Introduction

The dairy expansion era in North America, which gathered pace throughout the ’90s and continues to this day, has resulted in the migration of dairy cattle from traditional tiestall and stanchion barns to the freestall facility, which has emerged as the dominant form of dairy cattle housing worldwide.

The basic premise of milking more efficiently through a parlor, while being able to keep larger groups of cows together in management groups in larger herds, is sound from a management and economic perspective. Cows are “free” to move between a feed bunk where a total mixed ration (TMR) is available every hour of every day, and a stall, designed to provide her ample rest on a clean, dry, comfortable surface. This is the ideal. The question is whether it is the reality.

In this article, I will attempt to summarize the aspects of freestall design that are failing the cow and justify the solutions we have found and the current trends emerging in the dairy industry of the Upper Midwest. The challenge presented is to find the balance between excellent cow comfort and manageable cow cleanliness.

Please check this link first if you are interested in organic or specialty dairy production.

Freestalls and Time Budgets

So, what do cows do in the freestalls that we have built over the last 10 years? From an analysis of 250 total 24-hour time budgets we have collected from 208 cows housed in 17 freestall barns in Wisconsin, the average time spent performing each of five key behaviors is shown in Table 1. On average, cows spend 2.6 h/d milking, reflecting the three-times-a-day milking schedule most large freestall dairies operate at. Other components of the cow’s day are also fixed and nonnegotiable. The cow has to spend a large proportion of the day eating. The TMR-fed, freestall-housed dairy cow eats for an average of 4.4 h/d (range 1.4 to 8.1). Note that this is about half the time that a grazing cow spends eating per day; pasture cows average around 8 to 9 h/d eating. She also needs to drink around 20 to 25 gallons of water per day (more in hot climates), and she will spend an average of 0.4 h/d at or around a waterer. With these fixed nonnegotiable time slots, we have already taken 4.4 + 0.4 + 2.6 = 7.4 hours out of the time budget, leaving under 17 hours remaining in the pen.

Time left in the pen will be spent performing three activities – lying down, standing in an alley, and standing in a stall. The average freestall cow spends 2.4 h/d standing in an alley socializing, moving between the feed bunk and stalls, and returning from the parlor. Once in the stall, the average cow spends 2.9 h/d standing in the stall (range 0.3 to 13.0) and 11.3 h/d lying in the stall (range 2.8 to 17.6) on average – but note the wide ranges in these behaviors.

| Activity N = 250 | Mean (h/d) | Range (h/d) |

|---|---|---|

| Time lying down in the stall | 11.3 | 2.8-17.6 |

| Time standing in the stall | 2.9 | 0.3-13.0 |

| Time standing in the alley | 2.4 | 0.2-9.4 |

| Time drinking | 0.4 | 0-2.0 |

| Time feeding | 4.4 | 1.4-8.1 |

| Time milking | 2.6 | 0.9-5.7 |

Lying behavior is typically divided into an average of 7.2 visits to a stall each day (called a lying session), and each session is categorized by periods standing and lying (called bouts). The average cow has 13.6 lying bouts per day, and the average duration of each bout is 1.2 h (range 0.3 to 2.9). Most cows will stand after a lying bout, defecate or urinate, and lie back down again on the contra-lateral side.

From studies designed to make cattle work for access to a place to rest, it would appear that cows target around 12 h/d target lying time (Jensen et al., 2005; Munksgaard et al., 2005), and this is in agreement with the lying times found in well-designed freestall facilities (Cook et al., 2004). If this is the case, then our industry is failing to provide the average cow sufficient rest, and our freestall ideal is not being realized.

What Is the Cost of Inadequate Rest?

It is commonly suggested that cows make more milk when they are lying down, as blood flow through the external pudic artery increases by around 24 to 28% when lying compared to standing up (Metcalfe et al., 1992; Rulquin and Caudal, 1992), and failure to achieve adequate rest has negative impacts on lameness (Cook and Nordlund, In Press), ACTH concentrations (Munksgaard and Simonsen, 1996), cortisol response to ACTH challenge (Munksgaard et al., 1999), and growth hormone concentrations (Munksgaard and Løvendahl, 1993; Ingvartsen et al., 1999), suggesting that there is a significant stress response.

Some workers have suggested a linear relationship between time lying and milk production of the order of 2 to 3.5 lb of milk increase for each additional hour of rest (Grant, 2004). While this may be true, we have not seen such a relationship, and milk yield has not been significant in any of the lying time models in our time budget studies.

