Summary

Inadequate transition cow facilities can cause reduced dairy herd performance in the subsequent lactation. Facilities designed for transition and special-needs cows should facilitate the management plan and protocols developed by the dairy herd manager and team. As herds become larger and management demands for improved cow care increase, a variety of small “transition and special cow groups” emerge. This paper discusses the design process and design principles and defines the number and size of special cow groups based on field experience and observations of the authors as well as other literature. Properly designed facilities that consider cow comfort, worker safety, and the labor for managing and caring for these special cow groups will improve the dairy herd production as well as improve environmental protection.

Introduction

As dairy herds become larger and management demands for improved cow care increase, a variety of small “transition and special cow groups” emerge. Many producers and agricultural professionals are recognizing that managing these groups of animals more intensely can have a significant impact on total herd health and performance during the subsequent lactation. Properly designed facilities should consider cow comfort, worker safety, and the labor for managing and caring for these special cow groups as well as environmental protection. Recent research and field experience are also helpful in identifying the importance of considering the cow’s social behavior and comfort in the facility design to minimize the associated metabolic and production problems that occur with the known declining dry matter intake as the cow gets close to calving. A management plan and protocols for transition and special-needs cows, developed by the dairy herd management team, are the starting point for designing housing for special-needs cows. This should include a concise statement or bullet points stating the objectives for the care and handling of these special cows. Building designs that are sensitive to these varied needs and flexible enough to accommodate changing management requirements are the goal of the dairy facility designer. This paper discusses the design process and design principles and defines the number and size of special cow groups based on field experience and observations of the authors as well as other literature.

The Design Process

The design process is important in developing a functional and practical facility design. It allows for input from all the dairy design team members. The design process also makes it easy to investigate and consider alternatives and evaluate how different components interact to produce an overall system design. Design is an iterative process with continual evaluation of alternatives and how they affect the management plan. The design process includes several distinct steps:

- Assembling a dairy design team and gather necessary information.

- Developing a transition cow management plan.

- Investigating and developing alternative designs that will help implement the management plan.

- Evaluating design alternatives and options.

- Choosing the “best” system design.

- Implementing and troubleshooting the design.

Transition and Special-Needs Cow Management Plan

The special-needs and transition cow management plan addresses the first step in the design process. The management plan describes:

- Number of defined management groups.

- Number of cows in a management group.

- Nutritional needs of the group.

- Health needs of the group.

- Working protocols of the group.

- Pen design for the group.

- Housing system and environment for the group.

- Handling and restraint needs of the group.

- Cattle movement between groups.

The management plan helps to identify the design specifications for the building, penning, and environment of the facility. A well-designed facility will include the desired elements to develop a functional and labor-efficient facility. The frequency of observation and intensity of management will also impact the building design.

The building design and management for a large herd can usually assume that there is frequent monitoring (every hour) of the maternity area. This allows the cow to be moved immediately into a calving pen from a close-up cow pen when the calf’s feet are showing. This might lend itself to a building design with a close-up cow freestall pen and a separate well-bedded maternity pen that the cow is moved into during calving.

A different building design is required when there is infrequent monitoring (every 6 hours or more) of the maternity pen with long periods of time when cows may be alone to calve on their own. This might lend itself to a building design with a well-bedded group pen system for the cows due to calve in the next 7 days where the cow could calve in the unmonitored 6 to 8 hour period. This also requires that pens be maintained and cleaned properly during the time available to the farm labor.

Dairy Design Team

Formation of a dairy design team is important for developing the management plan and ultimately the facility design. The makeup of this team may change as the process progresses. A dairy team might include:

- Owner

- Herd manager

- Farm managers

- Farm labor

- Agricultural professionals such as:

- Nutritionist

- Veterinarian

- Agricultural engineer

- Builder

- Equipment supplier

Identifying Design Features to Implement the Management Plan

The design team requires that information be collected and analyzed to determine which problems or issues need to be addressed in the management plan and implemented in the design. Herd health records such as calving difficulty, displaced abomasum, ketosis, milk fever, mastitis at freshening, or cows off feed can be used to identify design features and management protocols that can be implemented to reduce these occurrences. These occurrences may be attributed to either a limitation in the facility design, not providing design features that allow the desired management protocols, or not implementing the protocol defined in the management plan.

It is important to get the design team’s input on which features are required and which are optional. The design specifications should be documented and referenced frequently during the planning and design process. Identify and prioritize the required and optional features to help the team make decisions during the design process. When decisions need to be made with a limited budget, the prioritized list will help determine those features that are necessary to the management plan as compared to those that “would be nice” if the money is available.

