The most important factors that determine the selection of the type of housing for dairy cattle are cost, animal comfort, worker’s efficiency, durability, and a favorable return on investment. Since the first low-profile cross-ventilated (LPCV) barn started to operate in South Dakota in the fall of 2005, at least six more facilities have been built in that state using this technology, and dozens of them have been built in the rest of the country. Although LPCV barns (enclosed, year-round controlled environment) are a new concept in the dairy industry, housing systems similar to LPCV barns have been used for a long time in the swine and poultry industries. In the United States, the number of dairy farms with more than 500 cows has increased in the last decade by more than 21%, from 2,795 dairies in 2001 to 3,400 in 2010. This new facility design would be suitable for these larger dairy operations.

Please check this link first if you are interested in organic or specialty dairy production.

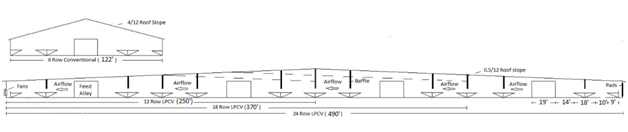

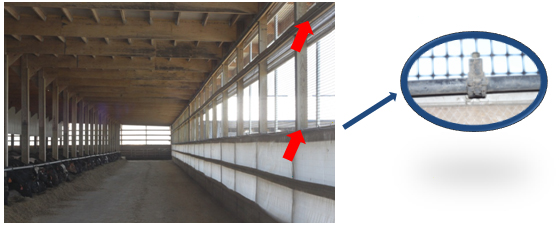

One peculiarity of this design is that it merges conventional barns (4 or 6 rows of freestalls) under the same roof, eliminating the space required to separate each barn. For example, when two traditional barns of 4 rows are merged, a new LPCV housing with 8 rows is developed (Figure 1). The interior of the building is similar to the conventional barns. The main difference is the presence of baffles that hang approximately half-way from the ceiling and are attached to the barn columns (Picture 1). The function of these baffles is to increase the air velocity and redirect air toward the freestalls. To reduce the height in the center of the barn, the slope of the roof changes from a 4:12 pitch in conventional barns to a 0.5:12 pitch in LPCV barns. The height of the side walls is identical in both types of facilities (minimum 12 feet), but because there is less roof slope, the height at the center of the barn is lower in the LPCV barn; thus, the name low-profile. On one of the side walls, there are exhaust fans (Pictures 2 and 3) and on the opposite side, there is the air intake (made of evaporative panels in some cases; Picture 4); thus, the name cross-ventilated. The access doors to the alleys are situated on the front end, similar to conventional barns (Picture 5).

Figure 1. Example of a 667-foot long LPCV barn, with front doors to access each alley and a central alley that connects the pens with the parlor.

Picture 1. Metal baffles placed in between two rows of freestalls.

Picture 2. Interior view of the side wall made up of fans.

Picture 3. Exterior view of the side wall made up of fans.

Picture 4. Interior view of the side wall with the air intake made of evaporative panels.

Picture 5. Front view of an 18-row LPCV barn.

Dimensions

The width required for a conventional barn of 4 rows (103 feet) can be observed on the top of Figure 2, with head-to-head freestalls and a central feeding alley. By merging two, three, or four barns of this type, an LPCV barn is formed of 8, 12, or 16 rows with widths of 213, 317, and 420 feet, respectively (bottom of Figure 2). Figure 3 shows a conventional barn with 6 rows (120 feet). A frontal section of LPCV barns can be observed on the bottom of Figure 3 of 12 (250 feet), 18 (370 feet), and 24 (490 feet) rows, obtained by merging two, three, or four conventional barns of 6 rows. The LPCV housing requires approximately 3-foot wide alleys along the lateral walls to allow for access to the fans and evaporative panels and to perform maintenance. The examples in Figures 2 and 3 have been designed with identical alleys and freestall dimensions. The freestalls have a length of 9 feet, the feed lanes are 19 feet wide, and the pen feed and back alleys are 14 and 10 feet, respectively. The design and dimensions described in this article are just an example of an LPCV barn, but there can be variations. For example, two rows of freestalls can be separated and placed head-to-head to form two independent rows tail-to-tail. Another variation would be to have a feed lane along the lateral walls and in this case, it would not be necessary to have an access alley to the fans and evaporative panels (Pictures 2 and 6).

