Separator (PSPS). Collectively, observations from these studies may be used to build upon our understanding of the effects of a ration particle size and may also be used in the formulation of field recommendations. The purpose of this paper is to detail some of the recent findings that indicate how forage and TMR particle size may affect feeding behavior and rumen fermentation. In addition, this paper outlines how field nutritionists might integrate this information into production based management systems and problem solving methods.

Please check this link first if you are interested in organic or specialty dairy production

Estimating Forage and TMR Particle Size

The PSPS was originally introduced in 1996 (Lammers et al., 1996) and largely because of the simplicity of the procedure, the low cost of analysis and the rapid determination of results, it has become a routinely used device in particle size evaluation. The original device was constructed out of two sieves measuring 19.0 and 8.0-mm and was based on the S424 standard of the American Society of Agricultural Engineers (ASAE). Even though the original apparatus was widely accepted by nutritionists, most of a TMR’s concentrate (typically formulated at 40 to 60%), passed through the 8.0-mm sieve. As a result, an additional sieve containing a pore size of 1.18-mm was developed and is now used to more accurately describe the smaller particle fraction of TMRs (Kononoff et al., 2003a). The pore size for this sieve was selected because it is suggested that 1.18-mm is a critical length governing retention in the reticulo-rumen (Poppi et al., 1985).

Particle Size Recommendations

Although no recommendation may apply adequately to all feeding systems, Table 1 outlines forage and TMR particle size recommendations according to the Penn State Technical Bulletin, DAS 02-42 (2002). When evaluating a TMR, the proportion of material retained on the top screen, or > 19.0-mm, is often considered. This is because the intake of DM from this portion of the diet is known to be positively correlated with ruminating activity and has been demonstrated to be negatively correlated with the amount of time the rumen pH is below 5.8 (Kononoff and Heinrichs 2003a, b; Krause et al., 2002). The current recommendations indicate that the amount of TMR retained on the top screen of the PSPS shown to be 2 – 8 %. This recommendation is based on the collective observations of a series of experiments that evaluated diets within a wide range of particle lengths. The addition of the sieve measuring 1.18-mm allows for a more accurate description of sample fineness, and a more accurate estimate of mean particle length (MPL).

| Type | |||

|---|---|---|---|

| Corn Silage | Haylage | TMR | |

| Sieve Size | %DM retained | ||

| >19.0 mm | 5+/-3 | 15+/-5 | 5+/-3 |

| 19.0-8.0 mm | 55+/-10 | 60+/-15 | 40+/-10 |

| 8.0-1.18 mm | 40+/-10 | 30+/-10 | 40+/-10 |

| <1.18 mm | <5 | <5 | </20 |

| MPL (mm)a,b | 8+/-2 | 10+/-2 | 5+/-2 |

|

aAs estimated by the Penn State Particle Separator (Kononoff et al., 2003a). bMPL = geometric mean length as calculated by the ASAE (2001). |

|||

Forage and TMR Particle Size Effects on Rumen Fermentation

Intake and Rumen Fermentation

The coarse fiber portion of the ration is believed to be effective in stimulating chewing activity and salivary buffer production which, in turn, acts to buffer the rumen and maintain an optimal environment for rumen microbes. Feeding rations low in fiber and of short particle size will decrease chewing activity, salivary buffer secretion, ultimately lowering rumen pH, rumen acetate production and milk fat percentage. Feeding diets low in physically effective fiber may precipitate and contribute to the cascade of factors associated with ruminal acidosis; but the interactive effects of dry matter intake, digestibility, ration nonstructural carbohydrate levels, and feeding behavior should also be considered.

The effect of forage and TMR particle size on feed intake is unclear, with conflicting results often reported. Difficulty in interpreting the response of particle size on DMI may, in part, be due to digestibility and specific gravity- factors independent of the individual feed’s particle size. When detected, intake response to reduce particle size is usually followed by a positive response in intake with the magnitude depending upon the extent of particle size reduction as well as the type and digestibility of the forage fed (Kusmartono et al., 1996).

