Contents |

Introduction

Reducing thermal stress to increase milk production and reproduction during the summer months is a key issue in dairy production. Many studies have documented the negative effects of heat stress (Armstrong, 1994, Collier et al., 1982, Ravagnolo et al., 2000 and Ray et al. 1992). Igono and others (1992) proposed that the Temperature Humidity Index (THI) could be used to evaluate the thermal stress of the environment. This index combines relative humidity and temperature into a single value to estimate the potential environmental heat load. An environment is generally considered stressful for cattle when the THI exceeds 72. Hahn (et al., 1992) showed that feed intake of cattle was reduced when temperatures exceed 75°F.

Lactating dairy cattle produce large amounts of heat due to digestion and metabolic processes, and this heat must be exchanged with the environment to maintain normal body temperature. Cattle exchange heat through the mechanisms of convection, conduction, evaporation, and radiation. Cattle can either give or receive heat energy from the environment. Solar radiation increases heat load by increasing the surface temperature of cattle. Air temperature above the normal body temperature of cattle also increases the heat load. In addition to increasing heat load, heat exchange at the body surface is reduced. Protection from solar radiation by providing adequate shade is the first step in reducing heat stress in dairy cattle.

The effects of heat stress and mechanics of heat exchange were extensively studied at the Missouri experiment station in the 1940s and 1950s (Kibler and Brody, 1949, 1950, 1952, and 1954). Studies showed that at temperatures above 70°F, heat loss was primarily due to moisture evaporation from the skin and lungs. As temperatures exceeded 90°F, more than 85% of the total heat dissipation was due to vaporization of water from the body surface and lungs. Brody and others (1954) suggested that at a temperature of 95°F, wetting the hair and skin greatly increased heat dissipation due to the hair increasing the surface area available for water vaporization.

Please check this link first if you are interested in organic or specialty dairy production

Soaking and Supplemental Airflow

Sprinkling or soaking and supplemental airflow to reduce heat stress has been evaluated in many studies. Researchers in Louisiana conducted several experiments in the late 1940s to determine the effects of sprinkling, shade, and supplemental air movement to cool dairy cows (Seath and Miller 1947 and 1948). They reported that sprinkling cows prior to entering shade reduced respiration rates by 65 to 81% and body temperatures by 46 to 59% over shade alone. They also found that using sprinkling in combination with supplemental airflow resulted in a rapid change in body temperature and respiration rate was superior to either a fan or sprinkling alone.

Wetting frequency and level of supplemental airflow have been shown to have a dramatic impact upon the heat exchange rate of dairy cattle. Hillman and coworkers (2001) showed that increasing airflow and wetting frequency had a dramatic effect on the evaporative heat loss from the skin of dairy cows. Heat loss increased two- to eight-fold when wetting frequency and airflow was increased.

In several studies conducted by Kansas State University (Brouk, et al., 2004a, Brouk, et al., 2004b, Brouk, et al., 2003b), increasing airflow and soaking frequency has reduced respiration rates, body temperature, and body surface temperature of heat stressed dairy cattle. These studies have clearly shown that soaking the hair of cattle once every 5 minutes in association with 6 to 8 mph airflow reduced respiration rates by 50% after one and a half hours of treatment. Both low-pressure and high-pressure systems that soak the skin have been shown to be more effective than high-pressure systems that only reduce air temperature (Brouk, et al., 2004b). These studies have shown that soaking the skin with 0.25 to 0.30 gal of water within 1 to 1.5 min, followed by 3.5 to 4 min of drying time was most effective.

Evaporative Cooling

Soaking and then evaporating water from the surface of cattle represents the most efficient method to remove heat from cattle. However, when environmental temperature exceeds cow body temperature, evaporative cooling of the air may be necessary. Air conditioning would be the most effective by reducing air temperature and relative humidity. However, due to energy cost and system maintenance issues, it is not considered as a practical solution on commercial dairies.

A possible solution is evaporation of water into air as it enters the cow facility. Combinations of tunnel ventilation and evaporative cooling have been used in swine and poultry operations for many years to cool the environment. Recently, these systems have been installed in some Midwest dairy facilities. Huhnke (et al., 2001) reported that evaporative cooling could reduce the total hours of higher levels of THI in some environments. Evaporative cooling has been used very successfully to cool dairy cattle in hot arid climates. Under arid conditions and high environmental temperatures, the potential to reduce temperature and THI is improved. However, as relative humidity increases and or temperature decreases, effectiveness of evaporative cooling to modify the environment decreases. As relative humidity increases above 70%, the potential reduction in THI is less than 10%.

