Introduction

Mixer design is an art. Field testing, consumer feedback, and experience are used to refine the design. Despite the information collected over years of use in the beef and dairy industries and the yearly design changes, mixer design is still a mechanical art form.

Total mixed rations (TMRs) have become the major feeding system of the dairy industry. Experienced nutritionists and research trials allow us to build better rations. Despite the information collected in research feed trials and the use of ration balancing software, feeding a dairy cow is still a biological art form.

Please check this link first if you are interested in organic or specialty dairy production.

Mixer Design

There are approximately 25 different mixer manufacturers in the market, and, in general, the mixers seem to be doing an adequate job of mixing a TMR. There has been only a handful of cases where the mixer design failed to do the job, and those mixers quickly left the market. In other cases, the mixers were used improperly (over- or under-mixing) which caused nutritional problems for the dairy herds. The mixer design that works best for one farm may not be the best choice for a different farm. The question “Is there a best mixer design?” is open for discussion, debate, and personal opinion. A better question would be “Which mixer is better for my situation?”

There are certainly design differences in the mixers available. Design changes are driven by market and consumer demand. Take for example the consumer demand that a mixer should be able to handle the addition of long dry hay into the ration. This has impacted the design changes of many of the mixers on today’s market. In less than five years. this design goal has produced mixers that can process either a little hay or a lot of hay. This particular design change has caused another potential problem: particle size reduction using too long a mixing time.

Mixer design is still primarily a trial-and-error process with due consideration given to prior experience. The manufacturer selects a specific mixer design that is expected to perform, and field tests determine design changes and their effect on the mix.

In a summary paper on mixer design, these design and testing issues were identified:

- Evaluate mixer design (type, geometry, power, time, speed, efficiency).

- Define material changes (particle size reduction).

- Define standards for comparison of mixers.

- Classify and measure degree of mixing (determine the quality of the mix).

- Describe the mixing process.

- Correlate quality of mix with respect to time.

All of these are good research projects, and some manufacturers and researchers may have answers to some of these problems. Other issues may never be solved. As an industry, there is no effort to coordinate the research efforts or develop standards for testing.

Function of a Mixer

The definition of mixing is the putting together of two or more substances or groups, one with another so that the particles or members of each are diffused among those of the others. The function of the mixer is to blend uniformly particles of different sizes, moisture content, and bulk density. “Perfect” mixing is the state in which any sample removed from the mixture has exactly the same composition. This never really occurs because of segregation due to differences in particle size, density, and shape.

The manufacturers select mixer designs that provide for the needed “degree of mixing” in the desired time. The variation of the mix should be minimal as the feed is delivered out of the mixer. Samples pulled from the beginning, middle, and end of unloading should be the “same.” In reality, this means no significant difference to the animal.

The mixer should allow the use of a variety of feeds to be blended into a ration that provides the desired nutritional requirements for the animal to be fed. The mixed ration should be uniformly blended so that when an animal takes a mouthful of feed, it receives a homogeneous sample of the combined ingredients. The mixed ration should prevent sorting of feeds by the animal and mask less palatable feeds. However, a mixer is limited in its capability to mix a ration by the feed ingredients that are used in the ration.

Mixing requires motion of the particles. This is done by moving particles mechanically with augers, reels, chains, and drums. The mechanical forces that mix the ration can also cause particle size reduction to occur. This particle size reduction may or may not be a beneficial or desired function of the mixing operation. New mixer designs highlighting the ability to mix in dry hay must be able to achieve two opposite goals. On one side, the mixer must be able to cut up or tear apart long dry hay. On the other side, the mixer must not reduce particle size so much that it impacts the roughage value of the ration.

