Abstract

The Penn State TMR and Forage Particle Separator (PSPS) has become a routine technique used in forage and TMR particle size evaluation. The objective of this paper is to outline the procedure to estimate particle size using the PSPS and to briefly describe how it may be used to further understand rumen fermentation and feeding behavior. Although proven useful, a large proportion of smaller TMR particles may pass through both sieves of the original device. Recently, a smaller sieve measuring 1.18 mm has been added to improve accuracy of estimating the smaller particle fraction. The PSPS is also a useful tool to monitor sorting behavior of dairy cattle and can be used to troubleshoot a variety of feeding, digestion, metabolic, and production-related problems. Plotting the particle size distribution of both TMR and refusals using a newly developed spreadsheet can also be useful in evaluating the degree of sorting behavior exhibited by dairy cows.

Introduction

Since its introduction in 1996, the PSPS has become a routine technique used in forage and TMR particle size evaluation. The rapid acceptance of this method is due to the simplicity of the procedure, low cost of analysis, and rapid determination of results. The PSPS was originally constructed out of two sieves and a bottom pan. Apertures of the two sieves measured 19.0 and 8.0 mm and had thickness of 12.2 and 6.4 mm. With its simple construction and size, the PSPS sieving method can be frequently implemented on the farm and used at the time of harvest or feeding to determine particle size of forages or TMR (Lammers et al., 1996). Even though the apparatus has been widely accepted and particle size measurements using the PSPS are now commonly reported in the scientific literature, the TMR typically contains 40 to 60% concentrate, most of which passes through the smallest sieve measuring 8.0 mm. Recently, a smaller sieve measuring 1.18 mm has been added to improve accuracy of estimating the smaller particle fraction. The purpose of this paper is to outline some of the recent developments and understandings in the TMR particle size measurement as estimated by the PSPS.

Using the Penn State TMR and Forage Particle Separator

Sieving Frequency

The PSPS must be operated correctly in order to achieve accurate results. During our field experience, we have observed that the rate of shaking, or frequency of moving the device, sometimes differs between users. Because the frequency of shaking will influence particle movement over enclosed sieves and will ultimately affect particle size estimates, we have recently tested the effect of shaking frequency on TMR particle size measurement (Kononoff et al., 2003). The unit used to express frequency of movement is a Hertz (Hz), and one Hertz is equal to the number of full forward and backward movements within one second. For example, if the PSPS is shaken at a frequency so that a total of 66 full movements (forward and back) would occur within 60 seconds, the measured frequency would be 1.1 Hz. In the experiment, three frequencies, 0.9, 1.1, and 1.6 Hz (slow, medium, and fast) were used to determine the effect of sieving frequency on TMR particle size estimation.

Results of the experiment are listed in Table 1 and indicate that reducing sieving frequency below 1.1 to 0.9 Hz resulted in significantly more material being retained on the 19.0 mm sieve and less on the 8.0 and 1.18 mm sieves. Consequently, these results yield a mean particle length (MPL) that was significantly greater when estimated at 0.9 Hz compared to 1.1 Hz. In contrast, increasing sieving frequency from 1.1 to 1.6 Hz did not result in significant differences in particle size measurements. We recommend the PSPS to be shaken at 1.1 Hz (66 cycles/min) or greater. Practically, it is important to understand that one cannot shake the PSPS too fast; however, movements which are too slow may result is very different estimates of particle size. It is recommended that operators of the device calibrate the frequency of movement over a distance of 17 cm for a specified number of times. The number of full movements divided by time in seconds results in a frequency value that can be compared to this recommendation.

| Particle size (mm) | Frequency (Hz)2 | P – value | ||

|---|---|---|---|---|

| 0.9 | 1.1 | 1.6 | ||

| TMR1,3 | ||||

| >19.0 | 40.9a | 6.4b | 6.9b | 0.02 |

| 19.0 – 8.0 | 24.6b | 42.9a | 43.8a | 0.05 |

| 8.0 – 1.18 | 31.5 | 36.7 | 35.3 | 0.31 |

| <1.18 | 3.0b | 14.0a | 14.0a | 0.001 |

| MPL (mm)4 | 11.2a | 5.8b | 5.7b | 0.01 |

|

1TMR containing 50:50 forage-to-concentrate ratio and 9.5% grass hay, 25.3% corn silage, and 14.6% alfalfa haylage (% of DM). 2Means in the same row with different superscripts differ (P < 0.05). 346.0 + 1.6% moisture. 4MPL = geometric mean length as calculated by the ASAE (2001). |