Very few studies have been reported in the literature concerning the effects of evaporative cooling on the stress level of dairy cattle housed in humid environments. Brown and others (1974) evaluated the effects of evaporative cooling in tie-stall housing at Mississippi State University during the summers of 1970, 1971, and 1972. Milk production was significantly increased in one of the three summers, and respiration rates were significantly lowered in two of three summers by evaporative cooling as compared to the controls. The study showed that evaporative cooling could reduce peak daytime temperatures; however, the authors questioned the long-term benefits of the system.

Studies by K-State Dairy Team (Brouk, et al., 2001 and Brouk, et al., 2003a) have indicated that design flaws have resulted in facilities that did not effectively modify the environment. In several cases, facilities that were equipped with modified evaporative cooling systems resulted in higher THI conditions in the barn than outside the facility. Lack of adequate ventilation and efficiency of water evaporation were the primary causes. One limitation of conventionally designed free-stall barns is the large cross-sectional area of the building resulting in greater ventilation rates to maintain airflow at 7 to 8 mph. However, when correct design criteria were followed (Brouk, et al., 2002), tunnel ventilated tie-stall barns equipped with evaporative cooling pads reduced afternoon respiration rates and body temperatures as compared to barns that were only tunnel ventilated. Although afternoon barn temperatures were reduced by up to 8.25ºF, relative humidity increased by up to 30% in the barns equipped with evaporative cooling pads. However, the decrease in temperature was great enough to overcome the increase in the relative humidity resulting in a decrease in THI.

Combining Cooling Systems

Combining evaporative cooling, tunnel ventilation, and skin soaking in high-humidity environments has been the focus of several recent studies. Researchers from K-State and Arizona have evaluated these systems on commercial dairies in Florida and Thailand. In Florida, two 700-ft, four-row dairy barns were equipped with tunnel ventilation with fans on the south end and fully open on the north end. The sidewall height was 11 ft 8 in and the peak height was 13 ft 4 in with a 1/12-pitch roof. Curtain sidewalls were closed during the cooling study. One barn was equipped with a high-pressure fogging system that operated when the temperature exceeded 80ºF from 11 a.m. to 10 p.m. and when above 83ºF from 10 p.m. to 11 a.m. Barn temperatures (Figure 1) were lower and relative humidity higher (Figure 2) during the afternoon hours for the evaporative cooled barn. Similar temperature and relative humidity were observed for the tunnel ventilated barn and ambient conditions. THI was lowered during the afternoon hours with evaporative cooling (Figure 3). In a switchback design, feed line soaking systems were tested in the barn with the evaporative cooling. Eight healthy, high-producing animals were selected from each pen, and a vaginal temperature probe was inserted into each animal. Treatments were: soaking in the afternoon and at night (10 a.m. to 6 a.m. the following morning – afternoon & night) or just at night (10 p.m. to 6 a.m. the following morning – night). The feed line soaking system was activated when the barn temperature exceeded 72ºF and the system soaked for 1.6 min (followed by 4.8 min off). Approximately 0.30 gal of water was applied to the cow’s standing area in each feeding space per soaking. Respiration rates of the cattle fitted with the vaginal probes were observed and recorded at 4 p.m., 10 p.m. and 6 a.m. of each study day. Respiration rates were reduced during the afternoon and at night when cattle were provided feed line soaking in addition to tunnel ventilation and evaporative cooling (Figure 4).

However, morning respiration rates did not differ between the two treatments. The average respiration rates were 8 breaths/min less for the cows soaked both afternoon and night. In areas with high night and early morning relative humidity, evaporative cooling may be effective during the afternoon hours if the humidity drops as ambient temperature increases. Vaginal temperature (Figure 5) was less during the evening hours when cattle were soaked both during the afternoon and at night. The effect of heat buildup during the early evening hours seen in the cattle soaked only at night is a typical response of cattle to an ineffective cooling system. In this situation, ambient relative dropped to just above 70%, allowing an effective evaporative cooling system to lower the temperature almost 10 degrees as compared to ambient. Additional cooling was accomplished with the feed line soakers, and the benefits were greatest when the system operated both day and night.