It seems more likely that the requirement for rest is a threshold event, and that all cows, regardless of yield, require a minimum period. A strong case can be made that the true cost of failing to achieve this rest is an increase in lameness, and lameness has significant impacts on production.

Let us take a look at mature equivalent (ME305) milk production (which standardizes milk output to third parity) and see how well older cows perform compared to younger cows – as a proxy measure of how successful our lameness management is.

ME305 averages for two groups of herds using Wisconsin DHIA testing – less than 100 cows (which we will assume are predominantly tiestall housed) and greater than 500 cows (which we will assume are freestall housed) are shown in Table 2. There are some interesting trends in the difference between second and later lactation groups and first lactation groups. While the freestall-housed larger herds make more milk, and the difference in ME between first and second parity is similar (~500 to 600 lb) between both herd-size groups, the difference between first lactation and third and greater lactation cows is much wider in the large herd category – nearly 1,300 lb greater. If this were due to a failure of the ME calculation to properly account for parity effects, we would expect the differences to be consistent across herd size. They are not, and I believe that the greater differences we are seeing in larger herds are due to the environment in which we are keeping the animals. Significant differences in lameness prevalence have been recorded between tiestall and freestall barns (Wells et al., 1993; Bergsten and Herlin, 1996; Cook, 2003; Sogstad et al., 2005), and evidence exists to suggest that the freestall environment is failing the larger, older cows in our herds – lameness being the primary reason for the disparity in ME milk production. In barn remodels, where we provide more comfortable stalls for older, mature cows, we see the ME gap close and sometimes invert. This occurs coincidentally with a decrease in lameness prevalence, particularly in older cows.

| Parity Group | Mature Equivalent 305 Milk Production (lb) | |||

|---|---|---|---|---|

| Herds <100 cows (n = 3218) | Herds >500 cows (n = 155) | |||

| Average | Difference from 1st Lact | Average | Difference from 1st Lact | |

| 1st Lactation | 22,903 | – | 29,084 | – |

| 2nd Lactation | 22,374 | 529 | 28,462 | 622 |

| 3rd+ Lactation | 21,859 | 1,044 | 26,783 | 2,301 |

So what can we do to improve the situation? We can certainly make sure that there is adequate time for rest by limiting time out of the pen for milking, providing enough stalls for cows to achieve their target rest by limiting overstocking, and, finally, by making sure that the stall is comfortable and easy to use. Indeed, we have used the ME gap theory described above to help justify many stall renovation projects.

The Importance of Stall Surface

Analysis of our time budget database highlights the importance of stall surface. Cows bedded on sand exceeded our target of 12 h/d of rest, while cows on rubber crumb-filled mattresses averaged only 10.7 h/d (Figure 1).

The reason for this is two-fold. First, there are on average 42% fewer lame cows in sand-bedded freestall herds (Cook, 2003, Cook et al., 2004, Espejo et al., 2006); secondly, lame cows stand for longer in mattress stalls compared to sand stalls. We believe that the main reason for this is due to the difficulties lame cows have rising and lying down on a firm surface (Cook and Nordlund, In Press). While sand provides cushion, traction, and support, which facilitates rising and lying movements for lame cows, enabling them to maintain normal patterns of rest, firm mattress surfaces make it difficult for cows to rise and lie down because of the pain associated with the contact point between a painful foot and a firm, unforgiving surface. As a result, we see an extension in standing time per day, a reduction in the number of visits to a stall per day, and, as a consequence of three-times-a-day milking schedule and other stresses to the cow’s time budget, a reduction in lying time. Failure to provide adequate rest and recuperation for lame cows results in chronic disease and an increase in the prevalence of lameness.

The difference in lameness prevalence is the main reason for the large difference in milk production observed between sand and mattress freestalls (Table 3), in addition to benefits in terms of milk quality. The numbers presented in Table 3 are for herds visited because of an udder health problem. However, the differences observed are very typical of the mattress-to-sand conversions we have been involved in over the last five years, and we use these figures for the construction of partial budgets to finance the barn changes.

| Factor | Mattress Herds | Sand Herds | Sand Benefit |

|---|---|---|---|

| RHA milk production per cow (lb) | 24,260 | 25,926 | +1,666 |

| Somatic Cell Count (‘000/ml) | 373 | 298 | -75 |

| Cow Case Mastitis Rate (%) | 62 | 45 | -17 |

Sand must be managed to prevent a buildup of organic material over time (Cook and Reinemann, 2007). Provided fresh sand is added once or twice a week, gross contamination is removed each milking, the bed is leveled daily, and sand is removed from the rear of the beds every six months or so, it remains the gold standard for the cow, not only in terms of comfort but also in terms of milk quality. While organic bedding materials may be “managed,” I find them in every way inferior to sand, particularly when managed in a deep, loose bed.