||||

Effect of Moisture on Particle Size Measurement

We know that sample moisture content may affect sieving properties, but it is not practical to recommend that particle size estimation be conducted at a standardized moisture content (Finner et al., 1978). The PSPS is designed to describe particle size of the feed offered to the animal; thus, samples should not be chemically or physically altered before sieving. Because sample moisture loss may occur during storage or transport, a study was carried out to determine the effects of forage moisture on particle size measurement, as estimated by the PSPS. In the experiment, samples of both alfalfa haylage and corn silage were placed in a large forced air oven set at 55°C. Five times over a 48-hour period, samples of different moisture content were removed from the oven and analyzed for particle size using the PSPS.

Tables 2 and 3 outline the effects of forage moisture content on particle size estimated for both alfalfa haylage and corn silage. For alfalfa haylage, oven drying times of 0, 2, 6, 12, and 48 hours resulted in moisture concentrations of 57.4, 35.6, 10.4, 2.5, and 0.0%, respectively. Similarly, for corn silage, oven drying times of 0, 3, 6, 18, and 48 hours resulted in moisture concentrations of 58.0, 34.4, 14.6, 3.5, and 0.0%, respectively. For alfalfa haylage samples, particle size measurements were not significantly different between 57.4 and 35.6% moisture, indicating that moisture loss in samples within this range will not affect particle size measurements. Conversely, for corn silage, the amount of particle mass < 1.18 mm was significantly different between 58.0 and 34.4% moisture and resulted in a small but significant difference in MPL. These results suggest that moisture loss from corn silage may affect particle size results, but these differences, when observed, are small. For alfalfa haylage, compared to 57.4 and 35.6% moisture, the amount of material > 19.0 mm was significantly lower in samples containing 10.4, 2.5, and 0.0% moisture, but this difference was not observed for corn silage as most material > 19.0 mm contained cob particles for which size measurement appeared to be unaffected by moisture content. For both forages, amount of material < 1.18 mm was greatest at 0.0% moisture content, while MPL decreased with decreasing moisture content. These results are similar to those of Finner et al. (1978) who suggested that completely drying a sample results in shattering of particles and further size reduction during the sieving process. Differences in sieving results associated with sample drying may have been due to brittle particles that shatter during shaking or to decreased adhesion of small particles to larger ones when materials are dry.

| Particle size (mm) | Percent Moisture1 | SEM2 | P – value | ||||

|---|---|---|---|---|---|---|---|

| 57.4 | 35.6 | 10.4 | 2.5 | 0 | |||

| >19.0 | 61.5a | 63.0a | 45.2b | 40.3b | 27.5c | 2.87 | <0.001 |

| 19.0 – 8.0 | 25.3c | 24.4c | 35.4b | 37.3a,b | 44.5a | 2.25 | <0.001 |

| 8.0 – 1.18 | 11.3d | 10.6d | 15.1c | 18.0b | 22.6a | 0.69 | <0.001 |

| < 1.18 | 1.9c | 2.1c | 4.3b | 4.4b | 5.4a | 0.27 | <0.001 |

| MPL (mm)3 | 17.7a | 17.9a | 13.7b | 12.6b | 10.3c | 0.54 | <0.001 |

|

1Means in the same row with different superscripts differ (P < 0.05). 2SEM = standard of mean. 3MPL = geometric mean length as calculated by the ASAE (2001). |

|||||||

| Particle size (mm) | Percent Moisture1 | SEM2 | P – value | ||||

|---|---|---|---|---|---|---|---|

| 58.0 | 34.4 | 14.6 | 3.47 | 0 | |||

| >19.0 | 14.3 | 11.0 | 9.5 | 9.6 | 12.9 | 2.16 | 0.32 |

| 19.0 – 8.0 | 74.0a | 74.5a | 73.2a | 70.4a | 52.3b | 2.08 | <0.001 |

| 8.0 – 1.18 | 11.4d | 13.1c,d | 15.4b,c | 18.0b | 31.5a | 1.36 | <0.001 |

| <1.18 | 0.23d | 1.36c | 2.0b | 2.0b | 3.4a | 0.16 | <0.001 |

| MPL (mm)3 | 12.1a | 11.2b | 10.6b,c | 10.2c | 8.62d | 0.33 | <0.001 |

|

1Means in the same row with different superscripts differ (P < 0.05). 2SEM = standard error of mean. 3MPL = geometric mean length as calculated by the ASAE (2001). |