Mixer Design Options

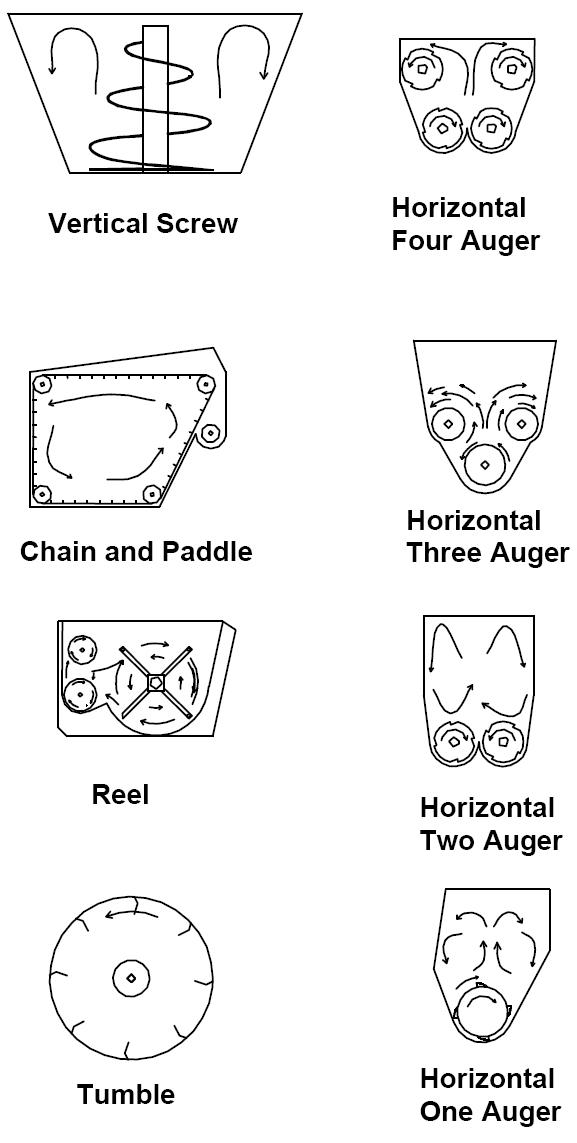

There are approximately 20 different companies producing TMR mixers of various designs. The industry continues to change and adapt to the marketplace. The mixers on the market fall into several general design categories. Figure 1 describes the basic mixer designs. A description of the different trailer mixer designs follows.

Horizontal Auger Mixer

This mixer uses one, two, three, or four augers to churn the feed in a hopper (Figure 1). The feed moves along the flighting of the auger(s). In one- and two-auger mixers, the flighting moves feed toward the middle of the mixer, and it bubbles to the top toward the sides and back down to the augers. Feed is also moved to the discharge door from both ends of the mixer. In three- and four-auger mixers, one or two counterrotating auger(s) and/or flighting moves feed in the opposite direction of the other augers. Feed moves from end to end and from bottom to top. The feed eventually moves toward the discharge door and is unloaded when the door is opened. In many mixer designs, notched auger flighting and/or knife sections attached to the auger flighting provide the ability to cut or tear long hay into 3- to 4-inch pieces and incorporate it into the ration. Design differences in these mixers include rotation speed of the augers, auger diameters, and auger flighting design.

Reel Mixer

This mixer combines a set of augers and a reel similar to a combine reel in a hopper (Figure 1). Feed is lifted and tumbled by the reel moving it to the rotating augers, which provide a mixing action, move feed from end to end and to the discharge door. Knife sections on the auger flights cut or tear long dry hay into 3- to 4-inch pieces and incorporate it into the ration. An optional hay pan allows the hay to be metered into the mixer providing the ability to break up large portions of dry hay or baleage

Tumble Mixer

This mixer is a large drum with spirals and/or pans on the interior circumference of the drum to lift and tumble the ration (Figure 1). A central auger moves feed from end to end and to the discharge door. A large part of the drum opens like a door to allow loading with a Skidsteer or loader bucket.

Chain and Paddle Mixer

This mixer uses a tub or box containing a chain and paddles or slat conveyor to tumble the feed ingredients within the tub end to end (Figure 1). An auger at the front of the mixer provides additional mixing and moves material to the discharge door.