Because sand is so forgiving, it has often been said that the cow may compensate for other failures in stall design, such as inadequate space. In fact, I used to think the same – but I do not anymore. We have seen too many improvements in production and health in sand-bedded facilities when other stall design improvements have been made.

Providing Adequate Width

The freestall barns built throughout the expansion era have typically had resting spaces defined laterally by divider loops located at 43 to 46 inches (109 to 117 cm) on center and by a brisket board typically 66 inches (168 cm) from the rear curb. While we believe that these dimensions are appropriate for a 1,200 lb (545 kg) first lactation heifer, we believe that they are inadequate for larger, mature cows. The evidence for such an opinion comes from three sources:

- Direct observation: Anderson (2003) examined the ergonomics of stall design and showed how limited resting space increased the disturbances between neighbors and led to more restless lying behavior.

- Behavioral studies: The stall behavior studies described by Tucker et al. (2004) used 15 Holstein cows averaging ~1,600 lb (727 kg) body weight and showed a significant increase in resting time between 44-inch (112 cm) and 48-inch (122 cm) wide stalls but no difference between 48 (122 cm) and 52 inches (132 cm), proving that width does have a significant effect on lying behavior and supporting wider dimensions than the industry standard of ~45 inches (114 cm).

- Herd performance changes after stall remodeling: We have remodeled a large number of freestall facilities in the Upper Midwest over the last five years, and my experience has been that after stall surface changes, increased stall width for large, mature Holstein cows has been the second most important change made in both sand and mattress facilities.

There is a commonly held belief that if we make the stall wider and longer, it will lead to increased manure contamination of the stall, inappropriate stall use behavior (e.g., backwards lying) and worsening udder health. If the stall is not sized appropriately for the size of the animals using them and if the resting area is poorly defined, these concerns may well be realized. It is therefore important to determine the size of the animals using the pen and to design the resting space correctly. Problems do occur when mixed age groups are penned together. While small heifers in larger stalls may well soil the platform more, it makes no sense to punish two-thirds of a pen of mature cows to make sure the stalls are kept clean for the heifers. A compromise must be reached – either with stall dimensions or cow grouping strategy.

Diagonal lying is a complex behavioral issue resulting from a variety of stall design faults, but stall width is often blamed. I believe that the most significant issues leading to diagonal lying are unrelated to stall width. They include adjacent cows in head-to-head stalls (Anderson, 2003), too short a resting space length, brisket locators that are too high, inadequate lunge space, head bob restrictions, and neck rails that are too close to the rear curb (Cook and Nordlund, 2005). Failure to understand these causative factors results in poorly designed stalls where cows become contaminated with manure. Therefore, we need to make sure that the resting area is correctly defined, so that manure contamination of the bed can be minimized.

Defining the Resting Area

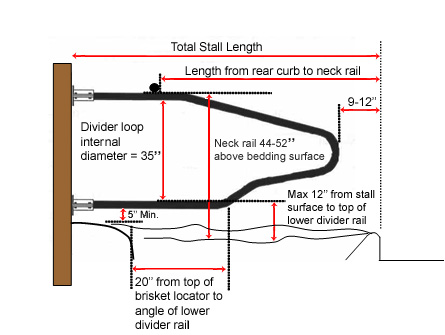

The stall resting space is defined laterally by the divider loop and in front by the brisket locator. We need to provide just enough direction to align the cow correctly in the stall but not inhibit the boundaries of the area so much that lying and rising behavior has to be modified to the point that it reduces the ability of the cow to use the stall. For these reasons, we prefer a divider loop that has the following characteristics (Figure 2):

- Locates the upper edge of the lower divider rail at 12 inches (30 cm) above the stall surface. This serves to align the cow, enables the cow to lunge easily to the side over the top of the rail if she chooses to do so, and is high enough to reduce trauma to the front leg below the rail and limit cows putting their legs through the loop.

- Has an angle in the lower rail that is located 20 inches (51 cm) behind a correctly located brisket locator. This location serves to align the cow but limits trauma to the hip area.