Transition and Special-Needs Cow Management Groups

The transition and special-needs cow groups to be managed and the number of cows in each group must be defined for a specific farm’s management plan. Transition cows are from 1 to 3 weeks pre-calving until 1 to 3 weeks post-calving. Stone (2000) defined the special-needs cows as those needing individual attention.

Typical transition and special-needs cow groups are:

- Transition Cow Groups

- Far-off dry cows (20 to 40 days after drying off)

- Close-up (prefresh) dry cows (3 to 4 weeks before calving)

- Close-up (prefresh) heifers (3 to 4 weeks before calving)

- Maternity (calving) cows (<1 day)

- Maternity (calving) heifers (<1 day)

- Fresh cows (2 to 4 weeks after calving)

- Fresh heifers (2 to 4 weeks after calving)

- Special-Needs Cow Groups

- Working group (1 day)

- Fresh cows—milk held (2 to 4 days)

- Lame and injured cows (1 to 21 days)

- Treated cows—milk held (1 to 10 days)

- Mastitis cows (1 to 7 days)

- Sick cows (1 to 7 days)

- Quarantined cows (1 to 7 days)

- Cull cows (1 to 7 days)

The time frame guidelines identified for a group are based on recommended practices and experience and should be defined in the management plan. When possible, heifers and cows may also be grouped separately as herd size increases.

When possible, use herd records to plan for pen capacity for transition cows. Special-needs cow pen capacity will be harder to plan for since it is dependent on the incidence of the disease and the time period the cow group will be housed. Depending on the herd size, some of these cow and heifer groups can be consolidated to create group size or pen size that is practical.

Transition Cow Groups

The close-up cows and heifers are moved to a group or pen from 1 to 3 weeks before the expected calving date. This is typically decided by the herd manager according to his or her own experience and facility capacity.

Optimum cow comfort and special attention to monitoring dry matter intake is important to minimize metabolic disorders associated with the imminent calving. As the cow gets close to calving, she can be moved to an individual pen to minimize stress. Fresh cows are observed for 1 to 3 weeks after a calving. Dry matter intake and the temperature of the cows are monitored daily to identify cows that are not eating or will require additional care. Providing a separate fresh cow group and extra attention typically results in improved performance throughout the subsequent lactation.

Special-Needs Cow Groups

Many times it will enhance the performance of the dairy if there are groups of cows that are kept separate from the main stream cows because of some other special needs. This would include lame, injured, and slow- or hard-milking cows. Lactating cows that have been treated are kept in a separate group to lower the risk of contaminating the bulk tank with a drug residue. The time period a cow spends in the special-needs cow group is typically 1 to 10 days depending on treatment time and withholding time for the drug used. Cull or market cows, for example, may be accumulated over a week’s time and scheduled to be removed from the farm on a regular basis. Treated cows may be housed for 10 days depending on the type of treatment and the withholding time of the treatment drug. Many large dairies also have an area used for holding market or cull cows. This area may also be used to hold dry-off cows for a day or two while they get a reduced ration to help lower milk production before milking is stopped. These pens need to hold about 0.5 to 0.7% of the herd and should provide for water, convenient feeding, resting, and access to a loading chute.

Isolation Group

Every dairy should have a plan for handling cows suspected of having an extremely contagious disease or animals entering the herd from another farm. This should be completely separate from the rest of the cows to minimize the likelihood of spread of the disease. In many cases, the best way to handle this may be to truck the cow to an unused barn away from the milking animals until the diagnosis is confirmed. A veterinarian familiar with the regulations and practices required to handle cows with infectious diseases should be consulted concerning the best practices for these cows. In most states, the state veterinarian or similar office has authority over the ultimate handling of cows with reportable contagious diseases.

Determining the Management Group Size

Dairy producers and agricultural professionals have identified that variation in transition cow management group numbers and the subsequent overcrowding of pens during the transition period is the biggest challenge in facility design. The inability for management to implement the desired management plan due to inadequate pen capacity creates many of the metabolic and health-related problems that could be minimized with an adequate facility design. Overcrowding is of most concern for the submissive cows in a large group that may not be able to compete for feed at the bunk or be able to lie down because the resting space is full. This decision must be balanced with the additional cost to build for meeting a condition that occurs only for 1 to 2 months of the year.

The number of cows in a transition cow and special-needs group is dependent on herd size, calving interval, reproductive efficiency, culling rate, and the time period the groups are housed. Some management groups may be consolidated depending on herd size, time frame in the group, and intensity of observation and management. The compromise of managing groups rather than individual animals is determined by the management plan. For a large herd, the number of animals for a specific cow group may be large enough to justify a separate pen for the group. As herd size decreases, the appropriate cow groups may be consolidated to create a larger number of cows for the pen.