|||||||

Because it would be impractical to recommend a constant sample moisture for measuring forage or TMR particle size during field measurement, it is advantageous to know that slight losses of moisture have only limited effects on measurements according to the moisture range of this study. It is recommended that samples be analyzed in the same physical form as that fed to the animal and moisture loss in samples should be minimized. Based on our results, only small differences result when sample moisture loss is as much as 40% of the original sample.

Particle Size Recommendations

Table 4 contains the original particle size recommendations of corn silage, haylage, and TMR according to the Penn State Technical Bulletin, DAS 96-20 (Heinrichs, 1996). Although proven useful, the basis for the recommendations was simple surveys and field observations. More recently, a number of experiments have been conducted that have attempted to further understand the effects of forage and TMR particle sizes; thus, these recommendations have been revised and are listed in Table 5 and published in the newly revised Penn State Technical Bulletin, DAS 02-42 (Heinrichs and Kononoff, 2002).

| Type | |||

|---|---|---|---|

| Corn Silage1 | Haylage2 | TMR | |

| Sieve Size | Percentage retained | ||

| >19.0 mm | 2 – 4 | 15 – 25 | 6 – 10 |

| 19.0 – 8.0 mm | 40 – 50 | 30 – 40 | 30 – 50 |

| 8.0 – 1.18 mm | 40 – 50 | 40 – 50 | 40 – 60 |

|

1This recommendation applies if corn silage is not the sole forage used in the TMR; if corn silage is chopped and rolled, 10 to 15% may be > 19.0 mm. 2This recommendation applies if haylage is contained in a bunker silo; if it is in a sealed silo, 10 to 15% may be > 19.0 mm. |

|||

| Type | |||

|---|---|---|---|

| Corn Silage | Haylage | TMR | |

| Sieve Size | % of DM retained | ||

| >19.0 mm | 5 ± 3 | 15 ± 5 | 5 ± 3 |

| 19.0 – 8.0 mm | 55 ± 10 | 60 ± 15 | 40 ± 10 |

| 8.0 – 1.18 mm | 40 ± 10 | 30 ± 10 | 40 ± 10 |

| <1.18 mm | <5 | < 5 | < 20 |

| MPL (mm)2 | 8 ± 2 | 10 ± 2 | 5 ± 2 |

|

1As measured by the Penn State Particle Separator (Heirichs and Kononoff, 2002). 2MPL = geometric mean length as calculated by the ASAE (2001). |

|||

TMR Particle Size and Chewing Activity

It is widely understood that dairy cattle require fiber in a coarse physical form because it is effective in stimulating chewing activity, saliva secretion, and maintaining normal rumen health and function. As a result of this understanding, many studies have attempted to manipulate forage particle size to increase chewing activity and thereby increase the buffering capability in the rumen.

Recently, Krause et al. (2002a,b) demonstrated that feeding an alfalfa silage-based TMR with approximately 23% greater than 19.0 mm increased total chewing time 7.5 min/kg of DM consumed compared to a TMR which contained less than 1% greater than 19.0 mm. Similarly, Kononoff and Heinrichs (2003a) noted that increasing particle size of an alfalfa haylage-based TMR from 3 to 31% of the TMR greater than 19.0 mm increased chewing activity 6.7 min/kg of DM consumed. Taken together, these studies support the suggestion that the proportion of material retained on the top sieve of the PSPS is positively correlated to chewing activity (Krause et al., 2002b).

Differences in total time spent eating and ruminating are not always observed when feeding corn silage of different particle size. Bal et al. (2000) observed that fine cut length reduced eating activity but did not affect time spent ruminating; however, this has been reported by others (Schwab et al., 2002). In studies in which feed refusals were chemically analyzed (Bal et al., 2000; Kononoff and Heinrichs, 2003b), diets of longer particle size resulted in a higher concentration of NDF, indicating greater tendency for sorting. Based on these and other studies, it is apparent that increasing particle size of a TMR can increase chewing activity; however, if the TMR is too long, this may promote sorting behavior.