Figure 1. Mixer Design Types

Vertical Screw Mixer

This mixer consists of a large tub with a single vertical tapered screw centered in the tub (Figure 1). A planetary gearbox and transmission drive the screw. Knife sections are attached to the flighting to cut material. Movable shear or restrictor plates on the tub wall provide a shear surface, increasing the ability to process and reduce the particle size of large packages of hay. These units can process rations with almost 100% dry hay. No prior processing of hay is required.

Mixer Cart

Mixing carts are scaled-down versions of some of the designs discussed above. There are chain and paddle, tumble, and reel mixer cart designs on the market. Sizes range from 40 to 80 c.f. They usually are powered by a small 8 to 18 h.p. gas engine. They are used where a smaller volume of feed is needed. The mixing cart can feed approximately 12 to 24 cows per batch mixed. It is a popular option for small herds. Research herds also find them useful for feeding cows on nutritional trials.

Scale

Scales are required on a mixer to properly weigh and blend the ration. Electronic digital readout scales use load cells or weigh bar designs to weigh ingredients in the mixer and are accurate to between 0.25 to 1%. The weighing system is usually supported at three or four places (points) on the mixer chassis depending on the design of the weigh sensors.

Magnet

A magnet attached at the discharge chute is used to pick up hardware before it ends up in the feed bunk. It may be standard or an option on the mixer but should be considered part of a basic mixer system.

Mixer Testing

We don’t have a consumer report of TMR mixing equipment to compare mixers under similar conditions to answer the question “Which mixer gives the best mix?” For an individual farm, the best advice is to have an on-farm demonstration and test the mixer(s) you are considering by mixing a ration that you currently feed. The cow is the ultimate test.

There is no standard method of evaluating a specific mixer design. There is no universally accepted means of comparing mixers or determining what design changes need to be made with a particular mixer to make it “better.” Manufacturers test during the development of a mixer, but, in general, the testing is not consistent from one manufacturer to another or comprehensive to include all mixers.

Ration tests might include using a tracer (salt content), nutritional tests (protein content), and particle size tests (mean particle length). These tests measure the variability/uniformity of the samples. Since a “perfect mix” is impossible, there will likely be some differences in the test results. The test results should be looked at to determine the statistical significance of the variability. A nutritionist, feed consultant, or someone familiar with statistical analysis can help to interpret the test results.

Sampling of the ration can be done at specific times during the mixing process. Always shut off the tractor and/or the mixer before pulling samples from inside the mixer. But most often, sampling is done by pulling samples at the beginning, middle, and end of unloading. Pulling samples along the length of the bunk after the feed is delivered is the most common sampling technique. Samples should be representative of the mix. When pulling a sample, there should be no sifting of the ration. The sample size should be approximately 1 to 2 quarts per sample. Pulling two or more samples at each location, and averaging the results, increases the statistical significance of the results. However, this does increase the cost of tests.

Incorporating Long-Stemmed Forage

Dry baled hay in small or large bales is an example of long-stemmed forage (hay) that some farms like to incorporate into a total mixed ration. First, the hay must be processed, which involves particle size reduction by the mixer if designed to do so or as an additional step before adding to the mixer. “Hay” is generally thought of as alfalfa and/or grass forage. However, the recommendations used by manufacturers are based on the assumption that hay is alfalfa-based forage (possibly with a small amount of grass) which will break up, shatter, or tear up easily. This allows it to be incorporated into the mix easily. Grass-based hay usually causes problems for most mixers because it wraps around augers and is harder to incorporate into the mix.

The amount of hay that can be handled in a mixer is a function of the mixer design. Most of the mixers on the market can handle a small percentage (10 to 20%) by weight or volume of the forage as hay. Several auger mixers and the vertical mixers can handle up to 100% of the forage as hay. Sawtooth augers or knives on the flighting cut or break up the material into small pieces. The longer the mixer is allowed to process the hay, the shorter the length of cut. Usually the hay package is introduced into the mixer and processed for a short time and then additional feeds are added to complete the ration. The vertical mixers can also process wrapped bale silage (baleage). Another way to incorporate hay is to process it through a bale chopper or other type of hay processor.