Rumen pH level is primarily a function of lactic acid and VFA production, which is, in part, buffered by saliva. In one experiment that evaluated the effect of reducing alfalfa haylage particle size, mean rumen pH levels were only moderately affected (6.04 versus 6.15) when the proportion of particles > 19.0-mm was increased from 3 to 12%. Furthermore, diets of shortest particle size were observed to be consumed in the greatest amounts and to have the highest digestibility, resulting in greater rumen VFA concentrations (Kononoff et al., 2002a). The effects of haylage particle size on rumen pH, ammonia concentration, and eating activity is illustrated in Figure 1. In this experiment, there was a quadratic effect observed on rumen pH, with the highest values observed on the intermediate diets. Although rumen pH measurements for the intermediate diets appeared to have similar patterns, the greatest fluctuation was observed in the shortest and longest diets. Possible explanations for this observation may be due to the higher DMI and lower chewing activity, and therefore presumably lower salivary buffer flow, when animals consumed the shortest diet. Figure 1 illustrates higher feeding patterns early in the day, which may have resulted in the marked decrease in rumen pH in animals consuming the longest diet. It is important to note that severe depressions in rumen pH were not observed with any treatment and was likely to be a function of the fact that the rations, on average, contained 31.5% NDF and 42.5% NFC, levels which are similar to NRC (2001) recommendations. In formulating diets, nutritionists should be mindful of these recommendations and it is important to understand that rapidly fermentable carbohydrates may have even greater effects on variation in rumen pH than ration particle size alone (Krause and Combs, 2003).

Applying Estimates of Forage and TMR Particle Size

Harvesting Forages

- Management of TMR particle size begins with harvesting forages at the proper stage of maturity. Because particle size differs little after the forage has fermented, the particle size estimates taken during harvest will likely be the ones used to manage over the next year (Schurman et al., 1995). Differences in forage harvesting machinery design, maintenance, operation, and forage sward characteristics make it impractical to recommend a standard theoretical length of cut (TLC). To ensure that forages meet the recommendations outlined in Table 1, forages should be sampled and tested for particle size during harvest. Once the proper equipment settings have been formulated, it is also recommended that forages be sampled throughout the entire harvesting period. Conducting regular particle size evaluations will ensure that operators maintain sharp knives on harvesting equipment and, because numerous agronomic factors may interact with the harvesting process, it may also indicate that TLC settings require readjustment. The time taken to evaluate particle size may also provide a valuable opportunity to discuss the nature of the chopped material with the equipment operator. While looking at the different fractions retained on each sieve, several items may be considered:

- The number of round cobs retained on the top sieve , as an over abundance may require a finer TLC setting

- The number of hard kernels attached to the cobs, as an over abundance may require a finer TLC setting

- The degree of kernel processing

- The sharpness and precision of cut observed in leaf and stover particles

Feed Mixing

Although harvesting forages at the proper chop length is critical, additional attention should be paid to the process of feed mixing, as it may result in large effects on ration particle size and uniformity (Heinrichs et al., 1999). Producers are faced with several options when choosing a TMR mixer. Generally speaking, TMR mixers can be categorized as vertical or horizontal with different configurations and models within each of these categories. In an evaluation of vertical and horizontal mixing equipment, little difference was observed between the two mixer types. (Rippel et al., 1998). Although some reduction in particle size occurs during mixing, a more important consideration should be the uniformity of the mix. Proper mixing and blending of ingredients requires clear paths of recirculation during the mixing process without the existence of “dead spots.” Although most mixers are designed with this in mind some models are limited in their capacity which may limit the degree of flow that which is needed for proper blending of ingredients (Buckmaster, 1998). When choosing a mixer one should be sure that it delivers a ration of uniform particle size throughout each delivery stage. The PSPS may be used to evaluate mixing uniformity by collecting and analyzing 4-6 samples taken throughout the feed delivery stage. The PSPS may also be used when experimenting and formulating optimal mixing times.