TMR Particle Size and Rumen pH

Nutritionists are often concerned about rumen pH because when pH levels fall below 6.0, fiber digestion may be impeded (Russell and Wilson, 1996). Generally speaking, rumen pH is a function of lactic acid and VFA production and is buffered by saliva (Maekawa et al., 2002). Because of this idea, it is common practice to feed diets of longer particle size and greater amounts of effective fiber so that saliva production is stimulated. In support of this understanding, Krause et al. (2002b) noted that intake of particles > 19.0 mm was negatively correlated to the amount of time rumen pH spent below 5.8. However, we also know that forage should not be harvested at excessively long lengths. Kononoff and Heinrichs (2003a) demonstrated that if diets are too long, eating patterns may be affected and may result in lower mean rumen pH even though chewing activity may be increased. In this study, increasing the proportion of particles > 19.0 mm from 3 to 12% did result in increased chewing activity and rumen pH. However, increasing the proportion of particles to 31% resulted in depressions in mean rumen pH, which was thought to be a result of changes in eating behavior and increased sorting.

In light of these studies, it is apparent that particle size can affect rumen pH; however, differences in particle size do not always result in differences in mean rumen pH. When evaluating a diet to determine a possible risk of subclinical acidosis, we should review levels of fiber and nonstructural carbohydrates, along with their associated fermentability (Yang et al., 2001a).

New Particle Size Recommendations

Our original particle size recommendations have been revised, and the amount of TMR > 19.0 mm has been reduced from the original recommendation. This is because literature demonstrates that when rations are correctly balanced for both fiber and nonstructural carbohydrates, no severe deleterious effects on rumen pH from reduced chewing activity are observed when rations contained less than 6% of the particles > 19.0 mm. Although many rations are commonly fed with longer particles, there is increasing evidence that these rations may result in increased sorting.

The recommended amount of material between 8.0 and 19.0 mm was maintained and reflected the variation commonly observed on commercial dairy farms (Heinrichs et al., 1999). As a result of the modification of the PSPS, particle size recommendations of material < 8.0 mm is now further partitioned into the proportion between 1.18 and 8.0 mm and the proportion < 1.18 mm. Given that no severe negative effects have been observed in animals consuming rations which contained 30 to 50% of the ration 1.18 to 8.0 mm, our recommendations are limited to that range (Kononoff and Heinrichs, 2003 a,b).

Few published studies have included the new sieve in particle size measurements; however, it is generally understood that particles retained on a 1.18 mm sieve pass out of the rumen slower than those not retained (Poppi et al., 1985). Recently, using a different method of dry sieving, Yang et al. (2001b) demonstrated that rumen outflow rate of particles less than 1.18 mm averaged 5.57%/h compared to those retained on a 3.35 mm sieve, which had an average outflow rate of 1.75%/h. Thus, the additional sieve should prove useful in further understanding of factors affecting rate of passage. Although the proportion of material < 1.18 mm was not different within two published experiments, no negative effects were observed when as much as 20% of the material was less than 1.18 mm (Kononoff and Heinrichs, 2003 a,b). We are thus currently limited to recommend that TMRs contain no more than 20% of the material < 1.18 mm. This recommendation may require further refinement based on the relative amounts of soluble and degradable carbohydrate components in the TMR.

Understanding Eating Behavior by Using the PSPS

Rations That Promote Sorting Behavior

Particle size analysis is only part of the story. Dairy rations must be balanced for proper nutrient intake, and as we all know, there is no standard ration. Given a ration which appears to be adequate in terms of its chemical composition, particle size results can aid in our understanding of how nutrients contained in the ration will be consumed by the animal. Further understanding of how particle size affects feeding behavior is warranted because if the ingestion of feed is more or less uniform, rumen fermentation will proceed with limited fluctuation in acid production. Alternatively, if ingestion is selective, fluctuations in ruminal acid production may result in imbalance, leading to abnormal or pathological conditions in the rumen (Van Soest, 1994). As a result of this, when attempting to identify limits to production, particle size evaluation should be included in our troubleshooting procedures.