- Has an interior loop diameter of 35 inches (89 cm) or exterior diameter of 39 inches (99 cm). This will make sure that, with the lower rail correctly located, the upper rail will place the neck rail at around 50 inches (127 cm) above the stall surface.

The resting space is defined in front by the brisket locator, which serves to position the cow when she is resting so that her rear end is adjacent to the alleyway to reduce soiling of the bedding. Behavioral studies have shown that cows prefer to lie in stalls without a brisket locator, compared to stalls with an 8 inch (20 cm) high piece of wood (Tucker et al., 2006). Many consultants have taken this to mean that we should build stalls without brisket locators. This is a mistake. I will concede that in a short stall (less than 8 feet [2.44 m]), a poorly designed brisket locator can be removed, resulting in an observable improvement in stall usage, but larger stalls require a locator to help position the cow.

The problem with brisket locator design is the movement of the cow’s front leg when she is rising in the stall. To facilitate rising, she needs to take a full forward stride, and to do this, it is difficult for most cows to lift their leg much higher than about 4 inches (10 cm) above the stall surface. Generally, we have moved away from the traditional brisket board (a wooden form used to pour the concrete curb) to more rounded plastic, fiberglass, or PVC pipes or mouldings. These have performed reasonably well, but because they are lower, smoother, and less restrictive, some cows choose to ignore them. Because of these issues, we have returned to concrete for the answer, and I have developed a design that we call the “brisket slope.” This serves to locate the cow, while being low enough to allow the cow to lie down with her front legs outstretched, and sloped enough to allow the front leg to land on the slope when rising (Figure 3).

Providing Adequate Lunge and Bob Space

When the cow rises, she moves her head forward in a lunging motion to take the weight off her rear legs, to facilitate rising. The head is lowered, almost to the surface she is resting on, and then “bobs” upward. We refer to the horizontal area in front of the resting space as lunge space and the vertical area at the end of the lunge as the bob zone.

Failure to provide adequate lunge and bob space may not result in a dramatic reduction in stall occupancy, but it does alter the way cows use the stalls in subtle ways. Tucker et al. (2004) found no effect on lying times for ~1,600 lb (727 kg) cows housed in stalls 90 inches (2.29 m) long or 108 inches (2.74 m) long. There are three possible reasons for this: a) it doesn’t matter, b) neither of the choices were long enough for front lunge (our recommendation is for cows weighing ~1,600 lb (727 kg) to be housed in stalls 120 inches (3.05 m) long, or c) the cows could side lunge because the lower divider loop rail was correctly located to allow this option. I believe that “b” and/or “c” are the most likely explanations.

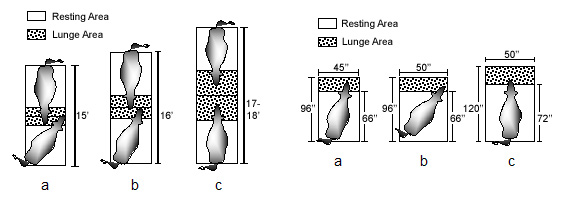

Having seen the results of numerous barns that have extended side walls to allow 9.5 to 10 feet (~3.0 m) long side wall stalls, I am convinced that it does make a difference, especially for the largest, oldest cows on the farm. I am also convinced that some cows will want to side lunge, and we should allow that as an option. This is particularly true of head-to-head stalls. The presence of one cow in front of another adds an element of uncertainty in stall design in that some cows will not lie straight or lunge into a cow facing her. This leads to diagonal lying and side lunging. This also has an effect on how clean the stalls are if we change stall dimensions. In order to maximize width without running into diagonal lying issues, we must provide adequate length for front lunge. For mature Holstein cows, that means stalls that are 10 feet (3.05 m) long facing a wall and at least 17 feet (5.18 m) head to head (Figure 4).

Locating the Neck Rail

The neck rail serves to provide lateral stability to the divider loops while helping to position the cow while standing in the stall relative to the rear curb. It is important to realize that the cow on pasture rises and ends up standing 2 to 3 feet (60 to 90 cm) in front of where she was lying. Therefore, wherever we place the neck rail, it will be in the way of the cow – even if it is “floating” or is made of some material other than metal. The trick is to locate it so that the cow can cope and adjust and take a step backward rather than a step forward when she rises. Neck rails do not influence lying time much, but they do influence standing behavior when located between 55 inches (140 cm) and 92 inches (234 cm) from the rear curb and between 40 inches (102 cm) and 50 inches (127 cm) above the stall surface (Tucker et al., 2005), with lower rails closer to the rear curb increasing the amount of perching (standing half in and half out of the stall) observed. We associate these neck rail locations with a greater risk for injury also.