Figure 1 shows the typical management groups and the possible consolidating of appropriate cow groups as herd size decreases. As the herd size decreases, the number of cows in a specific management group may become so small as to not be a practical pen size. It may be necessary to consolidate some groups. As herd size increases, the number of cows in a management group becomes a practical pen size. For example, for a large herd, it may be desirable to have separate close-up heifer and close-up cow groups since the number of cows or heifers in each group may be a reasonable pen size. For a smaller herd, the close-up cows and heifers may be consolidated into a single pen to create a reasonable pen size.

Using Farm Records to Determine Management Groups

The best design information on management group sizes for a specific farm comes from the farm’s own calving and health records. A weekly or monthly report of cows, heifers, and total calvings from a herd management software package over a 12- to 24-month period helps in developing realistic numbers for each management group’s time frame.

Designing the group (pen) capacity based on the average weekly or monthly number of calvings creates a situation where the pen is overstocked for half the year. The variation of calvings for the herd over time should also be accounted for in the pen design capacity. One approach suggested here is to determine the group (pen) design capacity to accommodate the variation of calvings for a specified percentage of time. For example, using herd data of weekly calvings, the 90th percentile of calvings could be used as the pen or group design capacity. This pen capacity meets the herd needs 90% of the time, or 47 out of 52 weeks. That also means 10% of the time, or 5 weeks out of the year, the pen is over capacity. Compensation for too many animals is done by overpopulating, finding other space, shortening the occupancy time, or changing management protocols.

Figure 2 shows the total weekly calvings over approximately a 2-year time frame for a 1,600 cow herd. Note the variation of calvings over time. There were approximately 45 out of 100 weeks that the number of calvings was higher than the average of 31 calvings per week. The 90th percentile of 43 calvings per week is also shown. This is equivalent to 139% of the average weekly calvings. If the pen were designed to hold this capacity per week, there would have been only 8 out of 100 weeks that the number of calvings would have been higher than the pen capacity. For the other 10% of the time, the pen could be managed by adjusting the time period the cows are in the pen. The manager could remove cows doing well in preference for the cows coming into the pen that need space and not overcrowd the pen. This maintains the priority of having an adequate environment including feed space and resting space for all the cows rather than overstocking the pen and affecting the entire group. A 1- to 3-day adjustment in the time a specific cow is in the pen may have less effect on that cow as compared to overstocking the pen and having inadequate resting or feed space for the entire pen for 1 to 3 days.

Using Summary Herd Data to Determine Management Groups

When individual farm calving records are not available, the design assumption needs to be based on other available data. In this case, the design assumption is less accurate in predicting variation within a specific herd. However, field experience and summary herd data do indicate a similar design principle. Stone (2000) noted many times the transition cow pens are overstocked over the course of a year. Only 10% of the herds were not overcrowded at some time during the year. Based on this analysis, Stone recommended that the pens be designed for between 25 to 35% more than the uniform calving numbers.

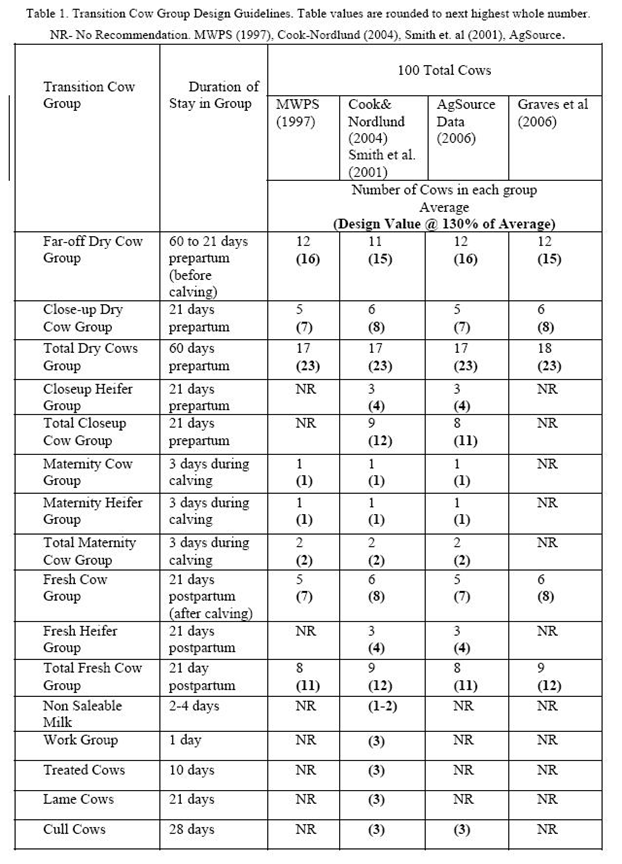

Table 1 shows suggested design guidelines on an average herd makeup from several references. MWPS (1997) uses basic assumptions to calculate the average group size. Nordlund and Cook (2004) as well as Smith et al. (2001) suggest another set of guidelines based on calculations and field observations. The AgSource column uses the aggregated monthly calving data from 4,500 Wisconsin dairy herds to determine group sizes for the specified time period. Graves et al. (2006) suggested a simple spreadsheet calculation used to determine group sizes. All table values were rounded up to the nearest whole number. The table values include the average value and a suggested design value based on 30% more than the average value.