Illustrating Feed Sorting Activity

We have demonstrated that when forage is harvested too coarsely, eating patterns may be affected and this may result in problematic shifts in rumen fermentation. In a study evaluating the effects of corn silage particle size, increasing the proportion of large particles (> 19.0-mm) from 3 to 12% increased chewing activity and rumen pH, possibly due to increased salivary flow. However, increasing the proportion of large particles to 31% resulted in changes in eating behaviors, specifically increased sorting and ultimately, depressions in rumen pH (Kononoff and Heinrichs, 2003a). Nutritionists can evaluate the particle size of the original TMR and compare it to the feed remaining in the bunk at various times during the day and at the end of the 24 hr feeding period to monitor this activity.

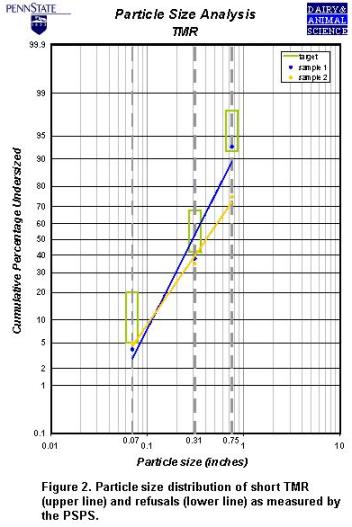

Graphical illustration of particle size estimates attempts to determine the actual frequency of the proportion of individual fractions of the sample. Several mathematical distributions have been employed in interpreting particle size results based on sieving techniques. These include: exponential (Smith et al., 1984), gamma (Allen et al., 1984), and weibull (Lammers et al., 1996) distributions. Finner et al., (1978) described a method of sieving based on a lognormal distribution that has been adopted by the American Society of Engineers for describing forage particle size (ASAE, 2001). Although the best fit of a specific mathematical distribution likely depends upon the methods of sieving, sample type and the nature of processing, the lognormal approach may be the most convenient over others, as others are more mathematically complex due to parameter estimation. Kolmogoroff (1941) was the first to describe a lognormal distribution with respect to ground particles. This approach is simple and results in derivation of two useful parameters; the log mean and log standard deviation that can be used as estimates of the sample geometric mean and standard deviation. A spreadsheet that performs all of these calculations and graphs much of the results can be downloaded from the Penn State Dairy Nutrition website. When plotting the data, sieve size is plotted on the horizontal X-axis, while the cumulative percentage of material that falls below each sieve is entered on the vertical, or Y-axis. Once plotted, a best-fit line can be drawn. For example, in Figure 2 approximately 7% of the feed is more than 19.0-mm (0.75 inches), and as a result, 93% is undersized. In the same sample, 56% of the material is retained on the 8.0-mm sieve (0.31 inches), and a cumulative amount of 37% falls below this sieve. Lastly, 34% is retained on the 1.18-mm sieve and as a result, only 4% is less than 1.18-mm (0.05 inches).

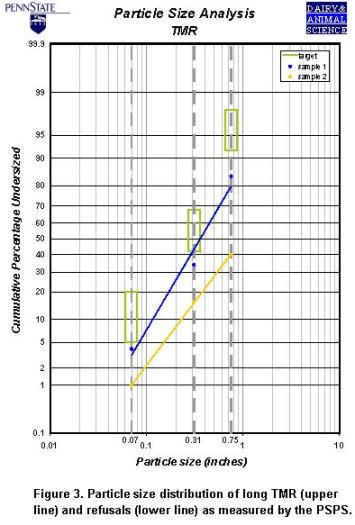

Figures 2 and 3 illustrate the difference in particle size between the originally fed TMR and the refusals. In both figures, the original TMR particle size is plotted with dark points and the best-fit line is drawn in the same shade (upper line). Refusal particle size is plotted with lighter points; and the best-fit line is drawn in the same shade (lower line). Generally, we would desire that each point remain in, or close to, the recommended rectangles and that the associated best-fit lines be close together. When little sorting occurs, such as illustrated in the shorter ration of Figure 2, points falling on the same axis will be close together. In rations that are sorted, such as the longer ration in Figure 3, the lighter refusal line is much lower than that of the original TMR. It is possible to determine if sorting has occurred by comparing the distance between the two points at each particle size (i.e. 1.18, 8.0, 19.0-mm or 0.05, 0.31, and 0.75 inches). In rations that result in a high degree of sorting, a greater spread between points will be observed. More research and field experience will allow nutritionists to make better use of this aspect of the PSPS.