Let’s look at an experimental situation in which lactating Holstein cows were fed one of two different rations that were chemically identical, but one was considered “long” and the other shorter but adequate according to our current guidelines. As presented in Table 6, the long ration contained 16% of the particles > 19.0 mm, while the short ration contained 7% of the particles > 19.0 mm. In both rations, the proportions of particles less than 1.18 mm were similar, approximately 4%. The cumulative percentage of material that falls through each sieve (cumulative percent undersize) is also presented in Table 6 and will be used for graphical purposes to be illustrated later. What can these measurements tell us about possible animal feeding behavior? In order for a ration that looks good on paper to work, it must be consumed. There is increasing understanding that the amount of particles > 19.0 mm is correlated with eating time and chewing behavior (Johnson et al., 2003). It is likely that this relationship is not perfectly linear, but as ration particle size increases, total chewing time should also increase, but only up to a point. Past this point, animals may then exhibit selective tendencies against longer, high fiber-containing particles. This is cause for concern because the ration was balanced with understanding that the animals would consume these longer particles.

| Short TMR | Long TMR | ||||

|---|---|---|---|---|---|

| Sieve Number | Particle Size (mm) | Percent Retained | Cumulative Percent Undersized | Percent Retained | Cumulative Percent Undersized |

| 1 | >19.0 | 7 | 93 | 16 | 84 |

| 2 | 19.0 – 8.0 | 56 | 37 | 50 | 34 |

| 3 | 8.0 – 1.18 | 34 | 4 | 30 | 4 |

| 4 | <1.18 | 4 | – | 4 | – |

Refusal Particle Size and Fiber Content

Now let’s evaluate the particle size of the remaining refusal after the animals have had a 24-hour access to the feed. Remember, we want the refusals to be similar to the feed originally fed; if it is drastically different (> 5% variation), animals may have sorted out the ration and consumed something different than what we originally assumed when we balanced the ration. As seen in Table 7, the particle size of the long TMR is much longer than that originally offered. From these observations, we can see that animals consuming the long ration consumed more grain, as 1% of the DM was less than 1.18 mm compared to 5% when animals consumed the short ration.

| Short TMR | Long TMR | ||||

|---|---|---|---|---|---|

| Sieve Number | Particle Size (mm) | Percent Retained | Cumulative Percent Undersized | Percent Retained | Cumulative Percent Undersized |

| 1 | >19.0 | 25 | 75 | 60 | 40 |

| 2 | 19.0 – 8.0 | 40 | 35 | 24 | 16 |

| 3 | 8.0 – 1.18 | 31 | 4 | 15 | 1 |

| 4 | <1.18 | 5 | – | 1 | – |

To support our observation that animals consuming the long ration exhibited an increased sorting tendency, we can evaluate the NDF content of the feed remaining in the bunk at 8, 16, and 24 hours after feeding. In our current example, the concentration of the original TMR for both long and short TMR was identical, 33% of DM. Data presented in Table 8 demonstrate that the NDF contents of the refusals at 24 hours after feeding for animals consuming the long TMR were 36 and 44% for the short and long TMR, respectively. After 24 hours for the long TMR remaining in the bunk, it was 11 percentage units greater in NDF than that originally fed, indicating considerable sorting activity. In comparison, the NDF content of the short feed remaining in the bunk was measured at 34, 36, and 36% at 8, 16, and 24 hours after feeding. This was very similar to the ration containing 33% NDF, indicating that very little sorting activity occurred. These data support our idea that particle size may affect how cows consume the ration and that feeding a ration that is too long or coarse may result in large amounts of sorting activity.