Pen and Facility Design Principles

There are several design principles to consider in the pen and facility design process. The pen design philosophy for transition and special-needs cows is different from the typical lactating cow pen design. The tendency in designing pens for lactating cows is to maximize space utilization. However, research and field experience suggests that when designing for transition and special-needs cows, an important design principle is providing “extra space.” Many dairy managers and professionals seem to agree that extra feed and resting space and wider travel lanes all help provide optimum cow comfort. While difficult to quantify, benefits from extra space also include increased cleanliness, health, and productivity. Inadequate feed and resting space can result in metabolic problems and injuries that keep cows from entering the milking herd at the appropriate time and in the best condition possible.

Cow Comfort

Comfort for transition cow groups is recognized by many dairy professionals as a high priority in facility design. Cows that are under stress due to calving, illness, or injury can benefit from having a low-stress living area. Design features that can reduce living stress include:

- Small number of cows in a group.

- Free movement without being jostled and shoved by other cows.

- Minimizing regrouping and moves between groups.

- Easy, continuous access to fresh feed and water.

- Clean, dry, well-bedded resting area.

- Plenty of space in freestalls or on a bedded pack to recline and rise.

- Enough freestalls or bedded pack space to always have a place to lie down.

- Confident, slip-free walking conditions.

- Plenty of fresh, dry air.

- Dry, draft-free conditions in the winter.

- A shady, breezy location during hot weather.

Provide the best environment possible with space, water, ventilation, and floor surface for these cows to relieve the stress of the calving process. Properly sized freestalls or adequate resting area space and plenty of alley space provides for excellent cow comfort with reasonable labor and bedding demands. Size the pen to assure that all cows have a stall or adequate resting space during maximum use periods. Provide excellent lighting (25 to 35 foot candles) for good observation of animals and even higher light levels (50 foot candles) in animal treatment and work areas.

Feed Space

Recommendations from Cook and Nordlund (2004) suggest transition cows should have access to 0.75 m (30 inches) of bunk space with head locks spaced at 0.750 m (30 inches) or with 0.60 m (24 inches) headlocks stocked to only 80 to 85% of the feeding space capacity independent of the number of stalls in the pen. Use headlocks designed to facilitate easier extraction of a downed animal and to minimize the risk of choking when a cow is down. Post-and-rail feeding fences can artificially reduce the accessible feed bunk for submissive cows when a dominant cow commands more of the usable bunk space than she needs.

Resting Space

To provide optimum cow comfort and cleanliness for the transition cow, additional space should be the guiding design principle. Recommended freestall dimensions are dependent on the size and breed of the cow. In general, freestall sizes are larger than the average of the herd size since cows in this stage of calving are larger and more awkward. This is a result of increases in cow size and the physical needs for cows to recline and rise in a natural, stress-free manner. An individual bedded pen is sized to be 3.7 m x 3.7 m (12’ x 12’) pen or 13.7 m2 (144 ft2) which is the minimum size recommended for a calving cow.

Extra space in a bedded pen and plenty of bedding can increase the comfort and cleanliness without the necessity of intensive and frequent grooming and cleaning. More densely populated packs and smaller pens require more frequent grooming, bedding addition, and cleanout to keep cows clean and comfortable. A resting area of 9.5 to 19 m2 (100 to 200 ft2) per Holstein cow is recommended in a group bedded pen. The space needed per cow is largely dependent on bedding frequency and ability to keep the animals clean. Fresh cows’ udders are very susceptible to dirty resting conditions, so larger pack areas and meticulous bedding maintenance are recommended. This resting space does not include the feed alley used for accessing feed and water. Natural Resource Agriculture, Engineering Service (NRAES), Midwest Plan Service (MWPS), and other design information can be consulted to obtain the current recommendations for space and freestall dimensions.

Relationship between Feeding and Resting Space

Dairy nutritionists and other professionals recognize that dry matter intake diminishes as calving becomes imminent. Pen design should not create any additional limitations on feed intake. Providing adequate feed space and minimizing competition at the feed bunk is an important design principle in transition cow pen design. Resting space is determined after determining the required feed space and assuring there is more than enough resting space for all cows at all times.

Animal Behavior

Cook and Nordlund (2004) suggest that minimizing the number of pen moves can reduce competition and social stress that occurs during the time period after the move. It can take between 3 to 7 days for a cow to adjust her social status after a pen move. During this social adjustment period, she is under additional stress. Field recommendations suggest cows be moved to a maternity pen as close to calving as possible, and moved out of the pen soon after calving to minimize social stress.