Figure 2. Top: Front view of a conventional barn with 4 rows of freestalls. Bottom: Front view of an LPCV barn with 8, 12, or 24 rows.

Figure 3. Top: Front view of a conventional barn with 6 rows of freestalls. Bottom: Front view of an LPCV barn with 12, 18, or 24 rows.

Picture 6. Interior view of the side wall with 2 rows of nozzles (red arrows).

The main disadvantage of 6-row barns compared to 4-row barns is an approximately 40% reduction in feeding space (3 rows of freestalls per feedbunk). This can result in a reduction of optimum feed intakes and can negatively impact milk production. In addition, the alley area available to each cow decreases in similar proportion, which results in overcrowding. Due to the lower investment per cow housed, barns with 6 rows are highly used, particularly in larger dairies. If the width of the 4-row barn is increased by 17%, the number of freestalls increases almost by 40%, when there are 6 instead of 4 rows. In addition, increasing to 6-row barns results in a 37% reduction in natural ventilation (Chastain, 2006), which might become a problem on hot summer days.

Variations in dimensions and housing capacity can be seen in Table 1. In barns with a length of 667 feet, the number of rows of freestalls increases from 4 in conventional to 24 in LPCV barns. The width of the alleys and length of the freestalls are identical to those in Figures 1, 2, and 3. Due to their extreme length, the building is divided in the middle by a 33-foot wide central alley that connects the pens with the milking parlor and allows access for cleaning and bedding equipment. There are then 317-foot long pens on each side of the central alley. Each pen has four cross alleys connecting the feed alley with the back alley. In these cross alleys, there are 15 feet long for locating the waterers. The side alleys that are situated along the lines of fans and evaporative panels are 3 feet wide. The width of the freestalls is 4.1 feet, ideal for cows’ 1,400 to 1,500 pounds of body weight. The bunk space per cow is 2.6 feet with pens that have 2 rows of freestalls and 1.6 feet for pens with 3 rows. The alley area per cow goes from 63.4 square feet in pens with 2 rows to 38.8 square feet in pens with 3 rows. The number of freestalls in each pen is 120 for pens with 2 rows and 196 for pens with 3 rows. The housing capacity increases by 480 freestalls in 4-row conventional barns and up to 3,136 in LPCV barns with 24 rows (3 rows per pen).

Table 1. Dimensions (feet) and housing capacity of different barn types with a total length of 660 feet.

One of the advantages of the LPCV system compared to the conventional system is less space requirement (smaller footprint). To facilitate natural ventilation, conventional barns need to be separated from other buildings at least 100 feet or 1.5 times the width of the barn (Brouk et al., 2001). The surface area needed to build a 16-row LPCV barn such as in Table 1 is 280,140 square feet. However, the area required to build four conventional barns of 4 rows each is 474,904 square feet. Although both examples have 1,920 freestalls, the area required increases by 72% in the conventional system. The area needed per cow goes from 146 square feet in a 16-row LPCV barn to 247 in a 4-row conventional barn. This is one point to consider due to the increase in agricultural land prices during the last few years. In addition, this smaller building footprint reduces the distance that cows need to travel from the pens to the milking parlor. Cows that walk less have more time for other activities such as eating or resting. These benefits increase as milking frequency is increased.

There are several options in the number of doors needed to allow equipment access to the cow alleys. One of them is to place a door in each alley (Picture 5). The other option is to place doors exclusively in the feeding lanes (Picture 7) and access pen alleys from the central alley that connects the pens with the milking parlor. The width of this alley depends on the maneuvering space required for each type of machine. With this design, the number of doors in a 24-row LPCV barn may be reduced from 20 to 4.

Picture 7. Front view of a 24-row LPCV barn.

Ventilation

The ventilation system consists of exhaust fans, baffles, and air inlets. In contrast with conventional systems in which mechanical ventilation is used exclusively during hot weather, in LPCV systems, ventilation needs to work 24/7 year round. Therefore, backup generators and alarm systems are required additions.