Batch Mixing

All the mixers on the market are batch mixers. In batch mixing, a ration is followed, and feed ingredients are added one at a time until the required weight of each specific ingredient is reached and the batch is complete. The order of addition of feeds can affect the mixing ability and/or time of mixing. In addition, the loading point of the mixer may affect the time required to get a complete mix. Follow manufacturer’s recommendations on the order in which to add feeds and the recommended mixing time. For example, of 14 mixers surveyed, six recommended dry hay to be processed first, and eight recommended grains to be added first.

Mixing Time

Manufacturer’s recommended mixing times range from 3 to 6 minutes. Depending on the mixer design, processing of large quantities of hay is generally done before adding other feeds and is not part of the mixing time. Small quantities of hay may be adequately mixed during the mixing process depending on manufacturer’s recommendations. Overmixing continues to be a management problem with many TMR rations. In a survey of 49 Wisconsin herds using TMR, the average time mixing was 16 minutes, and the range was 2 to 60 minutes. Additional mixing time past the recommended time only decreases the particle size, usually does not improve the mix, and sometimes causes segregation (separation) of the mix.

Safety

Safety should also be considered in mixer design and use. Metal steps or a ladder should be used to climb up for inspection and allow for safe filling of the mixer. Open-top mixers should have grates in place to prevent accidentally falling into an operating mixer. PTO shields should remain in place. Do not remove safety shields. Never start the mixer before locating children and co-workers at a safe distance. Do not attempt to dislodge wrapped hay from augers or other moving parts of the mixer while it is running. At least one fatality involving a mixer has been documented in Wisconsin.

Total Mixed Ration Volume

Figure 2 shows the approximate volume of feed per cow needed at varying milk production levels. Dry matter intake for varying milk production was obtained from nutritionists. Be aware that these values are estimates from a spreadsheet based on assumptions of a base total mixed ration and densities of feeds used in the rations. Many factors affect the final ration density. The ration densities in this chart vary from 15 to 18 lb/c.f. (as fed.) The ration densities were calculated based on a 70% forage to 30% grain ratio, with haylage and/or corn silage for forage and high-moisture ear corn as the grain. Four different rations are shown. As-fed bulk densities of the feeds were assumed to be 12 lb/c.f. for hay silage, 14 lb/c.f. for corn silage, 46 lb/c.f. for high-moisture ear corn, and 5 lb/c.f. for dry hay.

Figure 2. TMR Volume per Cow (As Fed)

The resulting TMR ration volume estimates from the spreadsheet have been checked with several manufacturer’s recommendations and seem to be close to what salespeople suggest for sizing a mixer.

There is a difference in ration density when substituting some dry hay for haylage. The addition of dry hay tends to bulk up the ration. The as-fed ration density decreased approximately 1 lb/c.f. for every 10% addition of dry hay for silage. As the TMR ration density decreases, the ration volume per cow increases, requiring a larger mixing capacity. A ration with 20% replacement of dry hay for silage is also shown. Substitution of dry hay above 20% of the ration will probably decrease the ration density as well, but it is unknown how much it will affect the density.

In one ration, corn silage was substituted for some haylage. Since corn silage tends to have a slightly higher bulk density than haylage, the as-fed ration density increased approximately 1 lb/c.f. As the TMR ration density increases, the ration volume per cow decreases, requiring a smaller mixing capacity. The volume read from the chart for a particular ration can be used to determine the mixing capacity needed for a group of cows.

Mixer Sizing

The mixer size depends on the group size, ration density, production level, and the number of times each group is fed. For example, using Figure 2, with a ration that has 10% dry hay, the ration density is approximately 16 lb/c.f. A cow producing 80 pounds of milk per day requires a ration volume of approximately 6.5 c.f./cow/day.