| Hours after Feeding | Short TMR | Long TMR |

|---|---|---|

| % NDF (DM basis) | ||

| 0 | 33 | 33 |

| 8 | 34 | 35 |

| 16 | 36 | 41 |

| 24 | 36 | 44 |

Using a Spread Sheet to Compare the TMR and Refusals

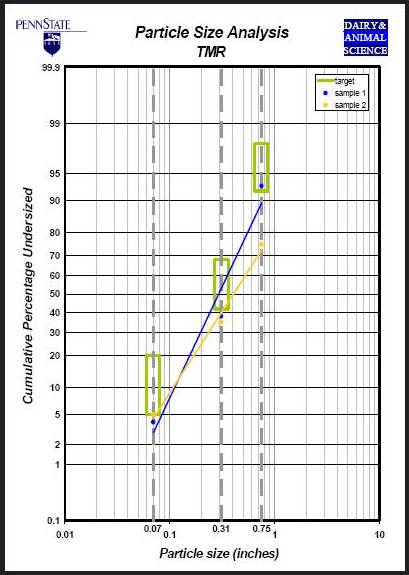

Additional tools and guidelines to be used in the evaluation of particle size are becoming available. A simple spreadsheet that performs all of the calculations while also graphing the results, can be downloaded from the Penn State Dairy Nutrition website. This spreadsheet can be used to gather information, while at the same time aid in further understanding feeding behavior. The size distribution of forage and TMR particles does not follow a normal distribution pattern; however, it can be plotted as a straight-line distribution using lognormal graphing paper. When plotting the data, sieve size is plotted on the horizontal, or X-axis, while the cumulative percentage of material that falls below each sieve is entered on the vertical, or Y-axis. Once entered into the PSPS spreadsheet, these values are then plotted, and a best-fit line is drawn between each of the three points. For example in Figure 1, approximately 16% of the feed is more than 19.0 mm (0.75 inches), and as a result, 84% of the material is undersized. With 50% being retained on the 8.0 mm (0.31 inches) sieve, a cumulative amount of 34% falls below 8.0 mm. Lastly, 23% is retained on the 1.18 mm sieve, and as a result, only 5% now falls less than 1.18 mm (0.05 inches).

Figures 1 and 2 illustrate the differences in particle size between the originally fed TMR and the refusals. In both figures, the original TMR particle size is plotted with dark points, and a best-fit line is drawn in the same color (upper line). Refusal particle size is plotted with lighter points, and a best-fit line is drawn in the same color (lower line). Generally, we would desire that each point remain in, or close, to the recommended rectangles and that the associated best-fit lines be very close together. When rations in which little sorting has occurred, such as that illustrated in Figure 1, points falling on the same X-axis will be close together. In rations that are severely sorted, as is Figure 2, the lighter refusal line is much lower than that of the original TMR line. To determine if sorting has occurred, compare the distance between the two points at each particle size (i.e., 1.18, 8.0, and 19.0 mm). In rations which result in a high degree of sorting, a greater spread between points will be observed.

Rations typically contain 40 to 60% concentrate, most of which passes through the sieve measuring 8.0 mm. Thus, the additional sieve will allow us to more precisely describe particle size by partitioning this fraction with the smaller sieve. Secondly, in Figure 1, the distance between the original TMR and refusal at >19.0 mm illustrates that some sorting of the material > 19.0 mm, but the proportion of particles < 1.18 mm was almost identical. This information indicated that, although some sorting activity occurred, especially with respect to those particles > 19.0 mm, the proportion of grain in the TMR and refusal was similar. In comparison, Figure 2 illustrates that the proportion of particles of all size ranges was different, including those < 1.18 mm. Thus, by including the additional sieve into our evaluation, we can more clearly see that the longer ration resulted in even greater selective tendency for the smaller grain particles.

Summary

The PSPS is a tool to quantitatively estimate forage and TMR particle size. As with any diagnostic tool, users of the PSPS must ensure correct operation. Because differences in the rate of shaking, or frequency of moving the device, may affect particle size estimations, we specify that the PSPS be shaken at a frequency of 1.1 Hz or greater (66 cycles/min) with a stroke length of 17 cm. Recently, we have also investigated the effects of sample moisture on measurements and determined that small amounts of moisture loss from collected samples may affect particle size results, but these differences, when observed, are small. Conversely, completely drying a sample resulted in large differences in particle size results. As a result of these observations, we recommend that samples be analyzed in the same form as fed to the animal, but precautions should be made so that moisture loss is minimized. In addition to these analytical recommendations, we have discussed the importance of particle size evaluation and outlined how the additional sieve and available spreadsheet may lead to further understanding of rumen fermentation and feeding behavior.

Author Information

P.J. Kononoff,

Renaissance Nutrition, Inc.

A.J. Heinrichs

Department of Dairy and Animal Science, The Pennsylvania State University

References

ASAE. 2001. Method of determining and expressing particle size of chopped forage materials by sieving. In Standards. Am. Soc. Agric. Eng., St. Joseph, Mich.