The fans refresh the air inside the barns with outside air to reduce the indoor concentration of gases and heat. One of the advantages of LPCV barns is the possibility to maintain constant air velocity year round. The performance of the fans depends on their diameter, number of blades, operational speed, and potency of the motor. The suggested fan dimensions are between 4 and 6 feet in diameter. They are placed on the opposite wall of the barn to the evaporative panels that form the air inlets along the side wall. One advantage of the LPCV is that the flow of air is across the barn, parallel to the freestalls, and can thus flow in between cows that are lying down. It is not necessary or desirable for all fans to be working during the colder months, but it is still important to run some fans to reduce the concentration of gases inside. Some farms control their ventilation system according to the concentration of ammonia in the barn. At lower ambient temperatures, the opening of the air inlet can be reduced to avoid freezing of the manure.

The baffles are placed longitudinally on the interior columns (Pictures 1 and 7). Their function is to increase the air speed in the freestall area from 3 to 4.4 feet/second up to 8.8 to 11.7 feet/second (Harner and Smith, 2008). In addition, they redirect the air toward the area of the freestalls. The bottom of the baffles is located at least 6 feet from the floor, and it continues uninterrupted toward the ceiling. Therefore, the baffles do not interfere with the movement of the animals. Baffles can be constructed with rigid (generally metal) or flexible (similar to tarp) materials.

The air inlets can consist of evaporative panels. These panels are made of cellulosic fiber with channels that allow the air to be humidified as it passes through the openings. Water circulates over the pad as air is drawn through it, and all excess water is re-circulated in the system. The air temperature decreases as moisture increases, which results in the lowest air temperature when air is 100% saturated with water. This is not the usual situation, as maximum saturation efficiency is 85% in most evaporation panels. On the other hand, high relative humidity is not recommended for adequate animal comfort. The saturation efficiency of the panels depends on the air speed that goes through them. At lower speeds, the air has more time to incorporate moisture, and thus the efficiency increases. To obtain saturation efficiencies of 70% and 80%, air speeds of 6.7 and 3.3 feet/second are needed, respectively. Due to the quality/price relationship, 6-inch thick panels are utilized more frequently in cattle housing. Water is added to the evaporative panels only during the warmer months when animal cooling is desired.

Some dairies have opted to substitute the evaporative panels with high-pressure water spray systems. These are placed on the side wall where the air intake is located and send water droplets through aspersion. Several rows of nozzles are needed to ensure homogeneous air saturation (Picture 6). The advantage of this system is that it allows more natural light to enter the barn. For optimum performance, both cooling systems need periodic maintenance and soft water with low mineral content.

Other Considerations

An important consideration with LPCV barns is to have an adequate artificial lighting system due to the fact that the building is completely enclosed. The recommendation for lactating dairy cows is 16 to 18 hours of continuous light each day, followed by 6 to 8 hours of darkness (Dahl, 2001). To observe a production response in lactating cows, an intensity of 15 foot-candles at 3 feet from the floor of the stall is recommended (Dahl, 2001). However, dry cows exposed to 8 hours of light and 16 hours of dark produced 7 lb/day more milk in the next lactation (Miller et al., 2000). It is necessary for the walls and ceiling to be well insulated to minimize the problems with condensation in the winter and heat transmission by radiation in the summer. Insulation materials such as polyurethane spray, flexible fiberglass sheets, rigid panels, etc. are commonly used. To avoid moisture accumulation between the insulation and the roof, it is very important to seal the junctions. An additional consideration is that these insulation materials are highly combustible.

Lobeck et al. (2012) measured aerial ammonia and hydrogen sulfide concentrations in LPCV barns, naturally ventilated (NV) barns, and compost-bedded pack barns (CB). Ammonia concentrations (ppm, LS Mean ± SE) were 3.9 ± 0.35 for CB, 5.2 ± 0.35 for CV, and 3.3 ± 0.35 for NV barns. The CV barns had greater concentrations than CB and NV barns (P = 0.049 and P = 0.005, respectively), whereas CB and NV barns were similar. Summer had the highest concentration of ammonia in all three housing systems (P < 0.001). A separate analysis was performed to determine if there were differences in ammonia concentrations from the inlet to the exhaust side in LPCV barns. Ammonia concentrations were lower in the inlet side than the exhaust side of the barn (4.0 ± 0.27 vs. 6.2 ± 0.27, respectively; P < 0.001). Even though an increase in ammonia concentration was observed, this should be of no biological consequence as, according to the National Institute for Occupation Safety and Health (NIOSH), ammonia exposure should not exceed 25 ppm. Hydrogen sulfide concentrations (ppb, LS Mean, 95% CI) were 13, 9-19 for CB; 32, 22-45 for CV; and 17, 12-24 for NV barns. LPCV barns had higher concentrations than CB and NV barns (P < 0.006 and P = 0.044, respectively), whereas CB and NV barns were similar. Hydrogen sulfide concentrations (ppb, LS Mean, 95% CI) on the inlet side within LPCV barns were lower than the exhaust side of the barn (19, 11-34 vs. 41, 24-71; P < 0.001). As the air moved through the barn, it was picking up the hydrogen sulfide that was being released from the degradation of the manure. The recommended exposure limit for hydrogen sulfide by the NIOSH is 10 ppm.