Summary Comments

The PSPS continues to be used as a tool that quantitatively estimates forage and TMR particle size. Reducing forage particle size may increase DMI, digestibility, concentrations of rumen total VFAs, and may also reduce feed bunk sorting behavior of dairy cattle. Rations containing a greater proportion of longer particles (> 19.0-mm) are likely to have a larger difference between the feed originally offered and that consumed throughout the day because of sorting activity. Although chewing activity is closely related to particle size and may have moderate effects on rumen pH (a function of increased salivary flow) other factors such as the amount of fermentable carbohydrates may be more critical when ration NDF levels are near recommended levels.

References

Allen, M.A., J.B. Robertson, and P.J. Van Soest. 1984. A comparison of particle size methodologies and statistical treatments. Pp 36 – 56. in Techniques in particle size analysis of feed and digesta. P.M. Kennedy, Ed. Can. Soc. Anim. Sci. Occ. Publ., Edmonton AB, Canada.

ASAE. 2001. S424. Method of determining and expressing particle size of chopped forage materials by sieving. In Standards. Am. Soc. Agric. Eng., St. Joseph, MI.

Armentano, L. and C. Leonardi. 2003. Problems with sorting in total mixed rations. Pages 87 – 99. Proceedings of The Tri-State Dairy Nutrition Conference. Fort Wayne, IN.

Bal, M.A., R.D. Shaver, A.G. Jirovec, K.J. Shinners, and J.G. Coors. 2000. Crop processing and chop length of corn silage: Effects on intake, digestion, and milk production by dairy cows. J. Dairy Sci. 83: 1264 – 1273.

Buckmaster, D.R. 1998. TMR mixer management. Dairy Feeding Systems: management, components, and nutrients. Proceedings from the dairy feeding systems management, components and nutrients conference. Camp Hill, PA. Pages 109 -110.

Cole, H.H. and S.W. Mead. 1943. A physical deficiency in rations of ruminants. Science 98: 543-544.

DeVries, T.J., M.A.G. von Keyserlingk, D.M. Weary, and K.A. Beauchemin. 2003. Measuring the feeding behavior of lactating dairy cows in early to peak lactation. J. Dairy Sci. 86: 3354-3361.

Dulphy, J.P. and M. Van Os. 1996. Control of voluntary intake of precision-chopped silages by ruminants: a review. Reprod. Nutr. Dev. 36: 113-135.

Ebling, T.L. and L. Kung, Jr. 2004. A comparison of processed conventional corn silage to unprocessed and processed brown midrib corn silage on intake, digestion, and milk production by dairy cows. J. Dairy Sci. 87: 2519-2527.

Finner, M.F., J.E. Hardzinski, and L.L Pagel. 1978. Evaluating particle length of chopped forages. ASAE paper No. 78 – 1047. Am. Soc. Ag. Eng., St. Joseph, MI.

Grant, R.J. 2003. Taking advantage of dairy cow behavior: cost of ignoring time budgets. Cornell Nutrition Conference, Syracuse NY.

Heinrichs, A.J., D.R. Buckmaster, and B.P Lammers. 1999. Processing, mixing, and particle size reduction of forages for dairy cattle. J. Anim. Sci. 77: 180 – 186.

Heinrichs, A.J. and P.J. Kononoff. 2002. Evaluating particle size of forages and TMRs using the new Penn State Forage Particle Separator. Technical Bulletin, College of Agriculture Science, Cooperative Extension. DAS 02-42.

Johnson, L.M., J.H. Harrison, D. Davidson, W.C. Mahanna, and K. Shinners. 2003. Corn silage management: effect of hybrid, chop length, and mechanical processing on digestion and energy content. J. Dairy. Sci. 86: 208-231.

Kolmogoroff, A.N. 1941. About the logarithmic normal law of distribution of particle dimensions generated by disintegration. Proc. Acad. Sci. USSR. 31: 99 – 101.

Kononoff, P.J., A.J. Heinrichs, and D. A Buckmaster. 2003a. Modification of the Penn State forage and TMR separator and the effects of moisture content on its measurements. J. Dairy Sci. 86: 1858 – 1863.