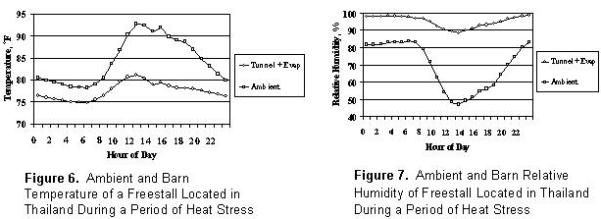

A second study was conducted in Thailand. A two-row, tunnel ventilated free-stall barn equipped with evaporative pads was also fitted with a feed line sprinkling system. The ceiling height of the barn was 8 ft and airflow exceeded 9 mph. The feed line soaking system operated when the barn temperature exceeded 70ºF. When operating, it soaked for 0.5 min and repeated the soaking cycle 4.5 min later. Six healthy cows from each of four pens were fitted with a vaginal temperature recorder. Four cooling treatments were then utilized in a Latin square design to test the effectiveness of feed line soaking in a humid environment. Treatments were control, feed line soaking in the afternoon, feed line soaking at night, or feed line soaking in both the afternoon and night. Treatments rotated from pen to pen each day. The evaporative cooling system effectively lowered barn temperature (Figure 6), raised barn relative humidity (Figure 7), and lowered barn THI (Figure 8).

The relative humidity of the barn generally exceeded 90%. Marked differences in temperature were noted during the afternoon hours. Soaking both in the afternoon and night was more effective in reducing respiration rates than soaking only at night. Soaking in the afternoon was as effective as soaking both afternoon and night in lowering respiration rates (Figure 9). Vaginal temperatures were also maintained at lower level when soaking occurred both during the afternoon and night as compared to control. Data from this study demonstrated the effect of feedline soaking in an extremely high relative humidity situation. Cooling was likely both a function of water evaporation and the temperature of the water applied.

Conclusions

In recent studies, the combination of evaporative cooling, tunnel ventilation, and feed line soaking were more effective in reducing respiration rates and vaginal temperature than tunnel ventilation and evaporative cooling alone. Even in high humidity environments created by the evaporative cooling systems, feed line soaking provided additional cooling for the cattle. The combination of evaporative cooling and feed line soaking is an effective heat stress abatement system.

Considerations in Choosing Cooling Systems

- Shade the cow from solar radiation. This should always be the first step in any cooling system.

- Consider average temperature and relative humidity of location during each hour of the day. Determine when during the day evaporative cooling would be effective. Even in humid environments, afternoon humidity may be low enough to benefit from evaporative cooling.

- If environmental temperature is near or above normal cow body temperature for a significant portion of the summer, some form of evaporative cooling will likely benefit your operation.

- Do not depend upon evaporative cooling alone, except in very arid environments. In most environments, feed line soaking will provide cooling over and above the evaporative system.

- Consider all costs associated with evaporative cooling and feed line soaking. While additional benefits are realized by combination systems, additional milk production may not offset expenses.

References

Armstrong, D.V. 1994. Heat stress interaction with shade and cooling. J. Dairy Sci.77:2044-2050.

Armstrong, D.V., J.F. Smith, M.J. Brouk, V. Wuthironarith and J.P. Harner, 2004. Impact of soaking cows housed in a tunnel ventilated barn equipped with evaporative pads located in Thailand. J. Dairy Sci. 87(Suppl. 1):300-301.

Brouk, M.J., J.F. Smith and J.P. Harner, III. 2002. Effect of utilizing evaporative cooling in tie-stall dairy barns equipped with tunnel ventilation on respiration rates and body temperature of lactating dairy cattle. J. Dairy Sci. 85(Suppl. 1):43.

Brouk, M.J., J.F. Smith and J.P. Harner, III. 2003a. Effectiveness of cow cooling strategies under different environmental conditions. Pages 141-153 in the Proceedings of the 6th Western Dairy Management Conference March 21-14, 2003, Reno, NV.

Brouk, M.J., J.P. Harner, III, J.F. Smith, A.K. Hammond, W.F. Miller and A.F. Park. 2003b. Effect of low-pressure soaking frequency and high-pressure misting on respiration rate, body surface temperature and body temperature of heat stressed dairy cattle. J. Dairy Sci. 86(Suppl. 1):19.

Brouk, M.J., J.P. Harner, III, J.F. Smith, W.F. Miller and B. Cvetkovic. 2004a. Impact of air velocity and direction of flow upon respiration rate, body surface temperature and body temperature of heat stressed dairy catte. J. Dairy Sci. 87(Suppl. 1):300.