Neck rails that are located too far forward increase soiling of the stall bed and frequently farmers respond by moving the rail back closer to the curb. However, if there is insufficient space to rise comfortably below and behind the neck rail, cows have difficulty standing without hitting the rail – which is just unacceptable. While a contaminated stall may be a risk for udder infection, an unused stall is most definitely a risk for inadequate rest, lameness problems, and early herd removal. We therefore have to find the right balance between comfort and cleanliness.

Neck rail location recommendations are different in mattress and sand stalls because the raised rear curb modifies the way cows stand in the stall – they are reluctant to stand on a raised concrete curb. Neck rails are located in mattress stalls directly above the correctly located brisket locator so that the cow is able to stand squarely in the stall, but in deep bedded stalls with a raised rear curb, where the neck rail is at least 48 inches (122 cm) above the surface, we move the rail back a distance equivalent to the width of the rear curb so that the cow takes a step back and perches half in and half out of the stall. While we will not tolerate this behavior in a flat, mattress stall, we are prepared to tolerate it in a deep, loose-bedded stall because the front foot elevation is much less and the problems of managing a deep bed soiled with urine and feces are too great. While there is some evidence to suggest extended time perching increases the risk for lameness (Weary, personal communication), this does not seem to be a factor in sand stalls as 90% of the stall standing behavior is perching (Cook et al., 2005) and lameness prevalence is almost half of that on mattresses. This probably relates to the fact that stall standing time is about half in sand stalls compared with mattress stalls.

| Stall Dimension (inches) | Body Weight Estimate (lb) | ||||

|---|---|---|---|---|---|

| 1000 | 1200 | 1400 | 1600 | 1800 | |

| Total stall length facing a wall | 96 | 96 | 108 | 120 | 120 |

| Distance from rear curb to brisket locator | 64 | 66 | 68 | 70 | 72 |

| Center-to-center stall divider placement (stall width) | 44 | 46 | 48 | 50 | 54 |

| Height of brisket locator above stall surface | 3 | 3 | 4 | 4 | 4 |

| Height of upper edge of bottom divider rail above stall surface | 11 | 11 | 12 | 12 | 12 |

| Height below neck rail | 44 | 46 | 48 | 50 | 52 |

| Horizontal distance between rear edge of neck rail and rear curb for mattress stalls | 64 | 66 | 68 | 70 | 72 |

| Rear curb height | 8 | 8 | 8 | 8 | 8 |

Conclusion

I believe that stall designs which were commonplace in freestall barns up until a few years ago are failing the cow and our industry in terms of performance, health, and well-being. We can and should do better, and it is economic to do so. Numerous barn renovations have proven this to be the case. However, doing what is right for the cow is not solely an economic question. Welfare has never been and never will be an argument based on economics. It is a duty that transcends such discussion. Fortunately, the balance of welfare and economics is in alignment when we consider improvements to cow comfort.

It is true to say that when we make stalls bigger, there is greater risk for design error, leading to diagonal lying and manure contamination of the stall bed. However, it is also true that a “one-size-fits-all policy of restraint” has also failed. In this discussion, I have detailed the common errors made when making stalls bigger – using the wrong divider loop, not using a brisket locator or using a poorly designed one, failing to understand the importance of forward lunge and bob space to lying position, and locating the neck rail incorrectly. Such problems are common because builders and farmers have not built such large stalls before, and there is much confusing misinformation about new design philosophies. It is hoped that this article has put some of these issues to rest.

Author Information

Nigel B. Cook

University of Wisconsin-Madison,

School of Veterinary Medicine

References

Anderson, N. 2003. Dairy cattle behavior: Cows interacting with their workplace. Pages 10-22 in Proc. 36th Annual Convention American Association of Bovine Practitioners, Columbus, Ohio.

Bergsten, C., and A.H. Herlin. 1996. Sole hemorrhages and heel horn erosion in dairy cows: The influence of housing system on their prevalence and severity. Acta Veterinaria Scandinavia 37:395-408.

Cook, N.B. 2003. Prevalence of lameness among dairy cattle in Wisconsin as a function of housing type and stall surface. Journal of American Veterinary Medical Association 223:1324-1328.