A group of 100 cows at this production level would require:

100 cows x 6.5 c.f./cow/day = 650 c.f./day

Feeding twice a day would require:

650 c.f./day / 2 times feeding = 325 c.f. mixing capacity

This is the mixing capacity per batch of feed for this group of cows. Some farms considering feeding only once a day during some parts of the year would mean either buying a mixer large enough (650 c.f.) for once-a-day feeding or mixing two batches (325 c.f.) each. Economics, labor availability, and feed management will help determine the decision.

The struck or level capacity of a mixer is the total volume of the mixing compartment. Mixers are rated from 60 to 90% of the struck level capacity of the mixer depending on the manufacturer. A good estimate would be to buy a mixer based on 60 to 70% of the struck level capacity of the mixer or asking for the mixing capacity of the mixer. Always follow manufacturer’s recommendations on mixer capacity. Overloading mixers beyond their rated mixing capacity increases the mixing time required for a uniform mix and may result in spillage and lost feed.

Mixer Costs

A survey was done to determine costs of mixers on the market in 1998. The cost data represent the manufacturer’s suggested retail price (MSRP) of their line of mixers. Features included in the MSRP were a trailer-mount mixer, with medium-priced electronic scale, and magnet on the discharge, ready for use. The information includes 59 mixers representing 11 companies. Most companies have from four to eight mixer sizes in their line. The costs of the mixers ranging in size from 120 c.f. to 900 c.f. were plotted in Figure 3. No comparison between companies was done. The cost data were plotted according to stated mixing capacity of each model mixer and the quoted price. This information is useful in developing enterprise budgets.

Figure 3. TMR Mixer Costs

Selecting a Mixer

With so many mixers on the market, the selection of a mixer becomes a matter of being a good consumer. This requires that buyers determine their needs, match mixer features to those needs, and research the different mixers available. The questions below need to be answered and should lead you to select the correct mixer for your situation. The answer to the question “Which is the best mixer?” will have a different answer for you and your neighbor.

- What size mixer is needed?

- What kinds of feeds are in my ration?

- Can this mixer blend my ration?

- Can this mixer incorporate the amount of dry hay needed in the ration?

- Will the mixer provide a uniform mix (with my ration)?

- How many hours per day will the mixer be used?

- Is there local service?

- Is the mixer well built?

- Is the mixer available on a trailer or truck mount?

- What kind of scale is available?

- Are there other mixers of this brand around that I can inspect?

- What other options are needed?

- What is my budget?

Author Information

David W. Kammel, Professor, Biological Systems Engineering Department, University of Wisconsin-Madison

References

ASAE Standard: ASAE S424. ASAE, St. Joseph, MI.

Buckmaster, D.R., L.D. Muller. 1992. How do we characterize an adequate TMR mix? ASAE paper 92-1542. 1992 ASAE Winter Meeting. Nashville, TN.

Lindley, J.A. 1991. Mixing processes for agricultural and food materials. Journal of Agricultural Engineering Research 48:153-170.

Lundmark, B.A., D.R. Buckmaster. 1995. Effect of mixing time on TMR particle size. 1995 American Forage and Grassland Conference Proceedings. pp. 214-218.

Possin, I.R., C. DeCorte, R. D. Shaver, R.T Schuler. 1994. Survey of particle length and metabolic disorders on commercial dairies. Dairy Science Department, UW-Madison. Shaver, Randy D. 1990. Forage Particle Length in Dairy Rations. Dairy Feeding Systems Symposium. pp. 58-64. Northeast Regional Agricultural Engineering Service, Ithaca, NY.

Shinners, K., D.W. Kammel, R.D. Shaver, G. Oetzel. 1994. Characterizing and Quantifying Adequacy of Total Mixed Rations: Engineering and Animal Focus. Research Proposal.

Wilcox, R.A., D.L Unruh. 1986. Feed Mixing Times and Feed Mixers. Cooperative Extension Service, Kansas State University.