In addition, there might be considerations about animal well-being that favor LPCV barns. Different housing types were evaluated (six LPCV barns, six compost-bedded pack barns, and six conventional naturally ventilated freestalls) in a study conducted on 18 commercial dairy farms in Minnesota and eastern South Dakota (Lobeck et al., 2011). There was a tendency for greater cow comfort (comfort index = cows lying down in a stall divided by all animals touching a stall; 85.9% vs. 81.4%) and stall usage (stall usage index = cows lying down divided by all animals in the pen not eating; 76.8% vs. 71.5%) in LPCV barns compared to conventional barns, respectively. Dairy cattle housed in compost-bedded pack barns had reduced lameness and hock lesions compared with those housed in freestalls. However, there were no differences in body condition, respiration rates, mastitis prevalence, culling, or mortality between housing types.

Main Advantages and Disadvantages of LPCV Systems

Advantages:

- maintain a controlled environment year round;

- produce a constant air velocity and air flow between cows that are lying down in the freestalls;

- reduce the distance between pens and the milking parlor, enabling cows to spend more time eating and resting plus reduced hoof wear;

- allow for greater control of flies and birds;

- might improve animal welfare

Disadvantages:

- greater energy use and fan maintenance costs due to forced ventilation year round;

- only useful for large facilities; minimum suggested is 400 cows;

- it can cause ventilation problems in the winter with temperatures below freezing because it needs a minimum number of fans working, and these reduce the temperature causing manure to freeze;

- In climates with high relative humidity, the cooling system by evaporation is less efficient to prevent heat stress than in dry climates.

Author Information

Fernando Díaz-Royón1, Marcia I. Endres2, and Álvaro D. García1

1Dairy Science Department, South Dakota State University

2 Department of Animal Science, University of Minnesota

Cited Literature

Brouk, M.J., J.F. Smith and J.P. Harner. 2001. Heat stress abatement in four-row freestall barns. In: Proc. of the Western Dairy Management Conference. Pp. 161-166.

Chastain, J.P. 2000. Designing and managing natural ventilation systems. In: Proc. of the 2000 Dairy Housing and Equipment Systems: Managing and planning for profitability. NRAES publication 129. Pp. 147-163.

Dahl, G.E. 2001. Photoperiod control improves production and profit of dairy cows. In: Proc. of the Western Dairy Management Conference. Pp. 27-30.

Harner, J.P. and J.F. Smith. 2008. Low-profile cross-ventilated freestall facilities – A 2-year summary. In: Proceedings of the High Plains Dairy Conference. Pp. 65-77.

Lobeck, K.M., M.I. Endres, K.A. Janni, S.M. Godden, and J. Fetrow. 2012. Environmental characteristics and bacterial counts in bedding and milk bulk tank of low-profile cross-ventilated, naturally ventilated, and compost-bedded pack dairy barns. Appl. Eng. Agric. 28(1):117‐128.

Lobeck, K.M., M. I. Endres, E.M. Shane, S. M. Godden, and J. Fetrow. 2011. Animal welfare in cross-ventilated, compost-bedded pack, and naturally ventilated dairy barns in the upper Midwest. J. Dairy Sci. 94:5469-5479.

Miller, A.R., R.A. Erdman, L.W. Douglass, and G.E. Dahl. 2000. Effects on photoperiodic manipulation during the dry period of dairy cows. J. Dairy Sci. 83:962-967.