Labor Savings in Cow Management

Prompt and proper care during this critical period in a cow’s annual life cycle can be considered the foundation on which a cow builds a profitable lactation and provides a healthy replacement animal. Facility design needs to take into account labor requirements for performing the cow care tasks required. This is where the herd manager and veterinarian spend most of their time. It is extremely important that arrangements are convenient for them to make the most efficient use of their time. A list of the working protocols and a description of the facility features allowing the protocols to be implemented should be developed for each transition and special-needs cow group.

Worker Safety

Worker safety considerations should be part of the management and facility plan. Items to consider include animal control measures, methods for workers to escape from aggressive animals, elimination of pinch point or entrapment hazards between the worker and the animals, good footing for both workers and animals, and adequate lighting.

Biosecurity

Biosecurity measures to provide protection from diseases both on and off the farm are also a fundamental design principle. There are two general categories of biosecurity: 1) keeping diseases from entering the farm through animals from off the farm, herd health providers, delivery vehicles, equipment, wild animal vectors, and visitors; and 2) preventing on-farm spread of disease among different groups of animals. Designers must consider both aspects of biosecurity when designing and locating transition special-needs cow facilities. Special-needs animals can be both the source of disease or may be some of the most susceptible animals to diseases.

Close-up Pen

The close-up pen should be under constant observation so the cow can be moved to a well-bedded calving pen at the time of calving. Selection of resting space for the close-up pen is based on personal preference and the dairy management plan. The cow will remain in the calving pen until completion of calving and moved out of the pen to the fresh cow pen environment.

Freestall Pen Design

Freestall pens for close-up and fresh cows are an appropriate environment up to the point of calving. A freestall should provide a clean and dry place for the cow to lie down and be sized to prevent unnecessary forces on the cow or injury as a cow rises and reclines. The freestall resting surface should also be easily accessible from walk alleys. The freestall dimensions should be sized according to the largest cows expected in the transition cow group. (Cook & Nordlund, 2004)

A 2-row freestall pen design is an efficient pen layout providing the recommended feed space of 0.75 m (30 inches) per cow and having the correct number of freestalls for resting space without wasting space. Additional crossovers between rows of stalls not only allow easy access to the bunk but also increase the feed space per cow. There should be a freestall available for every cow in the pen. A head-to-tail freestall row arrangement allows easy observation by the manager of the rear of the animals as the manager walks up the feed lane.

Freestall pen designs with 3 rows have limited feed space on a per cow basis, which does not efficiently use the resting space of the pen. The 3-row pen design should be stocked according to recommended feed space per cow and will typically have fewer cows in the pen than the number of freestalls in the pen.

Group Bedded Pen Design

Bedded pens in a barn design for a small herd may be a better design option. This option is best used when management cannot monitor cows round the clock or the calving date is uncertain. When constant monitoring is not possible, the risk of not getting the cow out of a freestall pen and into the calving pen at the appropriate time increases. If the calving date is missed by a few days, the cow can calve in a clean, bedded pen environment as compared to calving in a freestall pen. Bedding should be added regularly to provide a clean and dry place for cows to lie and potentially calve on. The pen arrangement should allow easy bedding addition and manure pack removal with a front-end loader.

Maternity (Calving) Pen Design

Individual maternity (calving) pens should be approximately 3.7 m x 3.7 m (12’ x 12’) or 3 m x 4.3 m (10’ x 14’) or approximately 13.7 m2 (~144 ft2). The base of the pen can be concrete, clay, or sand. At least 0.15 m (6 inches) of organic bedding should be placed on top of the base. Although concrete floors are more easily cleaned, they may not provide the best footing. Clay, dirt, or sand bases allow better footing for the cow and allow relatively easy cleaning of the pen when accessed by a skid steer. Rubber mats may also be used.

Sanitation is an important design consideration in individual pens used for maternity pens and treatment areas. Bedding should be removed and replaced with fresh, dry bedding after every calving. Frequent manure removal is necessary to prevent the transmission of diseases such as Johnes by contact of the newborn calf with the cow’s manure. The maternity pen design should include a water space and a headlock with gates positioned to allow funneling the cow into the headlock for treatment and milking after calving. A vacuum line can be placed above the pen to allow milking out colostrum in the pen before moving the cow. Cows may need less than 1 day of housing in a maternity pen, but some flexibility for this group is warranted due to calving difficulty and/or the uncertainty of due date.