Kononoff, P.J., A.J. Heinrichs, and H.A. Lehman. 2003b. The effect of corn silage particle size on eating behavior, chewing activities, rumen fermentation in lactating dairy cows. J. Dairy Sci. 86: 3343 – 3353.

Kononoff, P.J., and A.J. Heinrichs. 2003a. The effect of decreasing alfalfa haylage particle size on effective fiber values and ruminal fermentation. J. Dairy Sci. 86: 1445 – 1457.

Kononoff, P.J., and A.J. Heinrichs. 2003b. The effect of decreasing corn silage particle size and the inclusion of cottonseed hulls on effective fiber values and ruminal fermentation. J. Dairy Sci. 86: 3343 – 3353.

Krause, K.M., D.K. Combs, and K.A. Beauchemin. 2002. Effects of forage particle size and grain ferment ability in midlactation cows. II. Ruminal pH and chewing activity. J. Dairy Sci. 85: 1947 – 1957.

Krause, K.M. and D.K. Combs. 2003. Effects of forage particle size, forage source, and grain fermentability on performance and ruminal pH in midlactation cows. J. Dairy Sci. 86: 1382-1397.

Kusmartono, A. A. Shimada, K.J. Staffod. 1996. Intra-ruminal particle size reduction in deer fed fresh perennial ryegrass (Lolium perenne) or chicory (Cichorium intybus) . J. Agric. Sci. 127: 525 – 531.

Lammers, B.P., D.R. Buckmaster, and A.J. Heinrichs. 1996. A simplified method for the analysis of particle sizes of forage and total mixed rations. J. Dairy Sci. 79: 922 – 928.

National Research Council (NRC). 2001. Nutrient Requirements of Dairy Cattle. 7th Revised Edition. Natl. Acad. Sci. (Washington DC).

Poppi, D. P., R.E. Hendrickson, and D.J. Minson. 1985. The relative resistance to escape of leaf and stem particles from the rumen of cattle. J. Argric. Sci. 105: 9 – 14.

Ripple, C.M., E.R. Fordan, and S.R. Stokes. 1998. Evaluation of particle size distribution and ration uniformity in total mixed rations fed in Northcentral Texas. Prof. Anim. Sci. 14:44-50.

Schurman, E.W., G.L. Sheppard, and A.J. Heinrichs. 1995. On-farm demonstration of forage particle length of haylage pre and post ensiling. J. Dairy Sci. 78 (Suppl. 1): 200.

Smith, L.W., R.A. Erdman, and E. Russek. 1984. Evaluation of logarithmic normal distribution and four single exponential distributions for describing cell wall particle size. Pp. 83 – 93 in Techniques in particle size analysis of feed and digesta. P.M. Kennedy, Ed. Can. Soc. Anim. Sci. Occ. Publ., Edmonton AB, Canada.

Van Soest, P.J. 1994. Nutritional Ecology of the Ruminant, 2nd Edition. Comstock Publishing Associated, a division of Cornell University Press.

“Extension programs and policies are consistent with federal and state laws and regulations on nondiscrimination regarding race, sex, religion, age, color, creed, national or ethnic origin; physical, mental or sensory disability; marital status, sexual orientation, or status as a Vietnam-era or disabled veteran. Evidence of noncompliance may be reported through your local Extension office.”

Disclaimer

This fact sheet reflects the best available information on the topic as of the publication date. Date 6-20-2007

This Feed Management Education Project was funded by the USDA NRCS CIG program. Additional information can be found at Feed Management Publications.

This project is affiliated with the Livestock and Poultry Environmental Learning Center

Project Information

Detailed information about training and certification in Feed Management can be obtained from Joe Harrison, Project Leader, jhharrison@wsu.edu, or Becca White, Project Manager, rawhite@wsu.edu.

Author Information

P.J. Kononoff

Department of Animal Science

University of Nebraska-Lincoln

A. J. Heinrichs

Department of Dairy and Animal Science

The Pennsylvania State University

Reviewer Information

Dave Christensen – University of Saskachewan

Ian Shivas – Renaissance Nutrition

Partners