Brouk, M.J., J.P. Harner, III, J.F. Smith, W.F. Miller and B. Cvetkovic. 2004b. Response of heat stressed dairy cattle to low-pressure soaking or high-pressure misting heat abatement systems. J. Dairy Sci. 87(Suppl. 1):300.

Brouk, M.J., J.F. Smith and J.P. Harner, III. 2001. Efficiency of modified evaporative cooling in Midwest dairy freestall barns. Pages 412-418 in Livestock and Environment VI: Proceedings of the 6th International Symposium May 21-23, 2001, Louisville, KY. ASAE.

Brown, W.H., J.W. Fuquay, W.H. McGee and S.S. Iyengar. 1974. Evaporative cooling for Mississippi dairy cows. Transactions of the ASAE 17(3):513-515.

Brody, S., A.C. Ragsdale, H.J. Thompson and D.M. Worstell. 1954. Environmental physiology and shelter engineering with special reference to domestic animals. XXV. The effect of wind on milk production, feed and water consumption and body weight in dairy cattle. Missouri Agr Exp Stat Res Bul 545:1-20.

Collier, R.J., D.K. Beede, W.W. Thatcher, L.A. Israel and C.J. Wilcox. 1982. Influences of environment and its modification on dairy animal health and production. J. Dairy Sci. 65:2213-2227.

Hahn, G.L., Y.R. Chen, J.A. Nienaber, R.A. Elgenberg, A.M. Parkhurst. 1992. Characterizing animal stress through fractal analysis of thermoregulatory responses. Thermal Biology, 17(2):115-120.

Hillman, P.E., K.G. Gebremedhin, A. Parkhurst, J. Fquay and S. Willard. 2001. Evaporative and convective cooling of cows in a hot and humid environment. Pages 343-350 in Livestock and Environment VI: Proceedings of the 6th International Symposium May 21-23, 2001, Louisville, KY. ASAE.

Huhnke, R.L., L.C. McCowan, G.M. Meraz, S.L. Harp and M.E. Payton. 2001. Determining the frequency and duration of elevated temperature-humidity index. ASAE Meeting Paper No. 01-4111. St. Joseph, MI. ASAE.

Igono, M.O., G. jotvedt and H.T. Sanford-Crane. 1992. Environmental profile and critical temperature effects on milk production of Holstein cows in desert climate. Int. J. Biometerol. 36:77-87.

Kibler, H.H. and S. Brody. 1949. Environmental physiology with special reference to domestic animals. VII. Influence of temperature, 50° to 5° and 50° to 95° F, on heat production and cardiorespiratory activities of dairy cattle. Missouri Agr Exp Stat Res Bul 450:1-28.

Kibler, H.H. and S. Brody. 1950. Environmental physiology with special reference to domestic animals. X. Influence of temperature, 5° to 95° F, on evaporative cooling from the respiratory and exterior body surfaces of Jersey and Holstein cows. Missouri Agr Exp Sta Res Bul 461:1-19.

Kibler, H.H. and S. Brody. 1952. Environmental physiology with special reference to domestic animals. XIX. Relative efficiency of surface evaporative, respiratory evaporative, and non-evaporative cooling in relation to heat production in Jersey, Holstein, Brown Swiss and Brahman cattle, 5° to 105° F. Missouri Agr Exp Sta Res Bul 497:1-31.

Ravagnolo, O., I. Mistzal and G. Hoogenboom. 2000. Genetic component of heat stress in cattle, development of a heat index function. J. Dairy Sci. 83:2120-2125.

Ray, D.E., T.J. Halback and D.V. Armstrong. 1992. Season and lactation number effects on milk production and reproduction and reproduction of dairy cattle in Arizona. J. Dairy Sci. 75:2976-2983.

Seath, D.M. and G.D. Miller. 1947. Effects of shade and sprinkling with water on summer comfort of Jersey cows. J. Dairy Sci. 30:255-261.

Seath, D.M. and G.D. Miller. 1948. Effect of water sprinkling with and without air movement on cooling dairy cows. J. Dairy Sci. 31:361-366.

Tyson, J.T., R.E. Graves and D.F. McFarland. 1998. Tunnel ventilation for dairy tie stall barns. Northeast Regional Agricultural Engineering Service publication 120.

Author Information

Micheal Brouk

Kansas State University

[mailto: mbrouk@ksu.edu mbrouk@ksu.edu]

Dennis Armstrong, University of Arizona

John Smith, Kansas State University

Matt VanBaale, University of Arizona

David Bray, University of Florida

Joseph Harner III, Kansas State University