Treatment of Convalescent Pen Design

An individual pen to treat and handle downer cows and other serious health problems is also needed. A pen for one cow should be at least 3.7 m x 3.7 m (12’ x 12’) or 13.7 m2 (144 ft2) with gate partitions, water supply, and a feed trough. The pen should include a lockup and gate arrangement allowing one worker to easily catch a cow for close examination. Use long gates instead of fixed pen sides whenever possible to provide better access while working on cows. There should be special equipment for supporting and manipulating sick or downer cows such as an overhead lift system or other cow support aid. Include easy access to these from outside the building for delivery or removal of immobile cows.

Cow Sorting and Group Handling

Cows needing attention are often diverted from the return lane after milking. Following are common reasons for sorting cows:

- Bad milk

- Injury

- Regrouping

- Breeding

- Hoof trimming

- Dry off

- Culling

- Vaccination

- Pregnancy check

- Sick

- Computer-identified variance

Use either manually operated gates or computer-controlled selection gates to sort cows as they leave the milking parlor. However, the sorting activity or location should be far enough away from the parlor exit so that the milking routine is not disrupted. Cows may be diverted into a stacking lane running parallel to the return lane or to a holding or sorting pen. The pen should be sized to hold all sorted cows while they are awaiting further handling or treatment. At a minimum, a short-term sorting facility should be sized to hold one side of the milking parlor. There are a variety of destinations for cows after separation from the return lane. The first stop may be a short-term holding pen where animals are held for a quick examination and treatment before returning to their housing group or directed to another area with facilities for longer-term holding or treatment. Cows requiring only quick attention can be cared for and immediately returned to their milking group.

A short-term holding pen should be sized to have at least 2 m2 (20 ft2) of area per cow. This does not provide adequate room for cows to lie down, so occupancy should be kept to less than 1 hour. Cows should not be kept standing and away from water any longer than the normal milking period. These pens need to have gates hinged in such a way that the cows can be corralled into a single alley leading to the equipment being used. Using the radius of the gate with beveled corners and lanes help to accomplish this. There should be easy access for people to get in and out of the pens and the ability to handle cows without getting trapped or reaching through fences. Provide ways to keep the short-term holding pen clean with a minimum amount of handwork. Flushing or a large volume wash-down hose can be the most convenient way to clean this area. Often a combination of hand scraping and hosing provides a labor-efficient method and reduces water use and wastewater disposal. Slopes and elevations along with manure collection points are critical to get the job done effectively.

Some animals may be moved to an intermediate holding area while awaiting a visit by a veterinarian, hoof trimmer or breeder before being returned to their housing group. Cows held in holding pens longer than 1 hour should have access to water. Cows held longer than 2 hours should have access to water, feed, and a comfortable resting area. The importance of access to water, feed, and resting increases with the length of time a cow is held in a pen. Headlocks are important if the pen is used for initial examination and simple treatment.

Animal Handling or Drover Lane

Animal handling or drover lanes or alleys are another addition that can ease the labor and management of the cow groups needing attention in the transition cow barn. With a well-laid-out pen system and a drover lane, one person can move and manage cows. The drover lane is placed adjacent to a series of group pens along the length of the building so that any pen can be accessed. This is an especially important design feature for large herd barn designs with multiple pens. The drover lane allows cows to be moved from one pen to another without disrupting the routine of other pens or having to move cows through other pens. Gating and penning should be designed to allow one person to move an individual cow from one pen to another easily.

Support Facilities

Several support facilities can be used by the herd manager, veterinarian, and workers to implement the management plan for transition and special-needs cows. A short description of some of these areas is discussed below.

Office(s), Work Space and Storage Building

Any special-needs area should have a secure space for record keeping and storage of medicines and equipment and hot and cold running water.

Veterinary Office and Storage Area

An office and storage area for veterinary activities, equipment and supplies should be located in close proximity to where the most work will be done. There should be provisions for the following items.

- Excellent lighting

- Convenience outlets

- Telephone

- Heating and air conditioning

- Computer

- Refrigerator

- Hot and cold running water

- Wash sink and wastewater disposal

- Drug storage

- Semen tanks

- Desk and filing cabinet

- Supplies

- Parking for veterinary vehicle

- Waste disposal for veterinary/medical waste

This area should be near special treatment and restraint areas where extensive health-care procedures such as surgeries are likely to take place. In cold climates, it is advisable to have part of the treatment area heated. Areas where intensive and perhaps distressing treatments are performed should be located away from the holding area and cows traveling to and from milking so cows are not distracted.

Herdsperson Office

Many dairy farm owners and managers are recognizing that the herdsperson’s office should be near the transition cow management groups since this is where a lot of their time is spent with cows calving and monitoring health of fresh cows. This office space can be located adjacent to the transition cow pen or barn space to allow easy access to the cows.

Treatment and Handling Facilities

It is beyond the scope of this paper to provide detailed design and construction information for treatment and handling facilities. Some of the equipment that may be used and the space requirements follow:

- Palpation or management rail for pregnancy checking and giving injections.