Cook, N.B., T.B. Bennett, and K.V. Nordlund. 2004. Effect of free stall surface on daily activity patterns in dairy cows, with relevance to lameness prevalence. J. Dairy Sci. 87:2912-2922.

Cook, N.B., and K.V. Nordlund. 2005. An update on dairy cow freestall design. Bovine Practitioner 39:29-36.

Cook, N.B., T.B. Bennett, and K.V. Nordlund. 2005. Monitoring indices of cow comfort in free-stall housed dairy herds. J. Dairy Sci. 88:3876-3885.

Cook, N.B., and D. Reinemann. 2007. A tool box for assessing cow, udder and teat hygiene. Pages 31-43 in 46th Natl. Mastitis Counc. Mtg. Proc. San Antonio, Texas. Natl. Mastitis Council Inc., Madison, Wis.

Cook, N.B., and K.V. Nordlund. In press. The influence of the environment on dairy cow behavior, claw health and herd lameness dynamics. Vet. J. doi:10.1016/j.tvjl.2007.09.016.

Espejo, L.A., and M.I. Endres. 2007. Herd-level risk factors for lameness in high-producing Holstein cows housed in freestall barns. J. Dairy Sci. 90:306-314.

Grant, R. 2004. Taking advantage of natural behavior improves dairy cow performance. Accessed 08/22/08 at http://www.extension.org/pages/Taking_Advantage_of_Natural_Behavior_Improves_Dairy_Cow_Performance.

Ingvartsen, K.L., L. Munksgaard, V.K.M. Nielsen, and L. Pedersen. 1999. Responses of repeated deprivation of lying down on feed intake, performance and blood hormone concentration in growing bulls. Acta. Agric. Scans. A. Anim. Sci. 49:260-265.

Jensen, M.B., L.J. Pedersen, and L. Munksgaard. 2005. The effect of reward duration on demand functions for rest in dairy heifers and lying requirements as measured by demand functions. Appl. Anim. Behav. Sci. 90:207-217.

Metcalfe, J.A., S.J. Roberts, and J.D. Sutton. 1992. Variations in blood flow to and from the bovine mammary gland measured using transit time ultrasound and dye dilution. Res. Vet. Sci. 53:59-63.

Munksgaard, L., L. Ingvartsen, L.J. Pedersen, and V.K.M. Nielsen. 1999. Deprivation of lying down affects behavior and pituitary-adrenal axis responses in young bulls. Acta. Agric. Scand. A. Anim. Sci. 49:172-178.

Munksgaard, L., and P. Løvendahl. 1993. Effect of social and physical stressors on growth hormone levels in dairy cows. Can. J. Anim. Sci. 73:847-853.

Munksgaard, L., and H.B. Simonsen. 1996. Behavioral and pituitary adrenal-axis responses of dairy cows to social isolation and deprivation of lying down. J. Anim. Sci. 74:769-778.

Munskgaard, L., M.B. Jensen, L.J. Pedersen, S.W. Hansen, and L. Matthews. 2005. Quantifying behavioural priorities: effects of time constraints on behavior of dairy cows. Appl. Anim. Behav. Sci. 92:3-14.

Phillips, C.J.C., and M.I. Rind. 2001. The effects on production and behaviour of mixing uniparous and multiparous cows. J. Dairy Sci. 84:2424-2429.

Rulquin, H., and J.P. Caudal. 1992. Effects of lying or standing on mammary blood flow and heart rate of dairy cows. Ann. Zootech. (Paris) 41:101.

Sogstad, A.M., T. Fjeldaas, O. Osteras, and K. Plym Forshell. 2005. Prevalence of claw lesions in Norwegian dairy cattle housed in tie stalls and free stalls. Preventive Veterinary Medicine 70:191-209.

Tucker, C.B., D.M. Weary, and D. Fraser. 2004. Free-stall dimensions: effects on preference and stall usage. J. Dairy Sci. 87:1208-1216.

Tucker, C.B., D.M. Weary, and D. Fraser. 2005. Influence of neck rail placement on freestall preference, use and cleanliness. J. Dairy Sci. 88:2730-2737.

Tucker, C.B., G. Zdanowicz, and D.M. Weary. 2006. Brisket boards reduce freestall use. J. Dairy Sci. 89:2603-2607.

Wells S.J., A.M. Trent, W.E. Marsh, and R.A. Robinson. 1993. Prevalence and severity of lameness in lactating dairy cows in a sample of Minnesota and Wisconsin dairy herds. Journal of American Veterinary Medical Association 202:78-82.