Bal, M.A., R.D. Shaver, A.G. Jirovec, K.J. Shinners, and J.G. Coors. 2000. Crop processing and chop length of corn silage: Effects on intake, digestion, and milk production by dairy cows. J. Dairy Sci. 83:1264-1273.

Finner, M.F., J.E. Hardzinski, and L.L Pagel. 1978. Evaluating particle length of chopped forages. ASAE paper No. 78-1047. Am. Soc. Ag. Eng., St. Joseph, Mich.

Heinrichs, A.J. 1996. Evaluating particle size of forages and TMRs using the Penn State Particle Size Separator. Technical Bulletin of The Pennsylvania State University, College of Agriculture Science, Cooperative Extension. DAS 96-20.

Heinrichs, A.J., D.R. Buckmaster, and B.P. Lammers. 1999. Processing, mixing, and particle size reduction of forages for dairy cattle. J. Anim. Sci. 77:180-186.

Heinrichs, A.J., and P.J. Kononoff. 2002. Evaluating particle size of forages and TMRs using the new Penn State Forage Particle Separator. Technical Bulletin of The Pennsylvania State University, College of Agriculture Science, Cooperative Extension. DAS 02-42.

Johnson, L.M., J.H. Harrison, D. Davidson, W.C. Mahanna, and K. Shinners. 2003. Corn silage management: effect of hybrid, chop length, and mechanical processing on digestion and energy content. J. Dairy. Sci. 86: 208-231.

Kononoff, P.J., and A.J. Heinrichs. 2003a. The effect of decreasing alfalfa haylage particle size on effective fiber values and ruminal fermentation. J. Dairy Sci. In Press.

Kononoff, P.J., and A.J. Heinrichs. 2003b. The effect of decreasing corn silage particle size and the inclusion of cottonseed hulls on effective fiber values and ruminal fermentation. J. Dairy Sci. In Press.

Kononoff, P.J., A.J. Heinrichs, and D. A Buckmaster. 2003. Modification of the Penn State forage and TMR separator and the effects of moisture content on its measurements. J. Dairy Sci. In Press.

Krause, K.M., D.K. Combs, and K.A. Beauchemin. 2002a. Effects of forage particle size and grain fermentability in midlactation cows. I. Milk production and diet digestibility. J. Dairy Sci. 85:1936-1946.

Krause, K.M., D.K. Combs, and K.A. Beauchemin. 2002b. Effects of forage particle size and grain fermentability in midlactation cows. II. Ruminal pH and chewing activity. J. Dairy Sci. 85:1947-1957.

Lammers, B.P., D.R. Buckmaster, and A.J. Heinrichs. 1996. A simplified method for the analysis of particle sizes of forage and total mixed rations. J. Dairy Sci. 79:922-928.

Maekawa, M., K.A. Beauchemin, and D.A. Christensen. 2002. Effect of concentrate level and feeding management on chewing activities, saliva production, and ruminal pH of lactating dairy cows. J. Dairy Sci. 85:1165–1175.

Poppi, D.P., R.E. Hendrickson, and D.J. Minson. 1985. The relative resistance to escape of leaf and stem particles from the rumen of cattle. J. Agric. Sci. 105:9-14.

Russell, J.B., and D.B. Wilson. 1996. Why are ruminal cellulolytic bacteria unable to digest cellulose at low pH? J. Dairy Sci. 79:1503-1509.

Schwab, E.C., R.D. Shaver, K.J. Shinners, J.G. Lauer, and J.G. Coors. 2002. Processing and chop length effects in brown-midrib corn silage on intake, digestion, and milk production by dairy cows. J. Dairy Sci. 85:613-623.

Van Soest, P.J. 1994. Nutritional Ecology of the Ruminant, 2nd Edition. Comstock Publishing Associated, a division of Cornell University Press, Ithaca, N.Y.

Yang, W.Z., K.A. Beauchemin, and L.A. Rode. 2001a. Effects of Grain Processing, Forage to Concentrate Ratio, and Forage Particle Size on Rumen pH and Digestion by Dairy Cows. J. Dairy Sci. 84:2203-2216.

Yang, W.Z., K.A. Beauchemin, and L.A. Rode. 2001b. Barley Processing, Forage:Concentrate, and Forage Length Effects on Chewing and Digesta Passage in Lactating Cows. J. Dairy Sci. 84:2709-2720.