- Single lane chutes with raised personal walkways beside for giving injections.

- Wide alleys or rectangular catch pens with headlocks along one side to temporarily lock up several cows for neck and head access. Enticing cows into these headlocks may be a problem.

- Squeeze chutes with head gates are often used for more extensive work.

- Hoof trimming table or chute. If a portable unit is used, there should be easy access for getting it in and out of the barn.

- Holding areas for animals awaiting trimming and leaving the trimming unit.

Milking Area for Treated Cows

Consider how cows in this area will be milked. There should be provisions for milking a cow that cannot walk to a milking parlor. If the farm’s milking parlor is to be used, be sure the location and access is convenient for cows to walk to the milking parlor. For large herds, it may be desirable to develop a milking area or parlor for milking treated cows so unsalable milk does enter the main parlor milk storage. The risk of treated milk contaminating a salable storage tank of milk can be minimized by separating the milking of these cows from the normal parlor milking setup. The small transition and treated milking groups can also interrupt and delay the normal procedures of the main parlor. A single-sided parlor, flat barn parlor, or simply some single milking units for sick or mobility-challenged cows can be used.

Newborn Calf Care Facilities

An area to process newborn calves may include facilities for storage, preparation, and handling of frozen colostrum and a heating pad or box for newborn calves.

Flexible Facility Design and Layout

The most important consideration in designing for transition and special-needs cows is flexibility and multi-use. The needs of herds vary from herd to herd, throughout any given year for a herd, and throughout the life of a dairy (new herd, expanding herd, young herd, older herd). The transition and special-needs barn should be designed with similar criteria for ventilation, resting areas, and floor surfaces as other freestall and loose housing barns. Drive-along feeding and straight-line manure scraping or flushing consistent with the other barns on the farm are best.

Location of Transition and Special Needs Cow Barn

The location of the transition and special-needs facility in relation to the rest of the dairy facilities is a very important consideration. It is usually best to locate this facility close to the milking center so the fresh cows have a short distance to travel to the parlor and back. The barn should be easily accessible for employees, veterinarians, service vehicles, and trucks for loading and unloading cows.

Expansion Planning

Herds that are or will undergo expansion place different requirements on the transition and special-needs barn design. The number and distribution of animals in the transition and special-needs groups will change from the current situation as the herd grows. The design for transition and special-needs facilities should either leave space for future expansion or provide for the ultimate requirements in advance.

Flexible Use Pen Design

Additional crossovers in a freestall pen allow the pen to be subdivided into pen areas. Movable gates in the pen allow the separate groups within the pen to be resized depending on the cow flow into the pen and the desire of the manager. This minimizes the social stress of separating pen mates since the cows may be in the same pen and separated only by a gate. The additional crossovers also help to increase the bunk length for the pen space, lessening competition at the bunk, and provide additional options for water locations.

Develop Alternative Designs

Based on the management plan and the design principles and considerations discussed above, several alternative facility designs can be developed. The design specification lists and other information can be used to develop creative ideas and options. Farm visits, popular press articles, and visits with agricultural professionals can also fine-tune design decisions. Find those designs and specifications that best fit into your management plan. Use Midwest Plan Service (MWPS) and Natural Resources, Agriculture, and Engineering Service (NRAES), and Extension publications for transition and special-needs pen and barn plans and specific design recommendations.

Choose the “Best” Facility Design

There is no single “best” design. Every design involves trade-offs. The planning and design process incorporates the design criteria desired into a functional, practical, and reasonable plan. Some design principles may have to be compromised slightly to be part of the overall design. If the design principles have been prioritized, the job of deciding which features to keep or eliminate for whatever reason can be made more easily because the decision process is already in place.

Assess the trade-offs of each facility design option. Try to determine which combination of design choices provides the most balanced design. The “best” solution should meet all of the required criteria set forth in the management plan and building specifications and most of the highest-ranked desired features. The final facility design should be somewhat “better” than the other alternatives.

Implement the Design

A transition cow facility should be designed and built to implement the chosen management plan and provide a clean, dry environment with plenty of fresh air and feed and water for the animals. A well-designed facility should also be labor efficient, economical, safe for both workers and cows, and environmentally friendly.

A scaled plan or sketch should be developed for discussion with the dairy design team and for bidding or building purposes. The plan helps define the space and communicates to the team and the builder the specifications of what is to be built. The scaled plan can be used to evaluate the overall design and its impact on all aspects of the management plan. The dairy design team can review and critique the design. The herd manager and other employees can consider how they will perform their assigned tasks. The scaled plan can be used to evaluate cow flow from pen to pen, feeding and manure handling equipment traffic, and work protocols and routines. The plan and list of specifications describes the facility in terms a builder or contractor can understand.

Conclusions

A good transition and special-needs cow housing design facilitates the objectives and requirements of the dairy cow management plan. Facility design is a fluid process involving give and take. It is easy to lose sight of the original intent along the way. Design the facility to implement the transition cow management plan. As decisions are made, they should be tested against the requirements and objective of the management plan. The ultimate decision should be based on the answer to the question “Will this design, change or device help the farm managers, workers, and cows to reach the goals and objectives of the management plan?” Consider each of the design features to develop a comprehensive facility design. Designs that are sensitive to a variety of herd and management needs and flexible enough to accommodate changing management requirements should be the goal of the dairy facility designer. The design must also consider the health and safety of those working with and around animals and biosecurity measures to minimize the spread of disease among animals on the dairy or moving onto and off the dairy.

Resources

AgSource Cooperative Services. 2006. P.O. Box 930230. Verona, WI 53593. Phone: 608-845-1900, fax: 608-845-1999. www.agsource.crinet.com/.

Cook, N., K. Nordlund. 2004. Behavioral Needs of the Transition Cows and Considerations for Special Needs Facility Design. Veterinary Clinics of North America: Managing the Transition Cow to Optimize Health and Productivity. Edited by Cook, N.B., Nordlund, K.V. www.vetmed.wisc.edu/dms/fapm/publicats/chapters/behavioral_needs.pdf.

Engle, R., and R. E. Graves. 2006. Guidelines for Special Needs Barns. Dairy Practices Council Guideline. DPC 88 Yellow Copy 13 pages. Available at: www.dairypc.org.

Graves, R. E., R. Engle, J. T. Tyson. 2006. Design Information for Housing Special Cows. ASABE Meeting Paper No 064034. July 9-12, 2006. 11 pp. www.asabe.org.

Graves, R. E., D. F. McFarland, J. T. Tyson, and T. H. Wilson. 2006. Penn State Housing Plans for Milking and Special-Needs Cows. Natural Resources Agriculture and Engineering Service. NRAES–200. Available at: www.nraes.org.

Kammel, D.W. 2006. Internal Communication. 460 Henry Mall. Madison, WI 53706. dwkammel@wisc.edu

.

Kammel, D.W., K. Janni. 2000. Facility Design for the Transition Cow. Proceedings from the Conference Dairy Housing and Equipment Systems. February 1-3, 2000. Camp Hill, PA. Natural Resource Agriculture and Engineering Service, Cooperative Extension, 152 Riley Robb Hall, Ithica, NY 14853- 5701. www.nraes.org.

Kammel, D.W., T. Rehbein, S. Gunderson, R. Thompson. 2000. Transition Cow Case Studies. Proceedings from the Conference Dairy Housing and Equipment Systems. February 1-3, 2000. Camp Hill, PA.

Natural Resources Agriculture and Engineering Service, Cooperative Extension, 152 Riley Robb Hall,Ithica, NY 14853-5701. www.nraes.org.

MWPS. 2000. Janni, K., D.W Kammel. Special Cows/Special Care: Case Studies. Four State Dairy Management Seminar. Cows in Transition. Agricultural and Biosystems Engineering Department, 122 Davidson Hall, Iowa State University, Ames, IA 50011-3080. www.mwps.org.

MWPS. 1997. Dairy Freestall Housing and Equipment. MWPS-7. Agricultural and Biosystems Engineering Department, 122 Davidson Hall, Iowa State University, Ames, IA 50011-3080. www.mwps.org.

NRAES. 1997. Penn State Dairy Housing Plans. NRAES-85. Natural Resources Agriculture and Engineering Service, Cooperative Extension, 152 Riley Robb Hall, Ithica, NY 14853-5701. www.nraes.org.

Smith, J.F., J.P. Harner III, M.J. Brouk. 2001. Special Needs Facilities. Kansas State University Agricultural Experiment Station and Cooperative Extension Service. EP 100. http:/www.oznet.ksu.edu.

Stone, B. 2000. Defining and Managing Special Cows. Proceedings from the Conference Dairy Housing and Equipment Systems. February 1-3, 2000. Camp Hill, PA. Natural Resources Agriculture and Engineering Service, Cooperative Extension, 152 Riley Robb Hall, Ithaca, NY 14853-5701. www.nraes.org.

Source: 2007 International Dairy Housing Conference, Minneapolis, MN. ASABE Publication No. 701P0507e. Copyrighted by the American Society of Agricultural Engineers (ASABE). Used with permission of ASABE, the publisher.

Author Information

David W. Kammel1 and Robert E. Graves2

1 Biological Systems and Engineering, University of Wisconsin-Madison

2 Department of Agricultural and Biological Engineering, The Pennsylvania State University